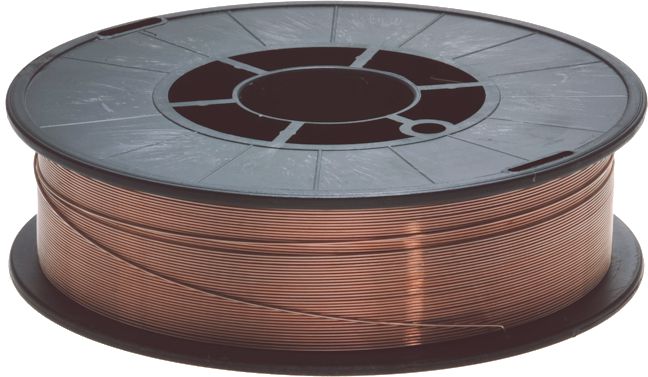

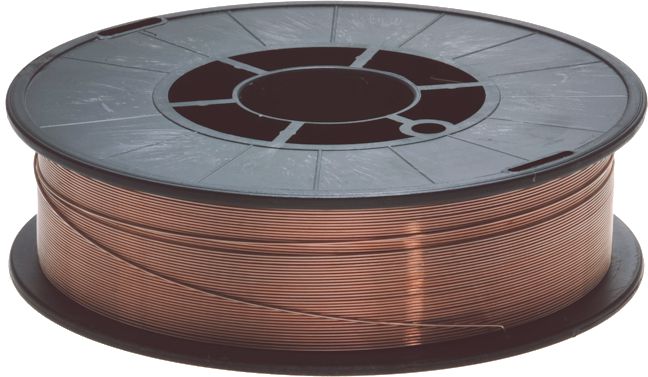

3880 Stainless Steel MIG Welding Wire 0.024"

(Pack of

2)

Get unmatched precision and durability with the 3880 Stainless Steel MIG Welding Wire. Engineered to deliver X-ray quality welds, it ensures smooth operation in all positions, making it ideal for joining the most common grades of stainless steel, including 303, 304, 308, and their low-carbon “L” versions. This wire minimizes carbide precipitation, providing excellent resistance to corrosion and heat, while its all-position capability reduces downtime by eliminating the need to dismantle equipment. Whether you're working on pipework, plate fabrication, or vessel production, the 3880 guarantees superior performance, easy slag removal, and increased efficiency for industrial welders and fabricators.

• Minimal carbide precipitation

• Excellent resistance to corrosion and heat

• All-position welding reduces the need to dismantle equipment

• Easy slag removal saves time

Tensile Strength: 85,000 PSIElongation: Up to 42%Gas: 98% Ar, 2% O2 or 90% He, 7.5% Ar, 2.5% CO2

Typical Applications

• Piping and tubing

• Food and medical processing equipment

• Housings and impellers

• Tanks and vats

Couldn't load pickup availability

California Proposition 65: WARNING: Cancer -

www.P65Warnings.ca.gov

Frequently Bought Together

Cross-Over Socket Extension Set, 3/8" Drive, 3 Piece

Couldn't load pickup availability

Autobahn Ergo Magna EZ Crimper Ratcheting Terminal Crimper

Couldn't load pickup availability

Anti-Rattle/Squeak BRS Tape 8 x 10"

Couldn't load pickup availability

Rear Bumper Cover Retainer Plastic 18mm

Couldn't load pickup availability

Bumper and Wheel Well Liner Push-Type Retainer

Couldn't load pickup availability

Acrysol Paint Preparation and Auto Body Solvent

Couldn't load pickup availability

184T High Nickel Molybendum Multi-Purpose Super Alloy Stick Electrode

Couldn't load pickup availability

E316L-16 Stainless Steel Stick Rod Electrode 1/8"

Couldn't load pickup availability

383 Stainless Steel TIG Wire 3/32"

Couldn't load pickup availability

ER70S-6 Mild/Carbon Steel MIG Welding Wire 0.03"

Couldn't load pickup availability

ER70S-6 Mild/Carbon Steel MIG Welding Wire 0.023"

Couldn't load pickup availability

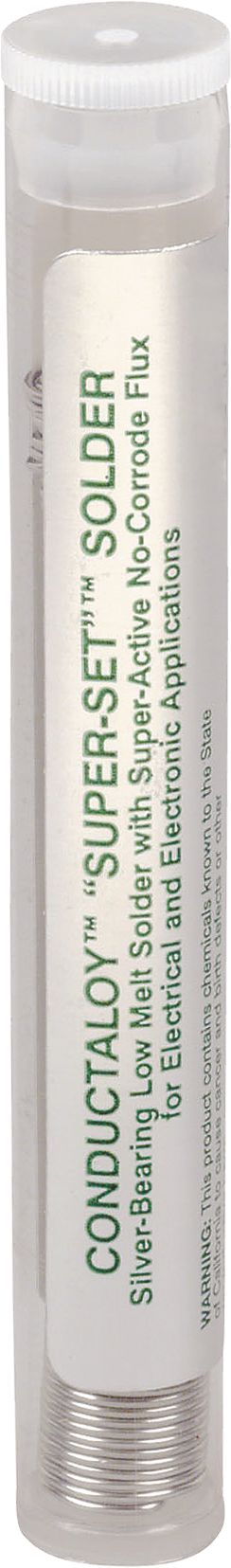

Solid Solder 1/32"

Couldn't load pickup availability

ER70S-6 Mild/Carbon Steel MIG Welding Wire 0.023"

Couldn't load pickup availability

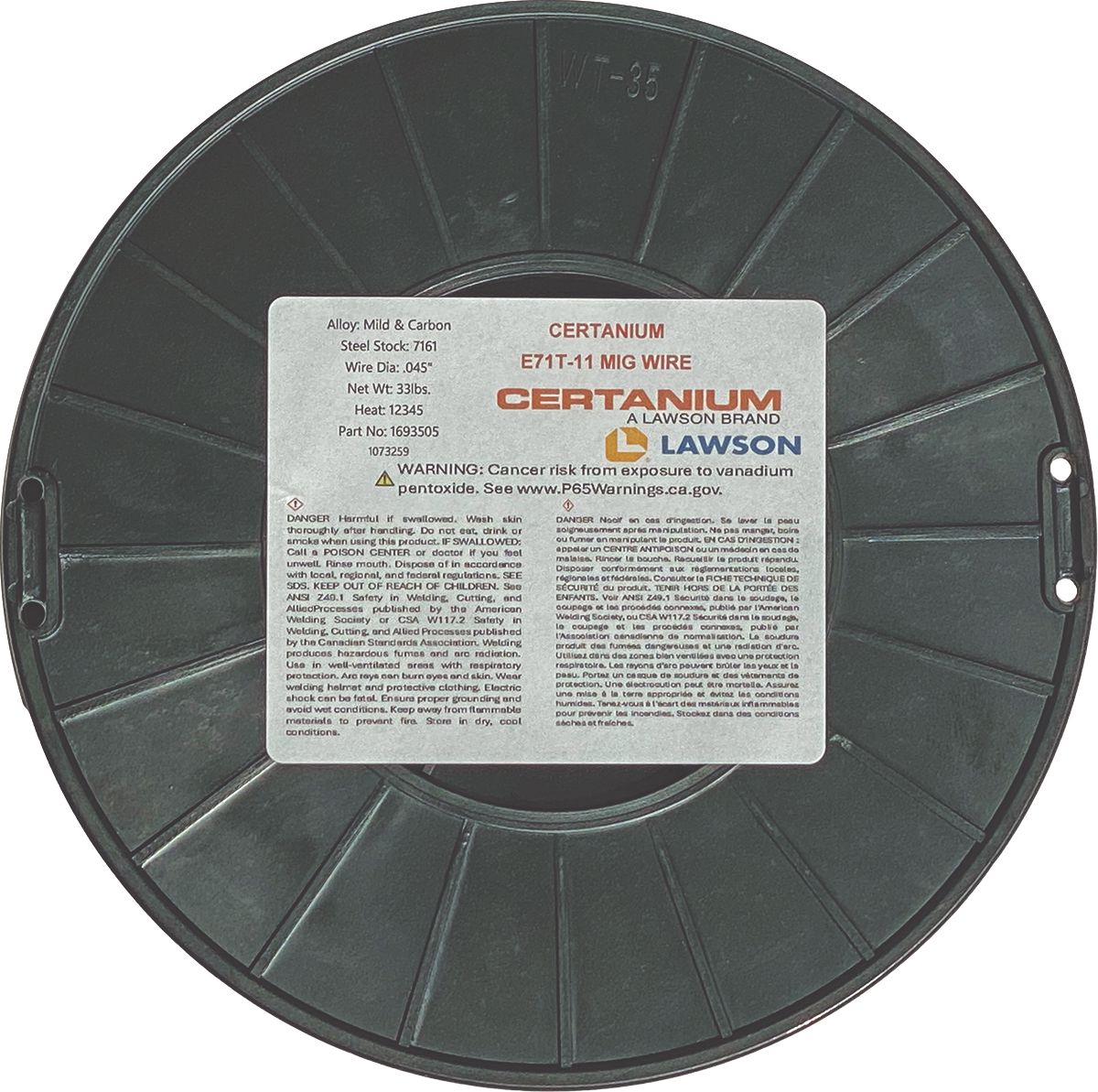

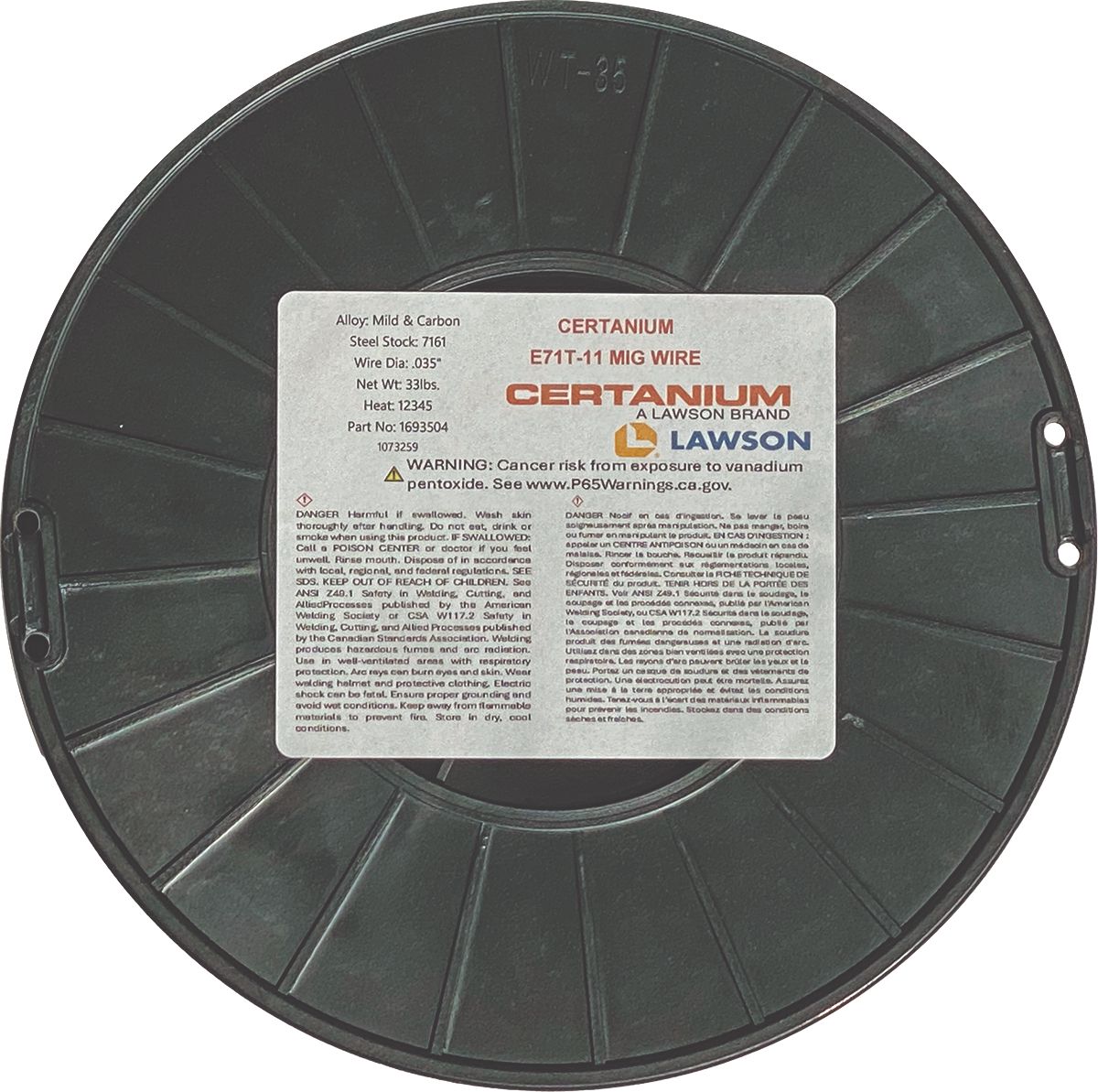

AWS E71T-11 Carbon Steel MIG Flux Core Welding Wire .045" 33lb

Couldn't load pickup availability

AWS E71T-11 Carbon Steel MIG Flux Core Welding Wire .035" 33lb

Couldn't load pickup availability

Product Description

Get unmatched precision and durability with the 3880 Stainless Steel MIG Welding Wire. Engineered to deliver X-ray quality welds, it ensures smooth operation in all positions, making it ideal for joining the most common grades of stainless steel, including 303, 304, 308, and their low-carbon “L” versions. This wire minimizes carbide precipitation, providing excellent resistance to corrosion and heat, while its all-position capability reduces downtime by eliminating the need to dismantle equipment. Whether you're working on pipework, plate fabrication, or vessel production, the 3880 guarantees superior performance, easy slag removal, and increased efficiency for industrial welders and fabricators.• Minimal carbide precipitation

• Excellent resistance to corrosion and heat

• All-position welding reduces the need to dismantle equipment

• Easy slag removal saves time

Tensile Strength: 85,000 PSIElongation: Up to 42%Gas: 98% Ar, 2% O2 or 90% He, 7.5% Ar, 2.5% CO2

Typical Applications

• Piping and tubing

• Food and medical processing equipment

• Housings and impellers

• Tanks and vats

Technical Specifications

| Item#: | CW1795 |

|---|---|

| Welding Process | MIG |

| Type | Solid |

| Diameter | .024 " |

| Tensile Strength | 85,000 PSI |

| Elongation | 42 % |

| Base Metal | Stainless Steel |

| Shielding Gas | 98Ar/2Ox |

| Polarity | DCRP |

| UNSPSC #: | 23271810 |

| TAA Compliant: | No |

| Weight: | 2.23 lb |

Product Restrictions

California Proposition 65: WARNING: Cancer -

www.P65Warnings.ca.gov