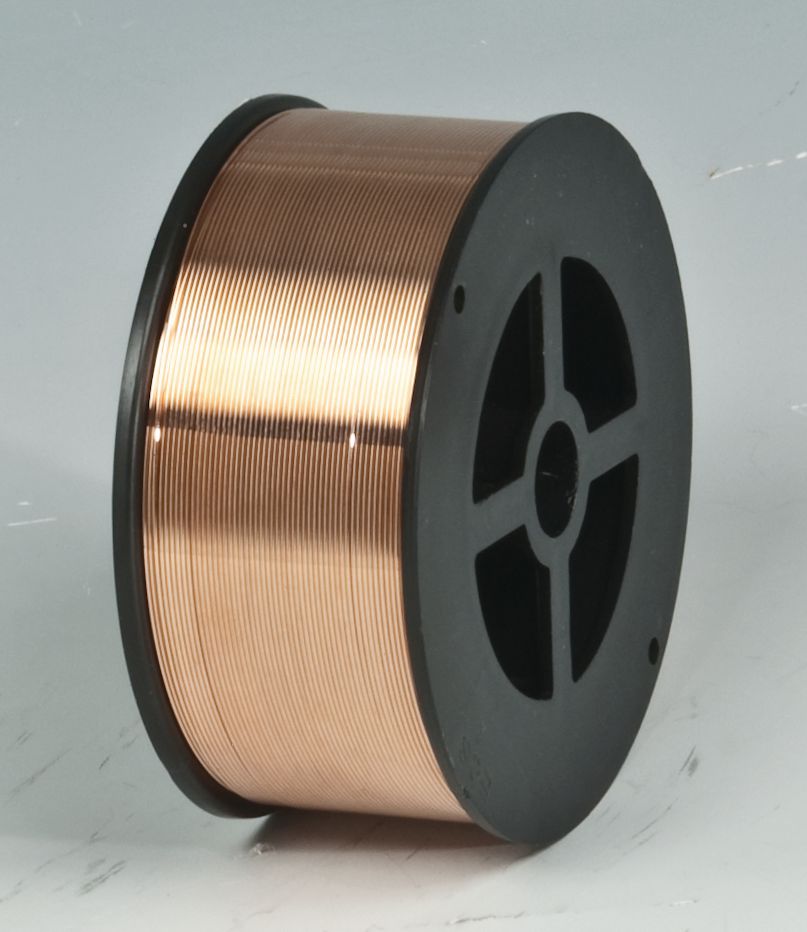

345 Tool Steel TIG Wire, Solid, 54 to 58 HRC Hardness, 100% Ar Shielding Gas, DCSP Polarity, 36" Length, 3/32"

(Pack of

2)

A broad selection of premium alloys to use for nearly any tool steel application and repair.

Superior Advantages

• Crack-resistant

• Premium operability

• High wear resistance

Hardness: Rc 54-58

Polarity: DC Straight

Gas: 100% Ar

Universal and “H” Series, Chromium Hot Work Tool SteelThe principal elements in this alloy are chromium, tungsten, moly and vanadium. This chemistry provides an extremely tough deposit with deep air-hardening capabilities up to 12". Types: H11, 12, 13, S1, S7, 01, 06.

Typical Applications

• Various tool steel repairs – specific alloy selection is dependent upon the type (or Series) of tool steel being repaired

• Forming dies, cutting tools and high impact tools

Couldn't load pickup availability

California Proposition 65: WARNING: Cancer -

www.P65Warnings.ca.gov

Frequently Bought Together

Radiator Grille Nut M4.2-1.41

Couldn't load pickup availability

Front Bumper Push-Type Retainer Nylon 20mm

Couldn't load pickup availability

Metric Indented Hex Head Bolt with 17mm Washer

Couldn't load pickup availability

345 Tool Steel TIG Wire 0.035"

Couldn't load pickup availability

344 Tool Steel TIG Wire 3/32"

Couldn't load pickup availability

344 Tool Steel Stick Rod Electrode 1/8"

Couldn't load pickup availability

Spring Loaded Trigger Torch Lighter

Couldn't load pickup availability

1/4 on 1/4 Dimension I Single Pass Overlay

Couldn't load pickup availability

1/8 on 1/4 Dimension I Single Pass Overlay

Couldn't load pickup availability

321 Mild and Carbon Steel MIG Welding Wire 0.03"

Couldn't load pickup availability

E7024Mild /Carbon Steel Stick Electrode 3/16"

Couldn't load pickup availability

211 Cast Iron TIG Wire 1/8"

Couldn't load pickup availability

Product Description

A broad selection of premium alloys to use for nearly any tool steel application and repair.Superior Advantages

• Crack-resistant

• Premium operability

• High wear resistance

Hardness: Rc 54-58

Polarity: DC Straight

Gas: 100% Ar

Universal and “H” Series, Chromium Hot Work Tool SteelThe principal elements in this alloy are chromium, tungsten, moly and vanadium. This chemistry provides an extremely tough deposit with deep air-hardening capabilities up to 12". Types: H11, 12, 13, S1, S7, 01, 06.

Typical Applications

• Various tool steel repairs – specific alloy selection is dependent upon the type (or Series) of tool steel being repaired

• Forming dies, cutting tools and high impact tools

Technical Specifications

| Item#: | CW1889 |

|---|---|

| Welding Process | TIG |

| Type | Solid |

| Diameter | 3/32 " |

| Length | 36 " |

| Base Metal | Tool Steel |

| Hardness | 54-58 HRC |

| Shielding Gas | 100% Ar |

| Polarity | DCSP |

| Quantity Per Package | 2.0000 |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 0.5 lb |

Product Restrictions

California Proposition 65: WARNING: Cancer -

www.P65Warnings.ca.gov