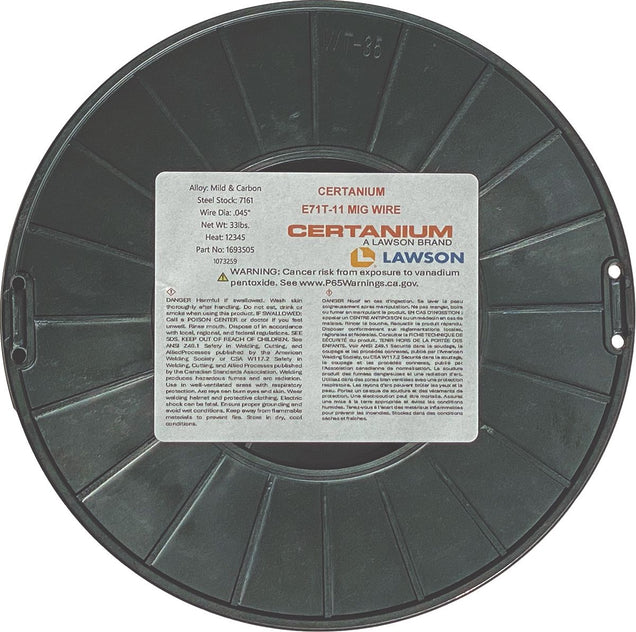

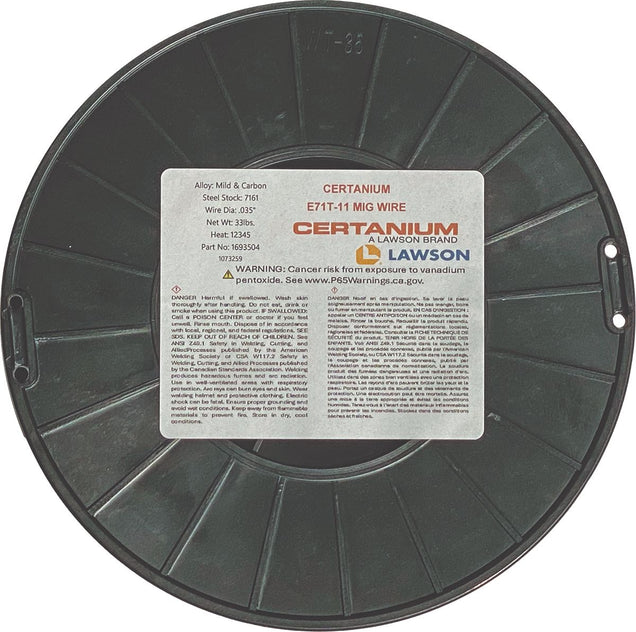

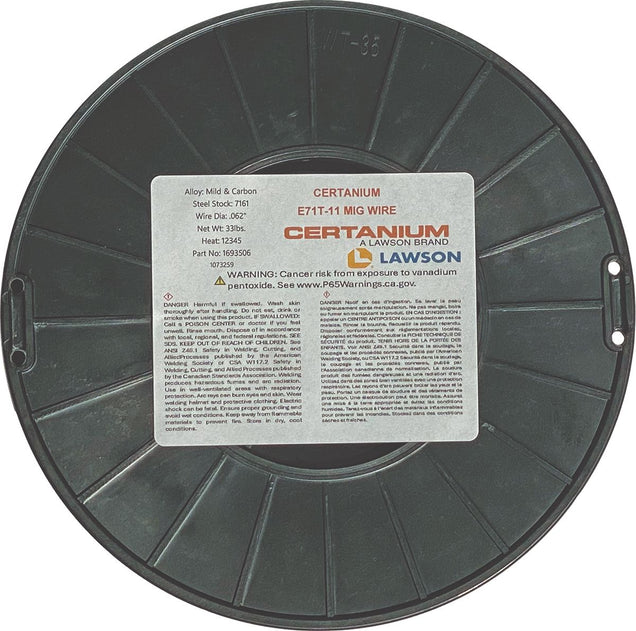

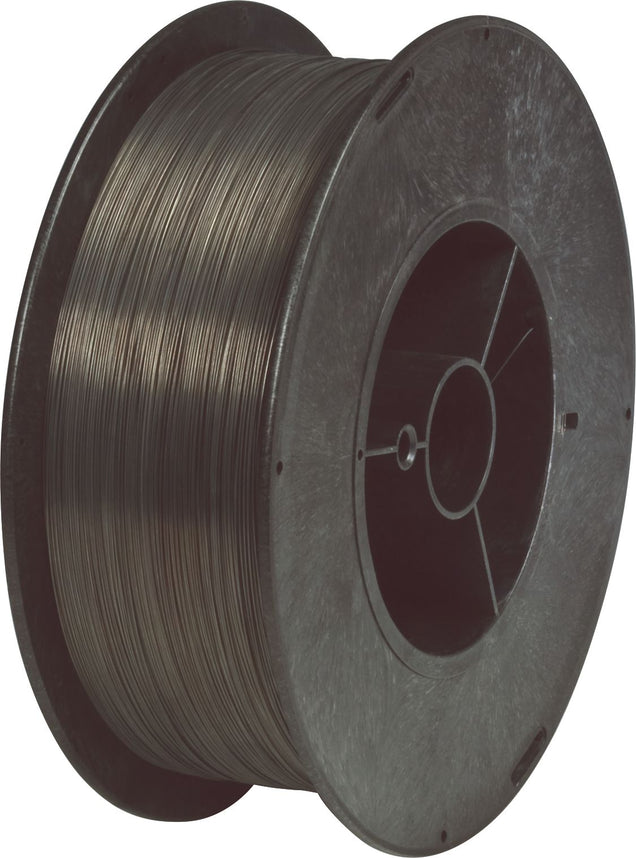

311 Mild and Carbon Steel MIG Welding Wire, Flux Cored, 75Ar/25CO2 Shielding Gas, 29% Elongation, DCRP Polarity, 0.045"

(Pack of

33)

SKU:CW1765 Item#: CW1765

Easy-to-use, all-position electrodes are fully machinable and designed to resist underbead cracking. For use in a variety of applications for everyday maintenance of mild and low-alloy steels.

Superior Advantages

• Fully machinable

• Resists cracking due to high elongation

• Easy slag removal saves time

• Moisture-resistant coating

• Meets or exceeds low-hydrogen requirements

Tensile Strength: 81,000 PSIYield Strength: 72,000 PSIElongation: 29%Gas: 75% Ar, 25% CO2

Typical Applications • Use on free-machining or high sulfur steels• Agriculture equipment• Structural members• Truck bodies and frames• Pipes, flanges, channels, tubes and shafts• Holding tanks, steel vessels

Couldn't load pickup availability

California Proposition 65: WARNING: Cancer -

www.P65Warnings.ca.gov

Frequently Bought Together

ER70S-6 Mild/Carbon Steel MIG Welding Wire 0.035"

Couldn't load pickup availability

1100 Gouging and Cutting Stick Rod Electrode 3/16"

Couldn't load pickup availability

163 Arc-Cut Synthetic Carbon Arc Electrode

Couldn't load pickup availability

Front Bumper and Radiator Support Drive Rivet

Couldn't load pickup availability

Metric Indented Hex Head Bolt with 17mm Washer

Couldn't load pickup availability

Hex Head Sheet Metal Screw with 16mm Washer Steel

Couldn't load pickup availability

Heat Stick 650F Degrees

Couldn't load pickup availability

Heat Stick 850F Degrees

Couldn't load pickup availability

Cap Whip-Lead Connector #4 to #1

Couldn't load pickup availability

Oxy-Therm Collet Grommet 1/4"

Couldn't load pickup availability

Oxy-Therm System

Couldn't load pickup availability

Oxy-Therm Collet 1/4"

Couldn't load pickup availability

Product Description

Easy-to-use, all-position electrodes are fully machinable and designed to resist underbead cracking. For use in a variety of applications for everyday maintenance of mild and low-alloy steels.Superior Advantages

• Fully machinable

• Resists cracking due to high elongation

• Easy slag removal saves time

• Moisture-resistant coating

• Meets or exceeds low-hydrogen requirements

Tensile Strength: 81,000 PSIYield Strength: 72,000 PSIElongation: 29%Gas: 75% Ar, 25% CO2

Typical Applications • Use on free-machining or high sulfur steels• Agriculture equipment• Structural members• Truck bodies and frames• Pipes, flanges, channels, tubes and shafts• Holding tanks, steel vessels

Technical Specifications

| Item#: | CW1765 |

|---|---|

| Welding Process | MIG |

| Type | Flux Cored |

| Diameter | .045 " |

| Tensile Strength | 81,000 PSI |

| Yield Strength | 72,000 PSI |

| Elongation | 29 % |

| Base Metal | Mild & Carbon Steel |

| Shielding Gas | 75Ar/25CO2 |

| Polarity | DCRP |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 33.0 lb |

Product Restrictions

California Proposition 65: WARNING: Cancer -

www.P65Warnings.ca.gov