676 Flux Corred Wire Optional Sheilding Gas 100% Co2 Up 64Rc In Hardness For Carbon And Low Alloy And Manganese Steels

(Pack of

33)

A specially formulated flux cored wire designed to produce extremely wear-resistant deposits. The high concentration of small primary carbides greatly improves toughness and abrasion resistance over conventional chromium carbide alloys. Can be applied to carbon, low alloy, and manganese steels and can be used in hot wear applications up to 900°F/482°C.

• Smooth arc for superior control

• No gas required

• Deposit cross-checks readily

• Resists hot wear up to 900°F/482°C

• Hardness: Up to 64Rc

• Max Number of Passes: 2

• Impact Resistance: Moderate

• Machinability: Grind only

• Magnetic: – On Carbon Steel: Slightly – On Manganese Steel: No

• Hot Wear Applications: Up to 900°F/482°C

• Current: DCEP (DC+)

• Shielding Gas: Optional, 100% CO2

Frequently Bought Together

281 Martensitic Stick Rod Electrode 1/8"

Couldn't load pickup availability

670 Fc Build Up Flux Core For Carbon And Low Alloy Steels 1/16X33LB

Couldn't load pickup availability

7350 Carbide Hard Facing Stick Rod Electrode 1/4"

Couldn't load pickup availability

176 Extreme Abrasion With Impact 3/8X18IN

Couldn't load pickup availability

174 Gray High Abrasion Moderate Impact 3/16

Couldn't load pickup availability

H4 Carbide Hard Facing MIG Welding Wire 0.045"

Couldn't load pickup availability

Shield Push-Type Retainer with Metal Insert

Couldn't load pickup availability

Front Fender Push-Type Retainer Nylon 20mm

Couldn't load pickup availability

Rocker Panel Molding Clip Nylon White 12 x 20mm

Couldn't load pickup availability

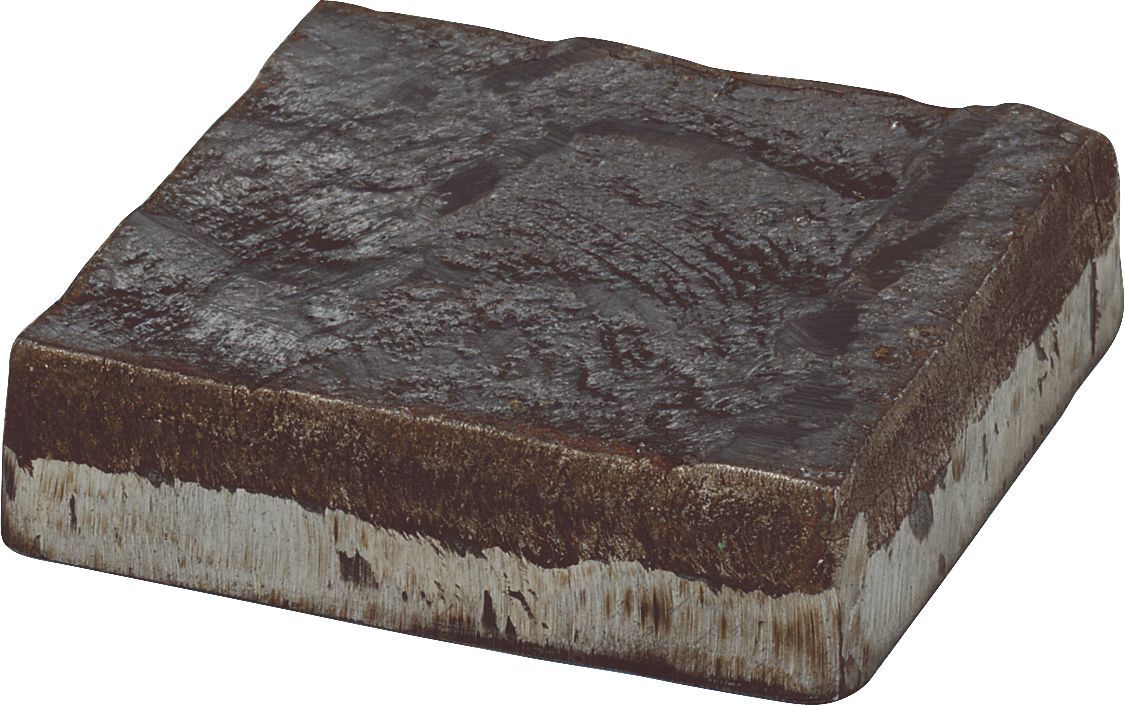

3/8 on 3/8 Dimension I Double Pass Overlay

Couldn't load pickup availability

Industrial Graphite Rod 1 x 12"

Couldn't load pickup availability

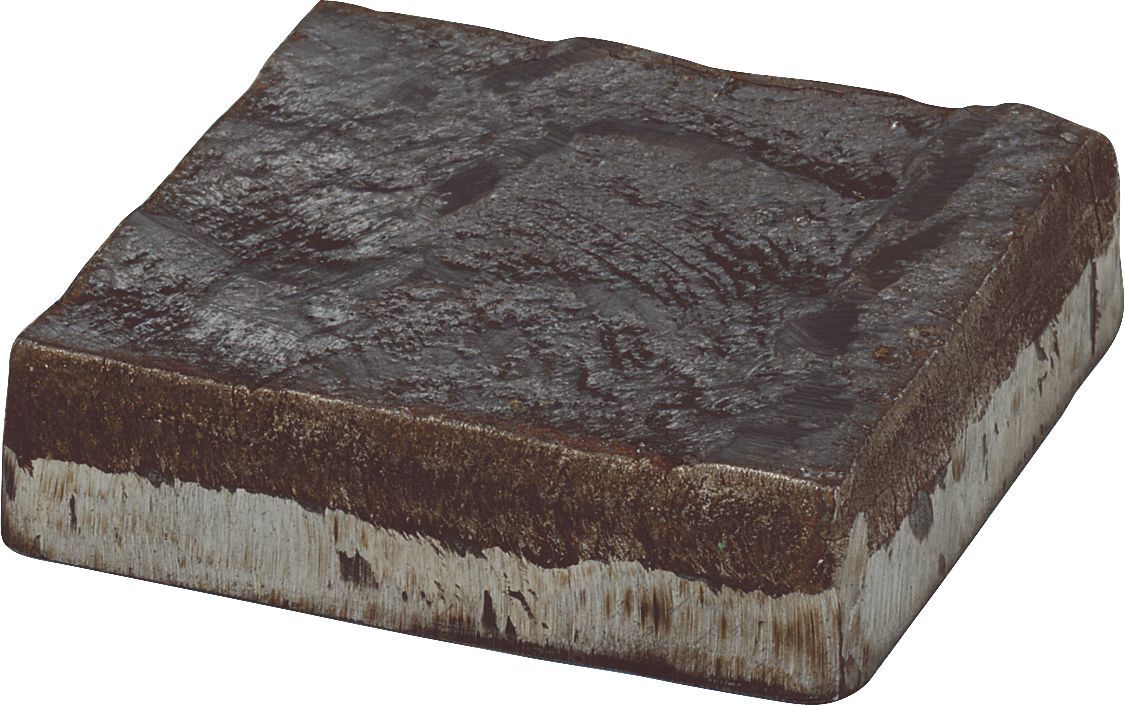

1/4 on 1/4 Dimension I Double Pass Overlay

Couldn't load pickup availability

Product Description

A specially formulated flux cored wire designed to produce extremely wear-resistant deposits. The high concentration of small primary carbides greatly improves toughness and abrasion resistance over conventional chromium carbide alloys. Can be applied to carbon, low alloy, and manganese steels and can be used in hot wear applications up to 900°F/482°C.• Smooth arc for superior control

• No gas required

• Deposit cross-checks readily

• Resists hot wear up to 900°F/482°C

• Hardness: Up to 64Rc

• Max Number of Passes: 2

• Impact Resistance: Moderate

• Machinability: Grind only

• Magnetic: – On Carbon Steel: Slightly – On Manganese Steel: No

• Hot Wear Applications: Up to 900°F/482°C

• Current: DCEP (DC+)

• Shielding Gas: Optional, 100% CO2

Technical Specifications

| Item#: | EG67680062 |

|---|---|

| Welding Process | Flux-Core Arc Welding |

| Type | Flux-Cored Wire |

| Diameter | 1/16 " |

| Base Metal | Carbon And Alloy Steels |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 37.62 lb |