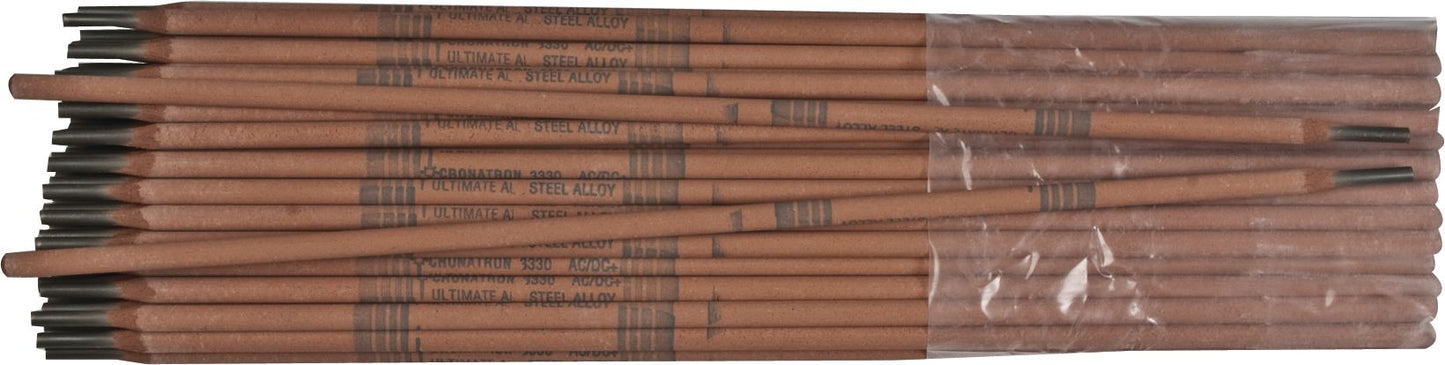

3330 Dissimilar Steel Stick Rod Electrode 5/32"

(Pack of

5.0)

The 3330 Dissimilar Steel Stick Rod Electrode is your go-to solution for challenging welds that demand precision and reliability. Specially engineered for joining different types of weldable steels, it delivers high-strength welds with exceptional resistance to cracking, even in demanding positions like vertical-up or overhead. Ideal for automotive repairs, welding rotors and blades, and joining pump and cast steel housings, this steel joining wire ensures superior performance in maintenance and repair operations. When durability and versatility are essential, the 3330 Electrode never lets you down.

• Tensile Strength: 127,000

• PSIElongation: 37%

• Hardness: 235

• BHNPolarity: AC or DC Reverse

Exceptional out-of-position welding

Usage ProcedureUse AC or DC reverse polarity. Electrode may be used in a contact “drag” fashion or by holding a short arc. Stringer beads or a slight weave is best. Remove slag between passes. When welding alloyed or tool steel, preheat according to base metal requirements. For vertical-up welding, use a 1/8" electrode at approximately 65 to 70 amps or a 5/32" electrode at 75 to 85 amps. Use a weave “ledge” technique, pausing momentarily at end of weaves.

Frequently Bought Together

333 Dissimilar Steel TIG Wire 1/16"

Couldn't load pickup availability

Dissimilar Steel Stick Rod Electrode Kit

Couldn't load pickup availability

X-Tractalloy Extracting Welding Electrode Non-Conductive Flux 1/8

Couldn't load pickup availability

Inner Panel Rustproofer LV 16.5oz

Couldn't load pickup availability

34 Oz Manual Sprayer

Couldn't load pickup availability

Round Turbo Mixer 18 Element with Integrated Nut

Couldn't load pickup availability

Cowl Bumper Fender Liner/Engine Under Cover Rivet

Couldn't load pickup availability

Bumper Radiator and Grille Drive Rivet 7mm Hole

Couldn't load pickup availability

Wheel House Molding Split Rivet Aluminum 3/16"

Couldn't load pickup availability

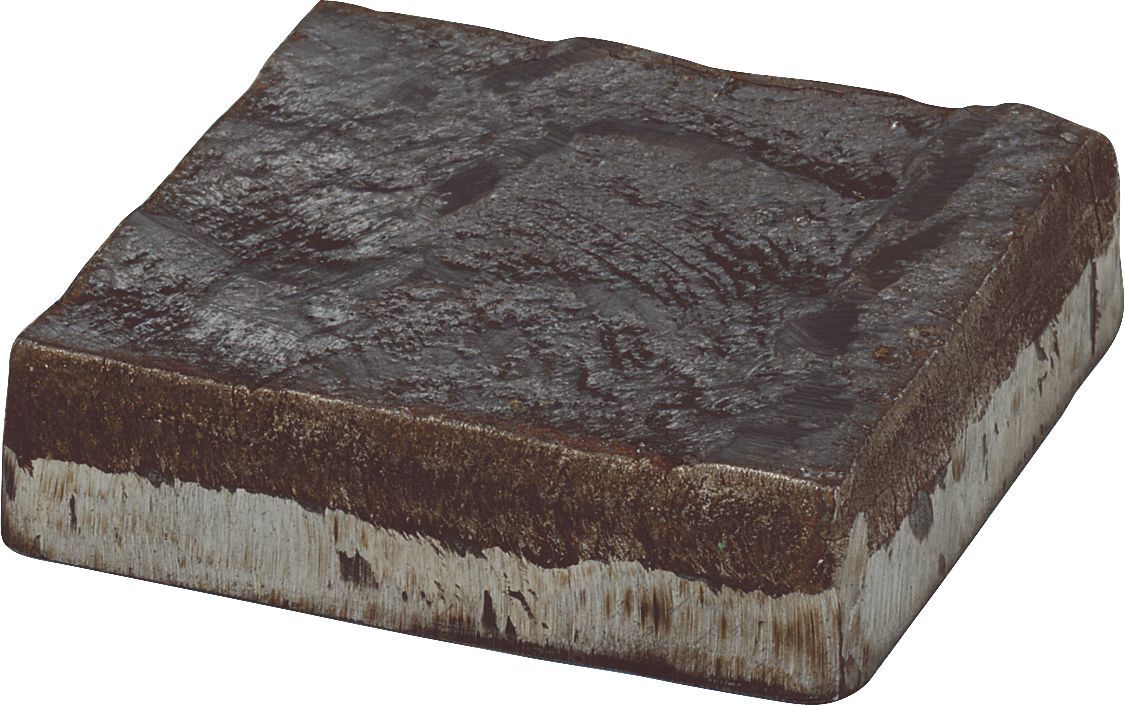

1/4 on 1/4 Dimension I Double Pass Overlay

Couldn't load pickup availability

3/16 on 3/16 Dimension I Single Pass Overlay

Couldn't load pickup availability

201 Rectangular Wear Disc Plate Kit

Couldn't load pickup availability

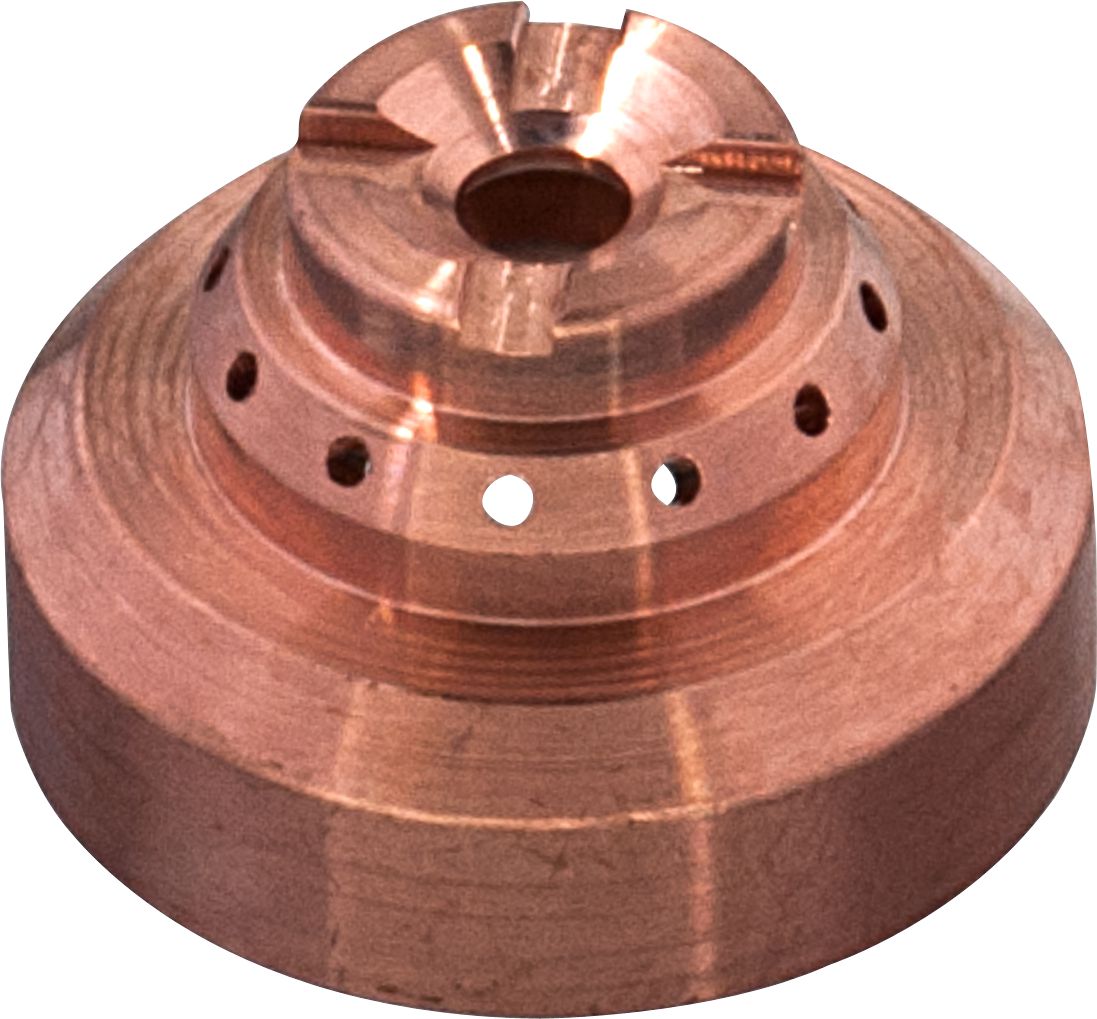

8-7500 Plasma Cutting Shield Cup

Couldn't load pickup availability

Oxy-Therm Striker Plate

Couldn't load pickup availability

192053 Plasma Cutting Drag Shield

Couldn't load pickup availability

Product Description

The 3330 Dissimilar Steel Stick Rod Electrode is your go-to solution for challenging welds that demand precision and reliability. Specially engineered for joining different types of weldable steels, it delivers high-strength welds with exceptional resistance to cracking, even in demanding positions like vertical-up or overhead. Ideal for automotive repairs, welding rotors and blades, and joining pump and cast steel housings, this steel joining wire ensures superior performance in maintenance and repair operations. When durability and versatility are essential, the 3330 Electrode never lets you down.• Tensile Strength: 127,000

• PSIElongation: 37%

• Hardness: 235

• BHNPolarity: AC or DC Reverse

Exceptional out-of-position welding

Usage ProcedureUse AC or DC reverse polarity. Electrode may be used in a contact “drag” fashion or by holding a short arc. Stringer beads or a slight weave is best. Remove slag between passes. When welding alloyed or tool steel, preheat according to base metal requirements. For vertical-up welding, use a 1/8" electrode at approximately 65 to 70 amps or a 5/32" electrode at 75 to 85 amps. Use a weave “ledge” technique, pausing momentarily at end of weaves.

Technical Specifications

| Item#: | CW1872 |

|---|---|

| Welding Process | Stick |

| Type | Flux Coated |

| Diameter | 5/32 " |

| Tensile Strength | 125,000 PSI |

| Yield Strength | 100,000 PSI |

| Elongation | 35 % |

| Polarity | DCRP/AC |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 5.0 lb |

Product Restrictions