184T High Nickel Molybendum Tig Wire 5/32X36

(Pack of

5)

A high-strength alloy with high-nickel and molybdenum content that gives outstanding corrosion and heat resistance. It is highly resistant to chloride pitting and stress corrosion cracking. Columbium alloy additions increase weld stability. Excellent for welding dissimilar nickel base alloys and nickel alloys to ferrous metals. It is also well suited for welding Inconel 625, 706, 718 and X-750; Incoloy 800 and 825; Monel alloy K-500; Hastelloy B, C or G, and Carpenter 20 Cb.

• Tensile Strength: 110,000 PSI/758 Mpa

• Hardness: 21 Rc

• Elevated Temperature Tensile Data: – 1000°F/538°C: 85,000 PSI/507 Mpa – 1800°F/982°C: 25,000 PSI/173 Mpa

• Elongation: 30%

• Current: DCEN (DC-)

• Gas: 100% Argon

• Sulfuric Acid – Good up to 150°F/66°C for all concentrations, also good up to the boiling point for all concentrations below 10%

• Hydrochloric Acid – Very good up to 120°F/49°C for all concentrations

• Nitric Acid – Excellent corrosion resistance at almost all temperatures and concentrations

• Phosphoric Acid – Excellent at temperatures below 225°F/143°C for all concentrations

• Good above 225°F/143°C, except near the boiling point in very high concentrations

• Organic Acids – Generally excellent at all temperatures and concentrations

• Sodium Hydroxide (Caustic) – Generally excellent at all temperatures and concentrations

Frequently Bought Together

Nylon Cable Tie 7-1/2" Black

Couldn't load pickup availability

Bumper Cover Push-Type Retainer Nylon 18mm

Couldn't load pickup availability

Fender Splash Shield Retainer Nylon 20mm

Couldn't load pickup availability

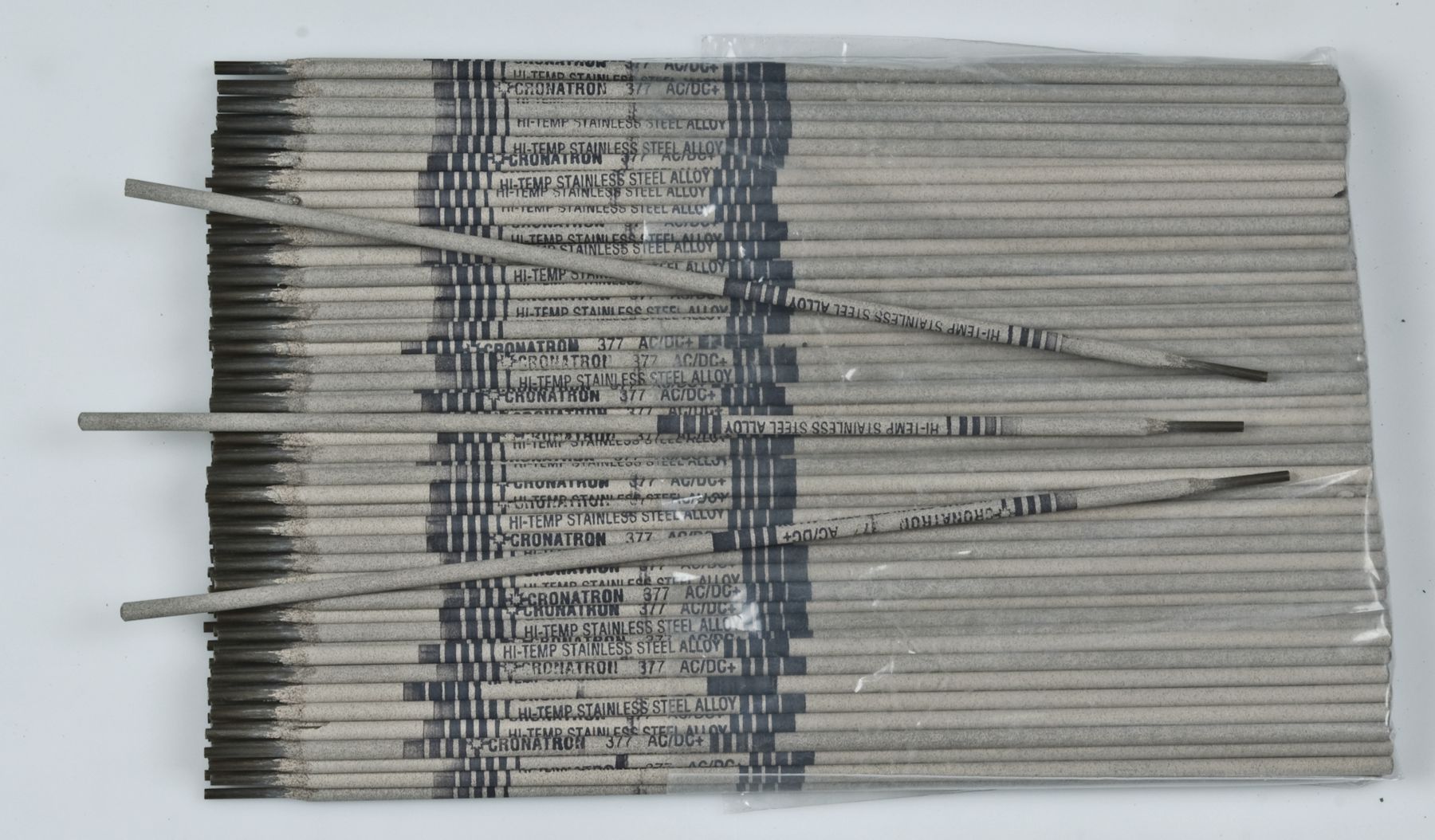

377 Stainless Steel Stick Rod Electrode 3/32"

Couldn't load pickup availability

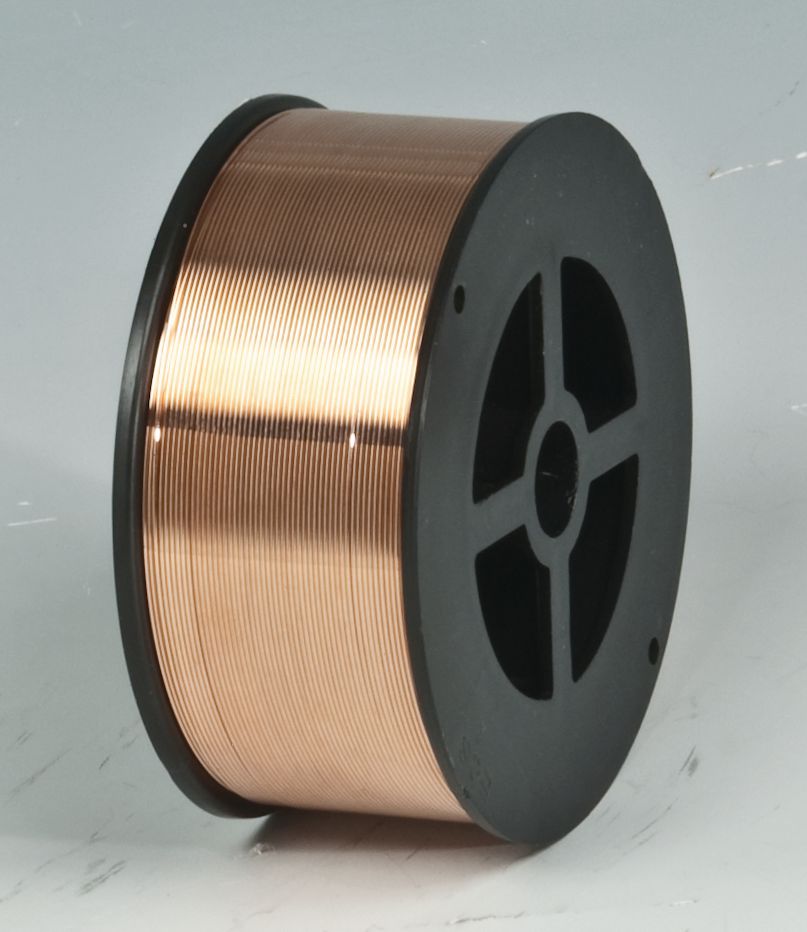

383 Stainless Steel MIG Welding Wire 0.035"

Couldn't load pickup availability

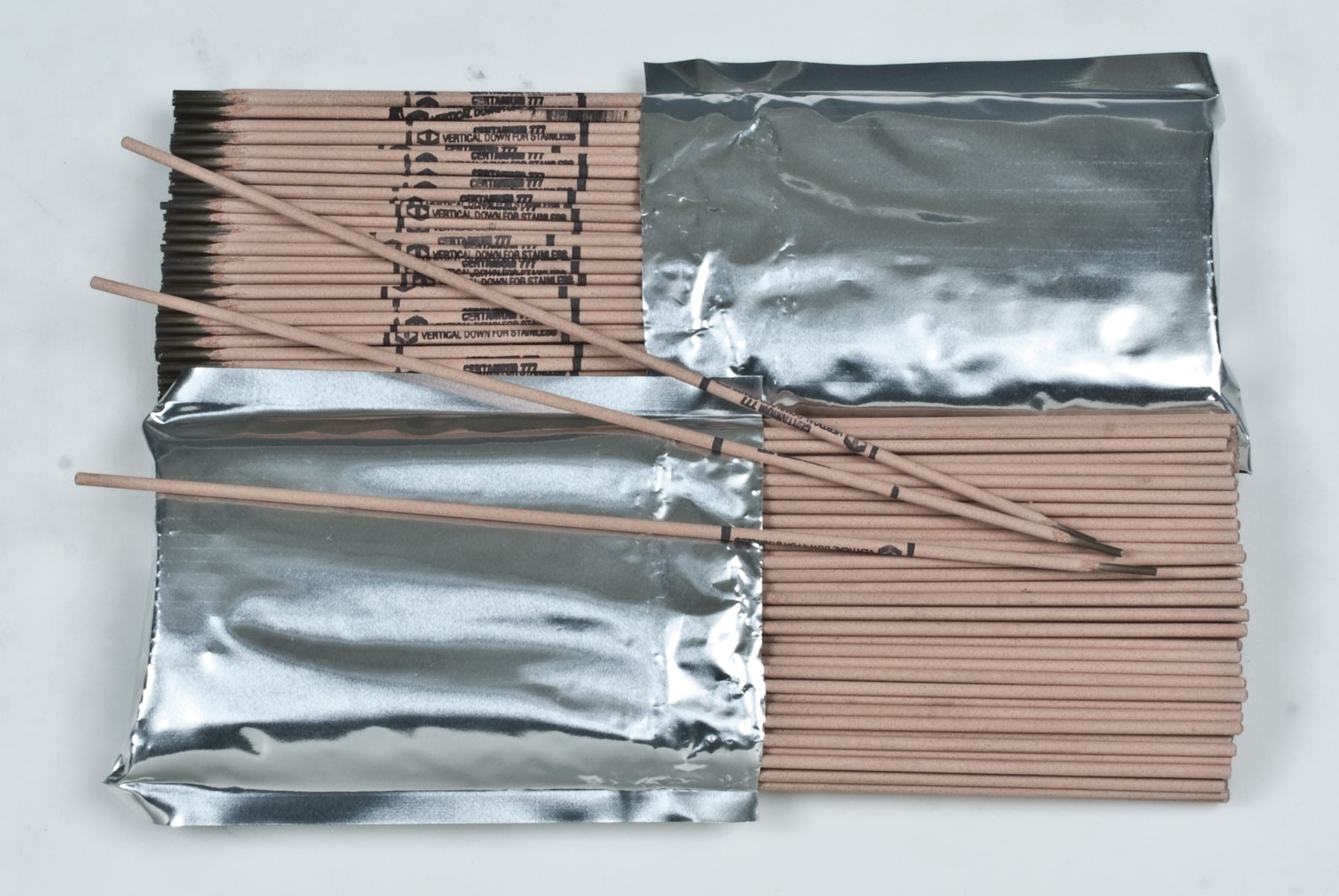

777 Stainless Steel Stick Rod Electrode 3/32"

Couldn't load pickup availability

Spring Loaded Trigger Torch Lighter

Couldn't load pickup availability

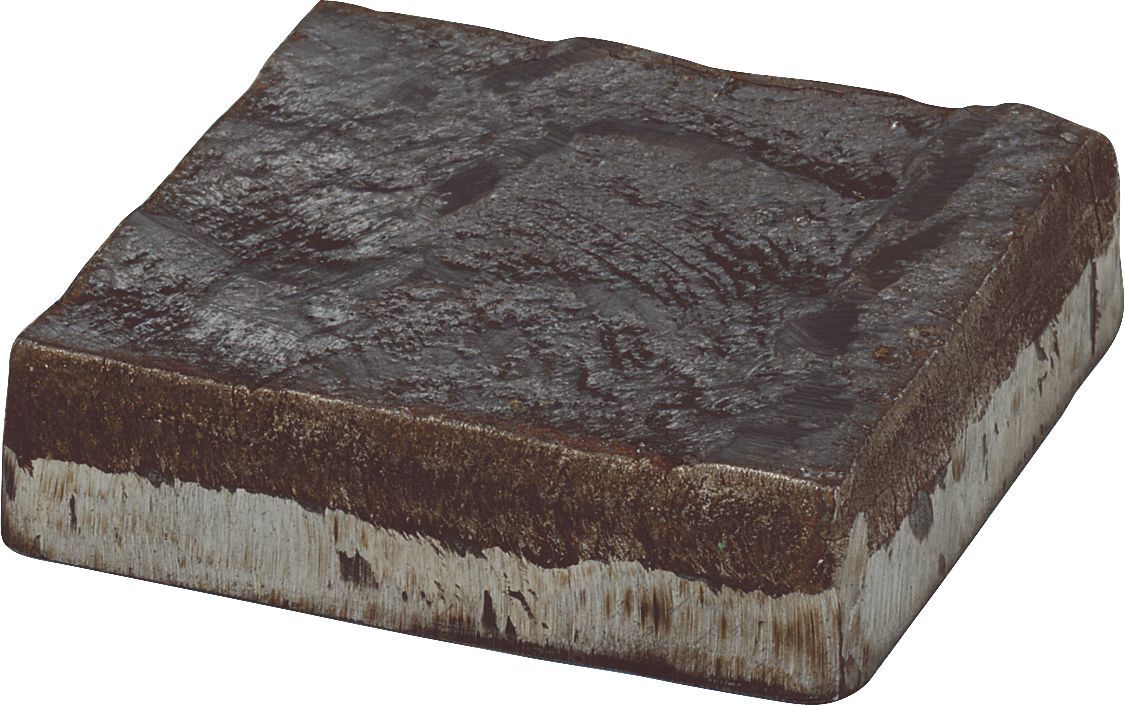

1/4 on 1/4 Dimension I Single Pass Overlay

Couldn't load pickup availability

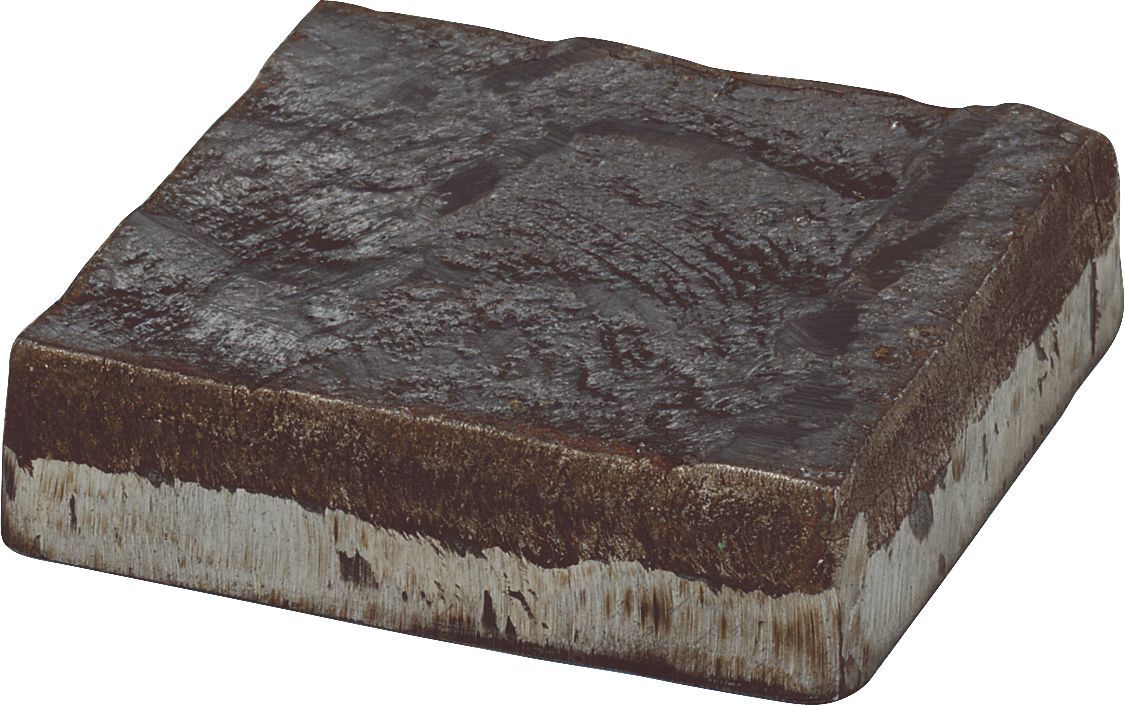

1/8 on 1/4 Dimension I Single Pass Overlay

Couldn't load pickup availability

331 Mild and Carbon Steel MIG Welding Wire 0.03"

Couldn't load pickup availability

321 Mild and Carbon Steel MIG Welding Wire 0.03"

Couldn't load pickup availability

E7024Mild /Carbon Steel Stick Electrode 3/16"

Couldn't load pickup availability

Product Description

A high-strength alloy with high-nickel and molybdenum content that gives outstanding corrosion and heat resistance. It is highly resistant to chloride pitting and stress corrosion cracking. Columbium alloy additions increase weld stability. Excellent for welding dissimilar nickel base alloys and nickel alloys to ferrous metals. It is also well suited for welding Inconel 625, 706, 718 and X-750; Incoloy 800 and 825; Monel alloy K-500; Hastelloy B, C or G, and Carpenter 20 Cb.• Tensile Strength: 110,000 PSI/758 Mpa

• Hardness: 21 Rc

• Elevated Temperature Tensile Data: – 1000°F/538°C: 85,000 PSI/507 Mpa – 1800°F/982°C: 25,000 PSI/173 Mpa

• Elongation: 30%

• Current: DCEN (DC-)

• Gas: 100% Argon

• Sulfuric Acid – Good up to 150°F/66°C for all concentrations, also good up to the boiling point for all concentrations below 10%

• Hydrochloric Acid – Very good up to 120°F/49°C for all concentrations

• Nitric Acid – Excellent corrosion resistance at almost all temperatures and concentrations

• Phosphoric Acid – Excellent at temperatures below 225°F/143°C for all concentrations

• Good above 225°F/143°C, except near the boiling point in very high concentrations

• Organic Acids – Generally excellent at all temperatures and concentrations

• Sodium Hydroxide (Caustic) – Generally excellent at all temperatures and concentrations

Technical Specifications

| Item#: | EG2003184T |

|---|---|

| Welding Process | TIG |

| Type | TIG |

| Diameter | 5/32 " |

| Length | 36 " |

| Tensile Strength | 110,000 PSI |

| Base Metal | Nickel Alloys; Dissimilar Metals |

| Hardness | 21 HRC |

| Shielding Gas | 100% Argon |

| Polarity | DCEN |

| UNSPSC #: | 23271810 |

| TAA Compliant: | No |

| Weight: | 5.96 lb |