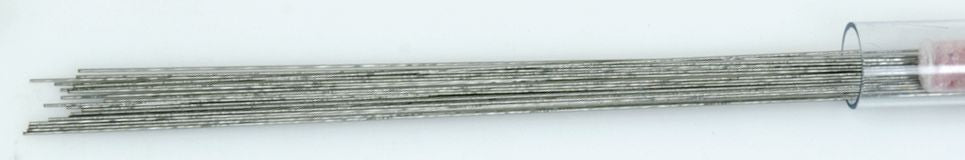

349 Tool Steel TIG Wire, Solid, 33 to 36 HRC Hardness, 100% Ar Shielding Gas, 26% Elongation, 36" Length, 0.035"

(Pack of

1)

Specially formulated for welding P-mold steels and most chrome-moly alloy steels.

Superior Advantages

• Crack-resistant

• Premium operability

• High wear resistance

Tensile Strength: 89,700 PSIYield Strength: 73,400 PSIElongation: 26%Hardness: Rc 33-36Polarity: DC StraightGas: 100% Ar

Typical Applications

• Die-casting dies

• Injection molds

• Compression molding of plastics and chrome-moly steels like AISI 4130, 4140, 8620 and 8640

Usage ProcedureMaintain a short arc with minimal weave. Preheat as prescribed by base metal.

Couldn't load pickup availability

California Proposition 65: WARNING: Cancer -

www.P65Warnings.ca.gov

Frequently Bought Together

Front Fender Push-Type Retainer Nylon 20mm

Couldn't load pickup availability

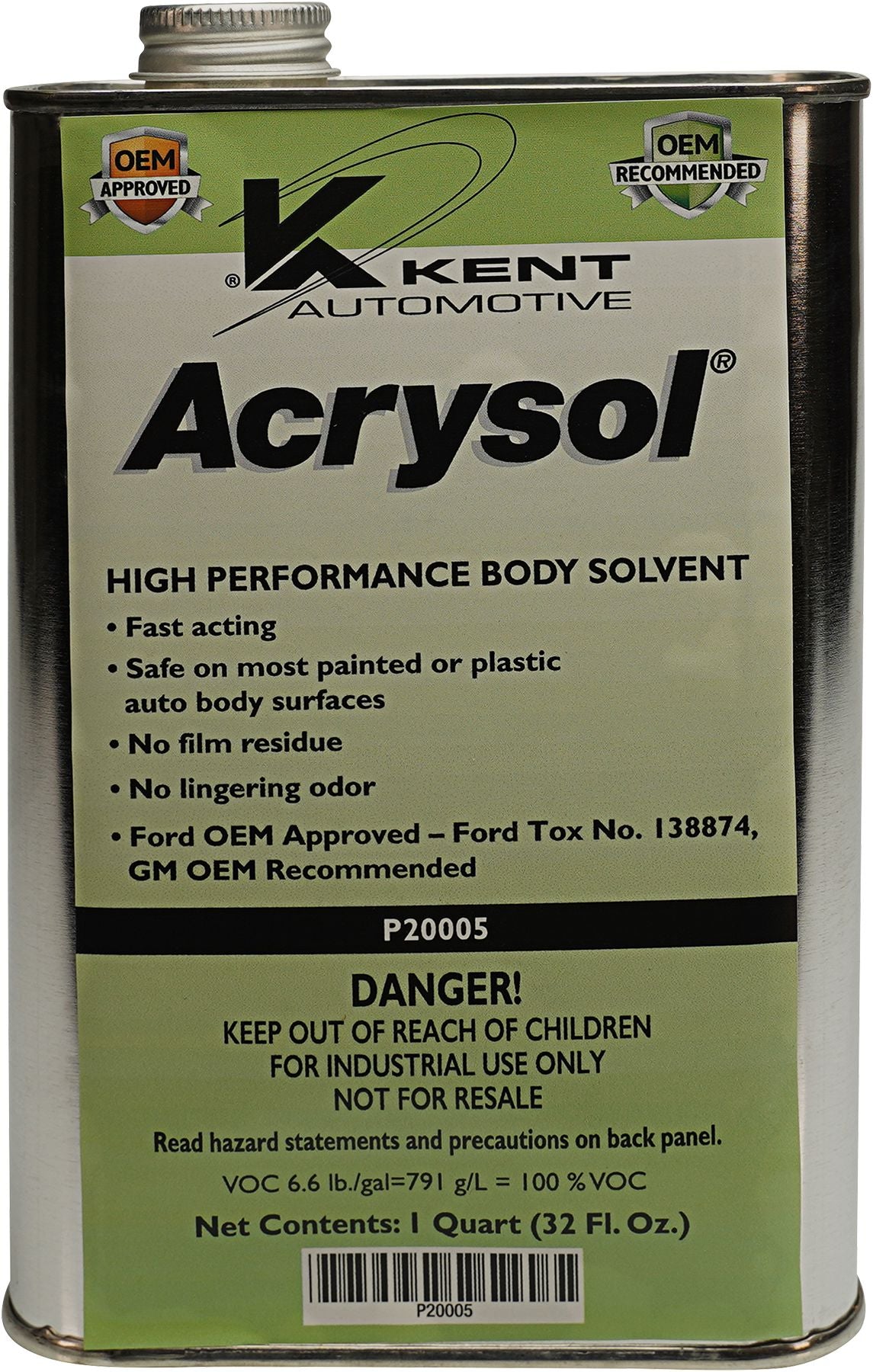

Acrysol Paint Preparation and Auto Body Solvent

Couldn't load pickup availability

Drive Rivet Nylon M8

Couldn't load pickup availability

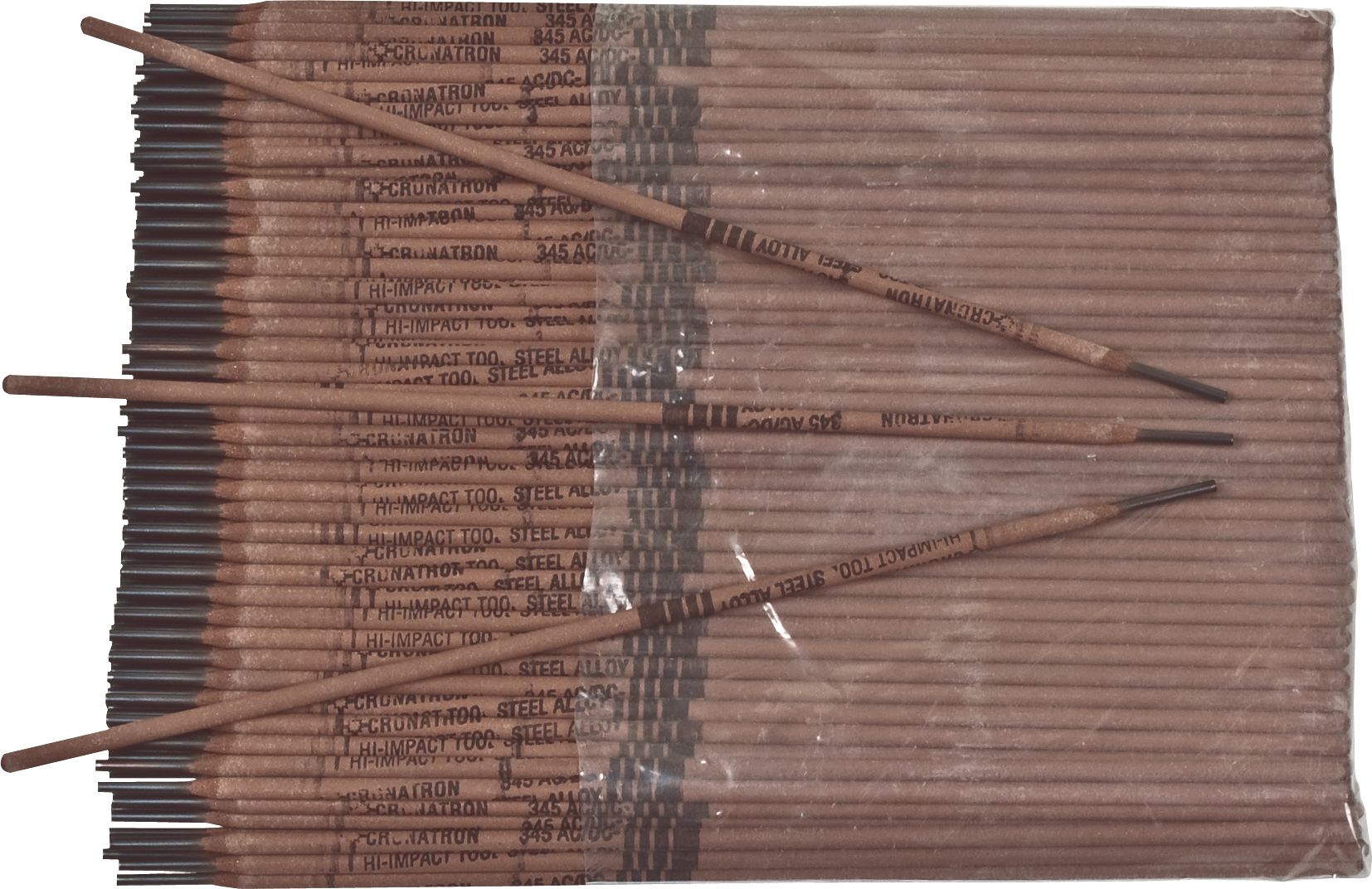

345 Tool Steel Stick Rod Electrode 3/32"

Couldn't load pickup availability

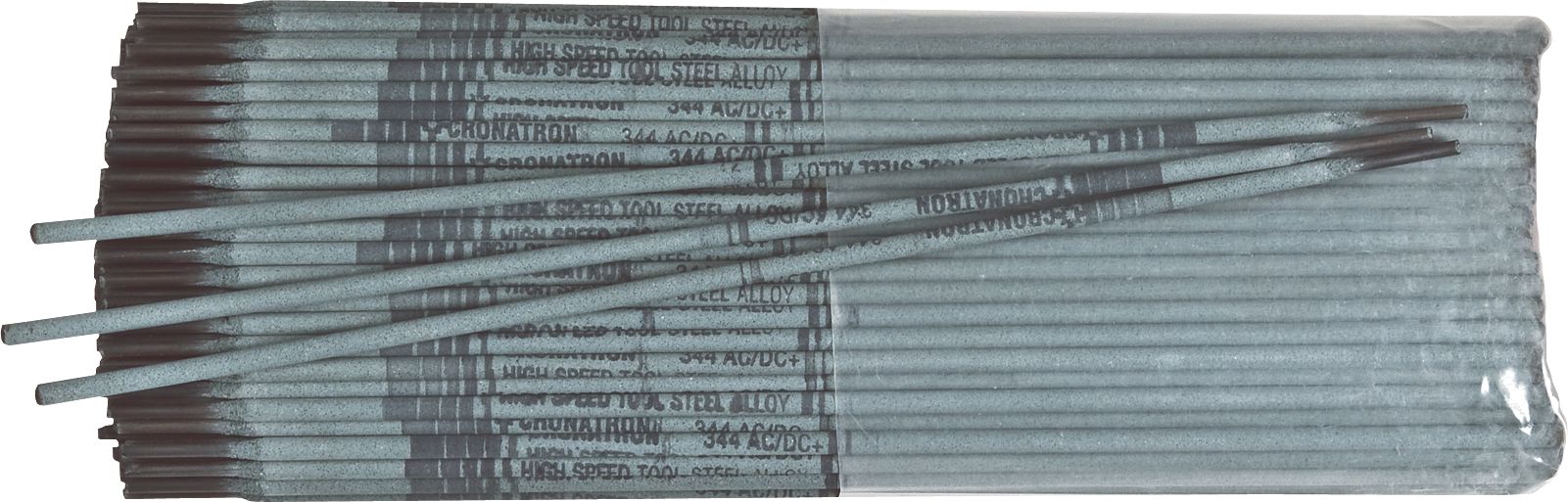

344 Tool Steel Stick Rod Electrode 3/32"

Couldn't load pickup availability

349 Tool Steel TIG Wire 0.02"

Couldn't load pickup availability

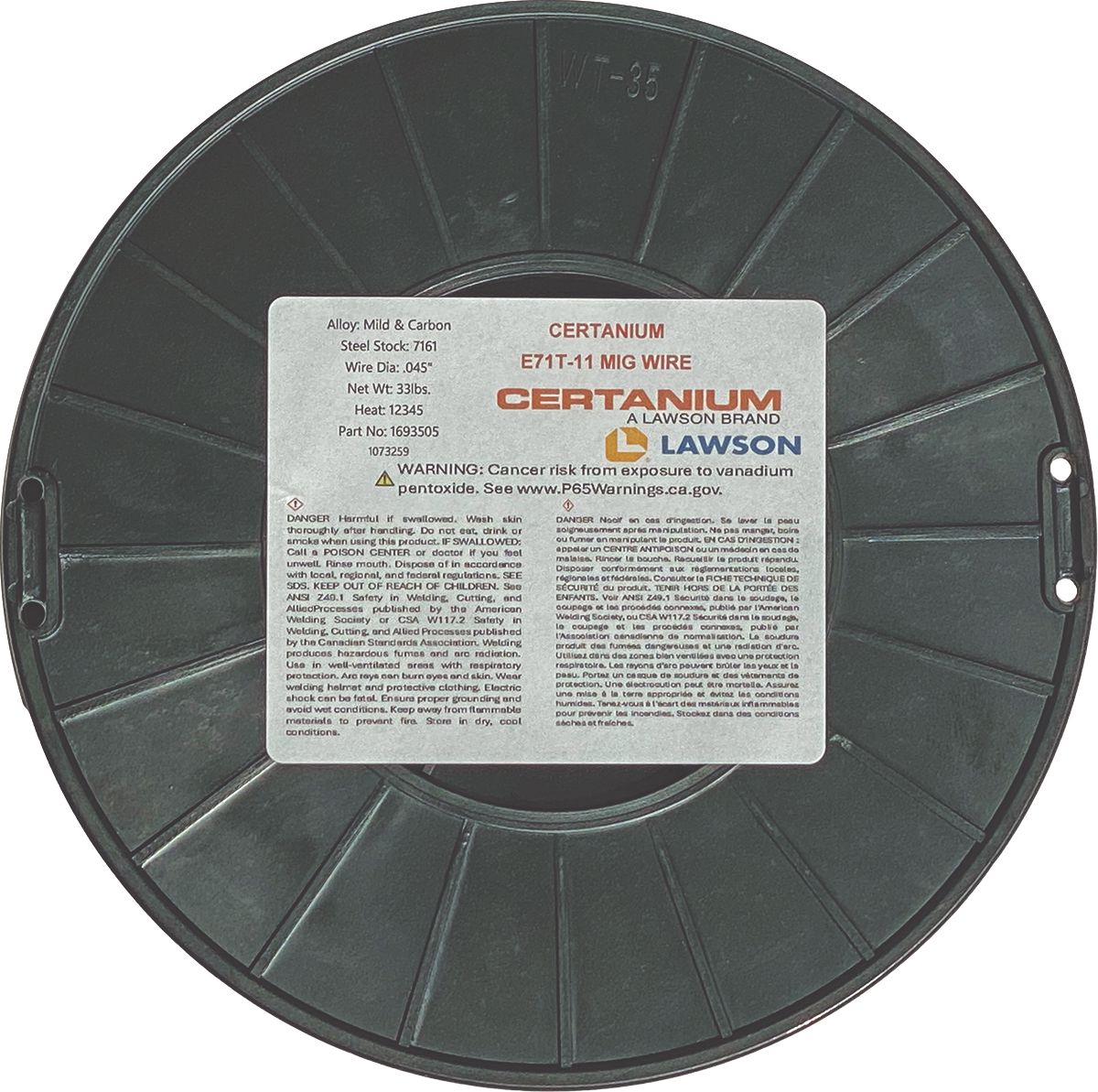

AWS E71T-11 Carbon Steel MIG Flux Core Welding Wire .045" 33lb

Couldn't load pickup availability

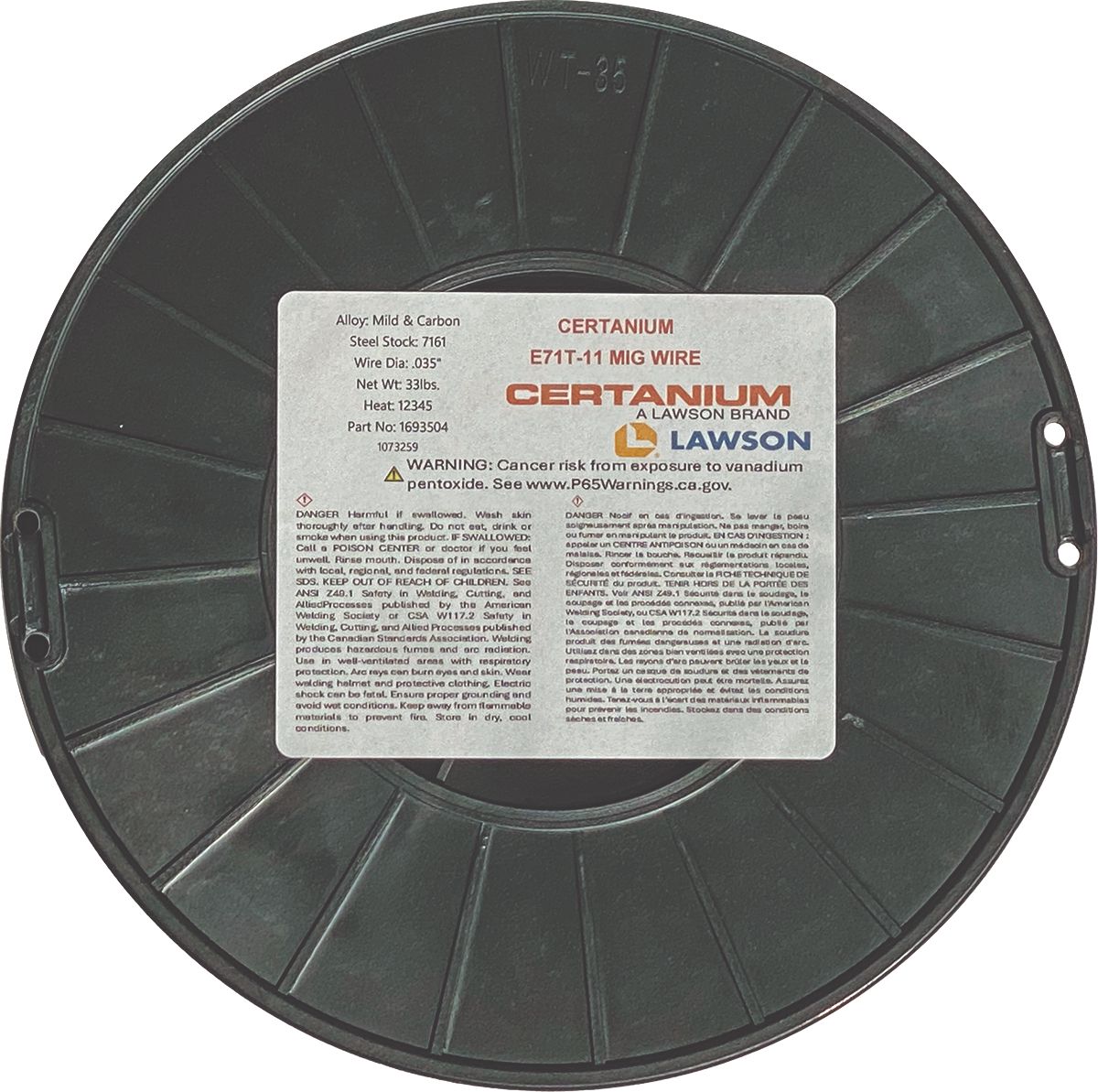

AWS E71T-11 Carbon Steel MIG Flux Core Welding Wire .035" 33lb

Couldn't load pickup availability

AWS E71T-11 Carbon Steel MIG Flux Core Welding Wire .062" 33lb

Couldn't load pickup availability

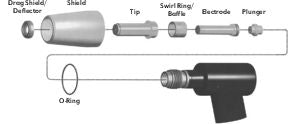

9-6003 Plasma Cutting Shield Cup

Couldn't load pickup availability

9-6507 Plasma Cutting Gas Distributor

Couldn't load pickup availability

21008 Plasma Cutting Tip

Couldn't load pickup availability

Product Description

Specially formulated for welding P-mold steels and most chrome-moly alloy steels.Superior Advantages

• Crack-resistant

• Premium operability

• High wear resistance

Tensile Strength: 89,700 PSIYield Strength: 73,400 PSIElongation: 26%Hardness: Rc 33-36Polarity: DC StraightGas: 100% Ar

Typical Applications

• Die-casting dies

• Injection molds

• Compression molding of plastics and chrome-moly steels like AISI 4130, 4140, 8620 and 8640

Usage ProcedureMaintain a short arc with minimal weave. Preheat as prescribed by base metal.

Technical Specifications

| Item#: | CW1986 |

|---|---|

| Welding Process | TIG |

| Type | Solid |

| Diameter | .035 " |

| Length | 36 " |

| Tensile Strength | 89,700 PSI |

| Yield Strength | 73,400 PSI |

| Elongation | 26 % |

| Base Metal | Tool Steel |

| Hardness | 33-36 HRC |

| Shielding Gas | 100% Ar |

| Polarity | DCSP |

| Quantity Per Package | 1.0000 |

| UNSPSC #: | 23271810 |

| TAA Compliant: | No |

| Weight: | 1.5 lb |

Product Restrictions

California Proposition 65: WARNING: Cancer -

www.P65Warnings.ca.gov