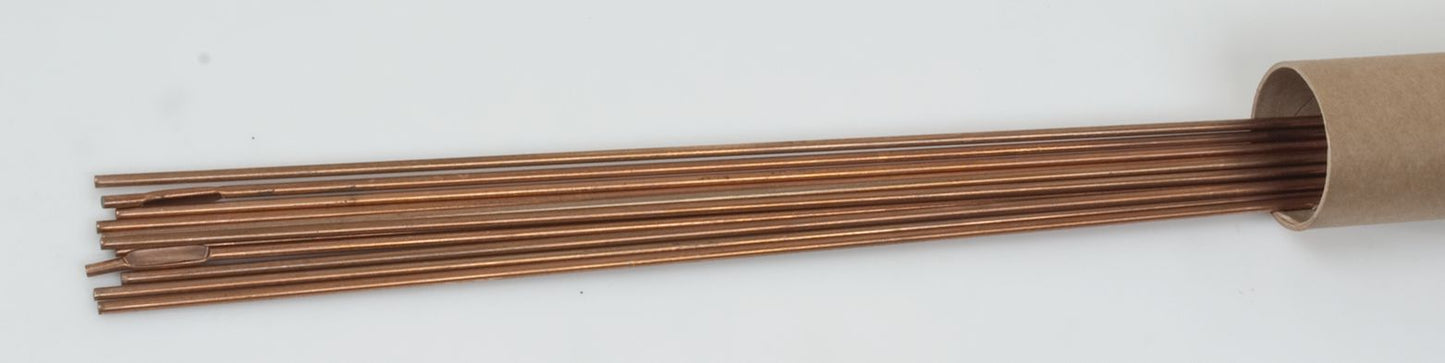

345 Tool Steel TIG Wire, Solid, 54 to 58 HRC Hardness, 100% Ar Shielding Gas, DCSP Polarity, 36" Length, 5/32"

(Pack of

2)

A broad selection of premium alloys to use for nearly any tool steel application and repair.

Superior Advantages

• Crack-resistant

• Premium operability

• High wear resistance

Hardness: Rc 54-58

Polarity: DC Straight

Gas: 100% Ar

Universal and “H” Series, Chromium Hot Work Tool SteelThe principal elements in this alloy are chromium, tungsten, moly and vanadium. This chemistry provides an extremely tough deposit with deep air-hardening capabilities up to 12". Types: H11, 12, 13, S1, S7, 01, 06.

Typical Applications

• Various tool steel repairs – specific alloy selection is dependent upon the type (or Series) of tool steel being repaired

• Forming dies, cutting tools and high impact tools

Frequently Bought Together

Ure-Foam Expandable Foam Sound Deadener 10fl.oz

Couldn't load pickup availability

Quick Seal 2000 Sprayable Seam Sealer Beige

Couldn't load pickup availability

Adhesive-Back Shim Stock 5/16 x 1" x 30'

Couldn't load pickup availability

Shield Push-Type Retainer with Metal Insert

Couldn't load pickup availability

Metric Indented Hex Head Bolt with 17mm Washer

Couldn't load pickup availability

Bumper Clip Push-Type Retainer Nylon 18mm

Couldn't load pickup availability

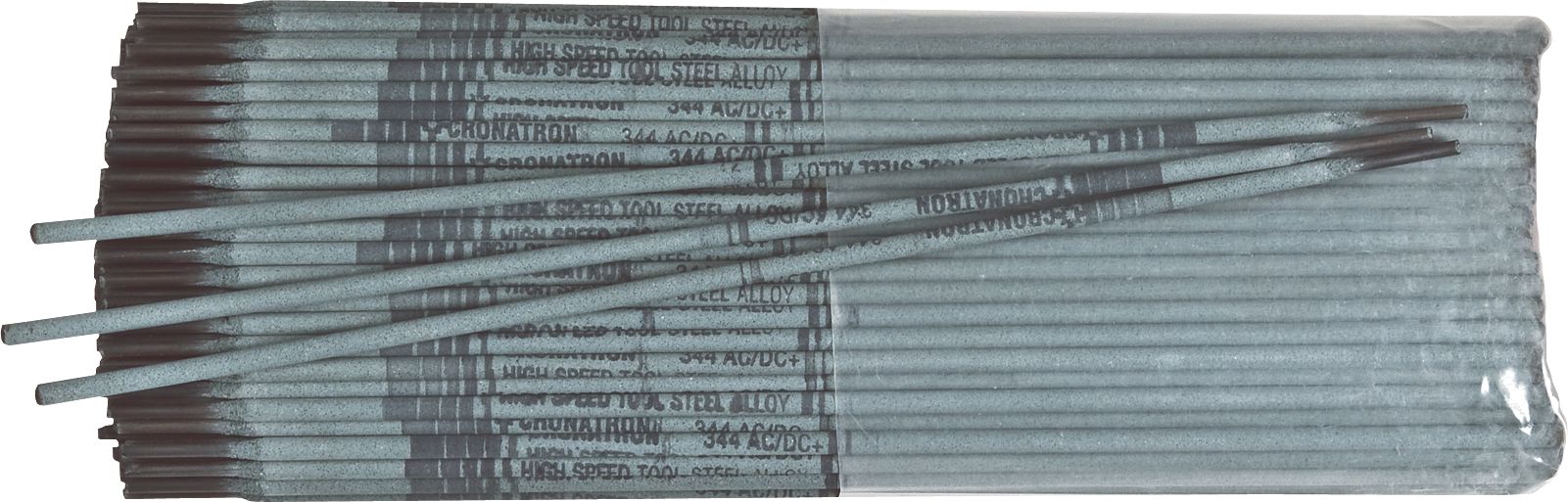

344 Tool Steel Stick Rod Electrode 1/8"

Couldn't load pickup availability

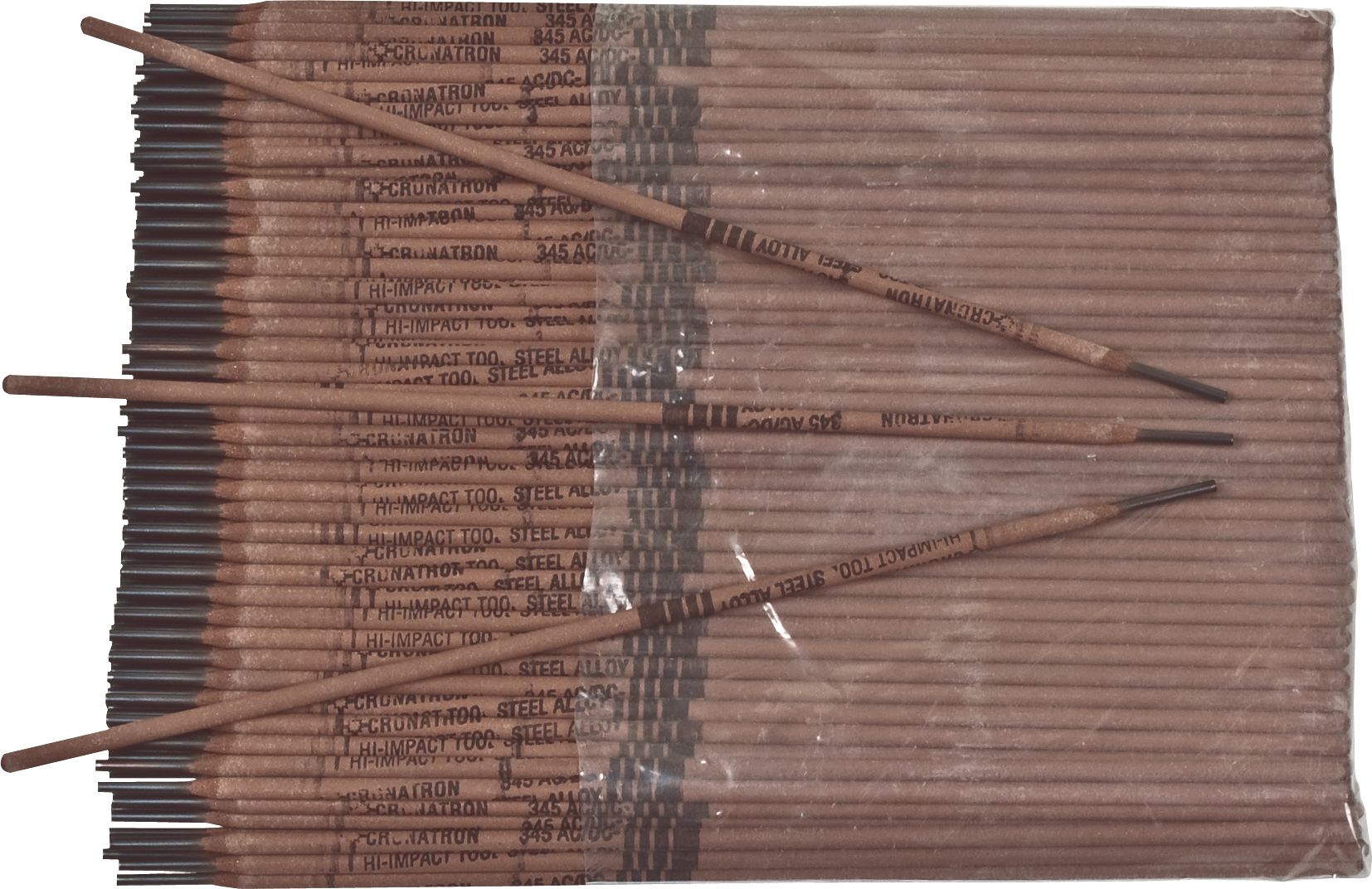

345 Tool Steel Stick Rod Electrode 3/32"

Couldn't load pickup availability

344 Tool Steel Stick Rod Electrode 3/32"

Couldn't load pickup availability

201 Rectangular Wear Disc Plate Kit

Couldn't load pickup availability

Industrial Graphite Block 2 x 10 x 12"

Couldn't load pickup availability

Wear Plates Used By Maintenance Welder

Couldn't load pickup availability

Oxy-Therm Collet 3/8"

Couldn't load pickup availability

Oxy-Therm Collet Grommet 1/4"

Couldn't load pickup availability

Oxy-Therm System

Couldn't load pickup availability

Product Description

A broad selection of premium alloys to use for nearly any tool steel application and repair.Superior Advantages

• Crack-resistant

• Premium operability

• High wear resistance

Hardness: Rc 54-58

Polarity: DC Straight

Gas: 100% Ar

Universal and “H” Series, Chromium Hot Work Tool SteelThe principal elements in this alloy are chromium, tungsten, moly and vanadium. This chemistry provides an extremely tough deposit with deep air-hardening capabilities up to 12". Types: H11, 12, 13, S1, S7, 01, 06.

Typical Applications

• Various tool steel repairs – specific alloy selection is dependent upon the type (or Series) of tool steel being repaired

• Forming dies, cutting tools and high impact tools

Technical Specifications

| Item#: | CW1891 |

|---|---|

| Welding Process | TIG |

| Type | Solid |

| Diameter | 5/32 " |

| Length | 36 " |

| Base Metal | Tool Steel |

| Hardness | 54-58 HRC |

| Shielding Gas | 100% Ar |

| Polarity | DCSP |

| Quantity Per Package | 2.0000 |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 2.5 lb |

Product Restrictions