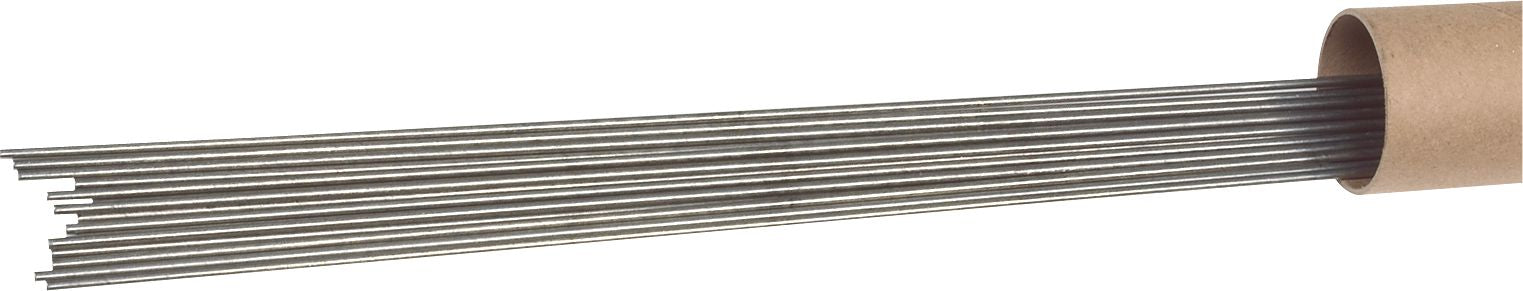

211 Cast Iron TIG Wire, Solid, 185 to 240 HB Hardness, 100% Ar Shielding Gas, DCSP Polarity, 36" Length, 1/16"

(Pack of

2)

SKU:CW1901 Item#: CW1901

All-position welding for any type of weldable cast iron repair and cast iron to steel.

Superior Advantages

• High strength welds

• Fully machinable

• Pass-over-pass welding to save time

• All-position welding may eliminate the need to dismantle equipment to perform repairs

Tensile Strength: Up to 60,000 PSIHardness: 185 – 240 BHNPolarity: DC StraightGas: 100% Ar

Soft, ductile (copper/nickel) TIG filler wire provides excellent elongation for crack sensitive cast iron repairs. Excellent machinability and sealing properties for repairs on cylinder heads, blocks and thin castings such as water jackets.

Typical Applications

• Pump and bearing housings

• Cylinder blocks and heads

• Machine bases

• Manifolds and exhaust systems

Usage ProcedureUse DC straight polarity. Stringer beads are recommended.

Couldn't load pickup availability

California Proposition 65: WARNING: Cancer -

www.P65Warnings.ca.gov

Frequently Bought Together

131 Cast-Weld Special Purpose Cast Iron Electrode 3/16

Couldn't load pickup availability

130 Hpm Cast Iron Machinable Electrode 5/32

Couldn't load pickup availability

133 Econo-Cast Wear Resistant Cast Electrode 5/32

Couldn't load pickup availability

Wheel Opening Drive Rivet Aluminum 5/32"

Couldn't load pickup availability

Rivet Nylon 1/4"

Couldn't load pickup availability

Miniature Incandescent Bulb 12V 2CP

Couldn't load pickup availability

Flat Soapstone 1/2"

Couldn't load pickup availability

Pipe Wrap Around

Couldn't load pickup availability

Anti Splatter Heat Resistant Welding Mat 2 x 3'

Couldn't load pickup availability

211 Cast Iron TIG Wire 1/8"

Couldn't load pickup availability

161 Arc Prep Metal Working Electrode 1/8

Couldn't load pickup availability

704 Mild/Carbon Steel Stick Rod Electrode 1/8"

Couldn't load pickup availability

Product Description

All-position welding for any type of weldable cast iron repair and cast iron to steel.Superior Advantages

• High strength welds

• Fully machinable

• Pass-over-pass welding to save time

• All-position welding may eliminate the need to dismantle equipment to perform repairs

Tensile Strength: Up to 60,000 PSIHardness: 185 – 240 BHNPolarity: DC StraightGas: 100% Ar

Soft, ductile (copper/nickel) TIG filler wire provides excellent elongation for crack sensitive cast iron repairs. Excellent machinability and sealing properties for repairs on cylinder heads, blocks and thin castings such as water jackets.

Typical Applications

• Pump and bearing housings

• Cylinder blocks and heads

• Machine bases

• Manifolds and exhaust systems

Usage ProcedureUse DC straight polarity. Stringer beads are recommended.

Technical Specifications

| Item#: | CW1901 |

|---|---|

| Welding Process | TIG |

| Type | Solid |

| Diameter | 1/16 " |

| Length | 36 " |

| Tensile Strength | 60,000 PSI |

| Base Metal | Cast Iron |

| Hardness | 185-240 BHN |

| Shielding Gas | 100% Ar |

| Polarity | DCSP |

| UNSPSC #: | 23271810 |

| TAA Compliant: | No |

| Weight: | 2.5 lb |

Product Restrictions

California Proposition 65: WARNING: Cancer -

www.P65Warnings.ca.gov