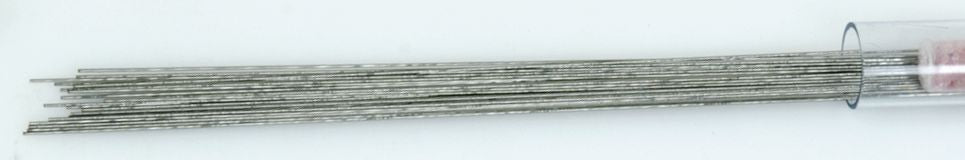

349 Tool Steel TIG Wire, Solid, 33 to 36 HRC Hardness, 100% Ar Shielding Gas, 26% Elongation, 18" Length, 0.02"

(Pack of

25)

Specially formulated for welding P-mold steels and most chrome-moly alloy steels.

Superior Advantages

• Crack-resistant

• Premium operability

• High wear resistance

Tensile Strength: 89,700 PSIYield Strength: 73,400 PSIElongation: 26%Hardness: Rc 33-36Polarity: DC StraightGas: 100% Ar

Typical Applications

• Die-casting dies

• Injection molds

• Compression molding of plastics and chrome-moly steels like AISI 4130, 4140, 8620 and 8640

Usage ProcedureMaintain a short arc with minimal weave. Preheat as prescribed by base metal.

Frequently Bought Together

Push-Type Retainer Nylon 20mm

Couldn't load pickup availability

Hex Head Sheet Metal Screw with 17mm Washer Steel

Couldn't load pickup availability

Nylon Cable Tie 7-1/2" Black

Couldn't load pickup availability

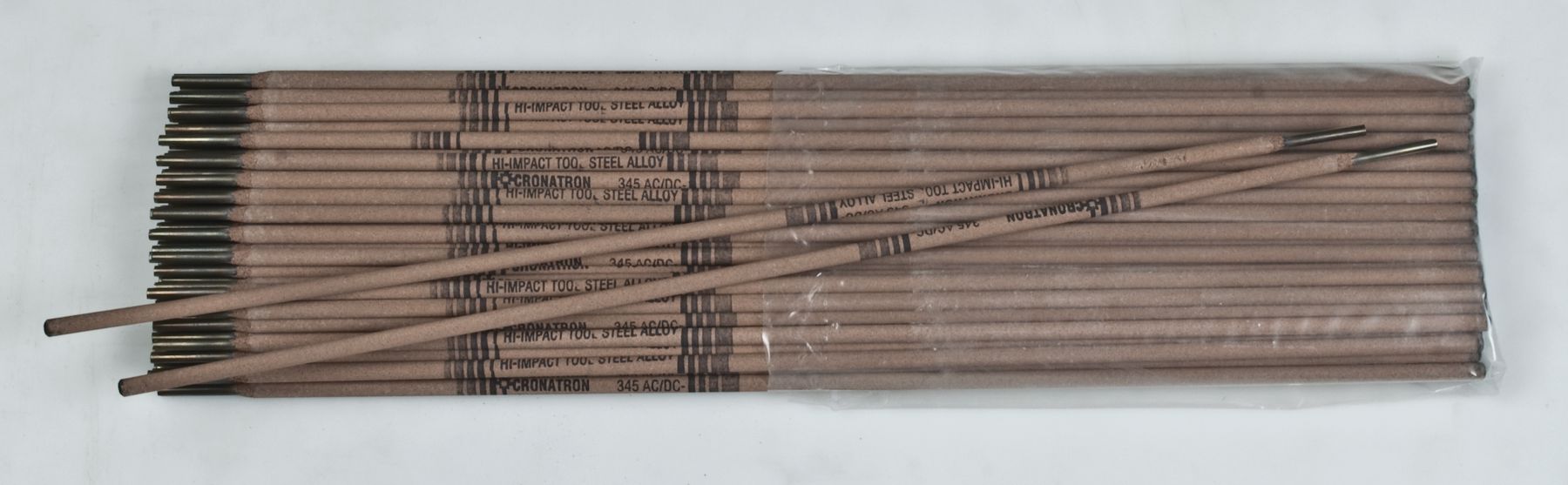

345 Tool Steel Stick Rod Electrode 1/8"

Couldn't load pickup availability

345 Tool Steel TIG Wire 1/16"

Couldn't load pickup availability

349 Tool Steel Stick Rod Electrode 1/8"

Couldn't load pickup availability

Welding Container Drawer 19 - Welding PPE

Couldn't load pickup availability

Welding Container Drawer 22 - Cryotaps

Couldn't load pickup availability

Welding Container Drawer 11 - X-Cut Exothermic Cutting System with Rods

Couldn't load pickup availability

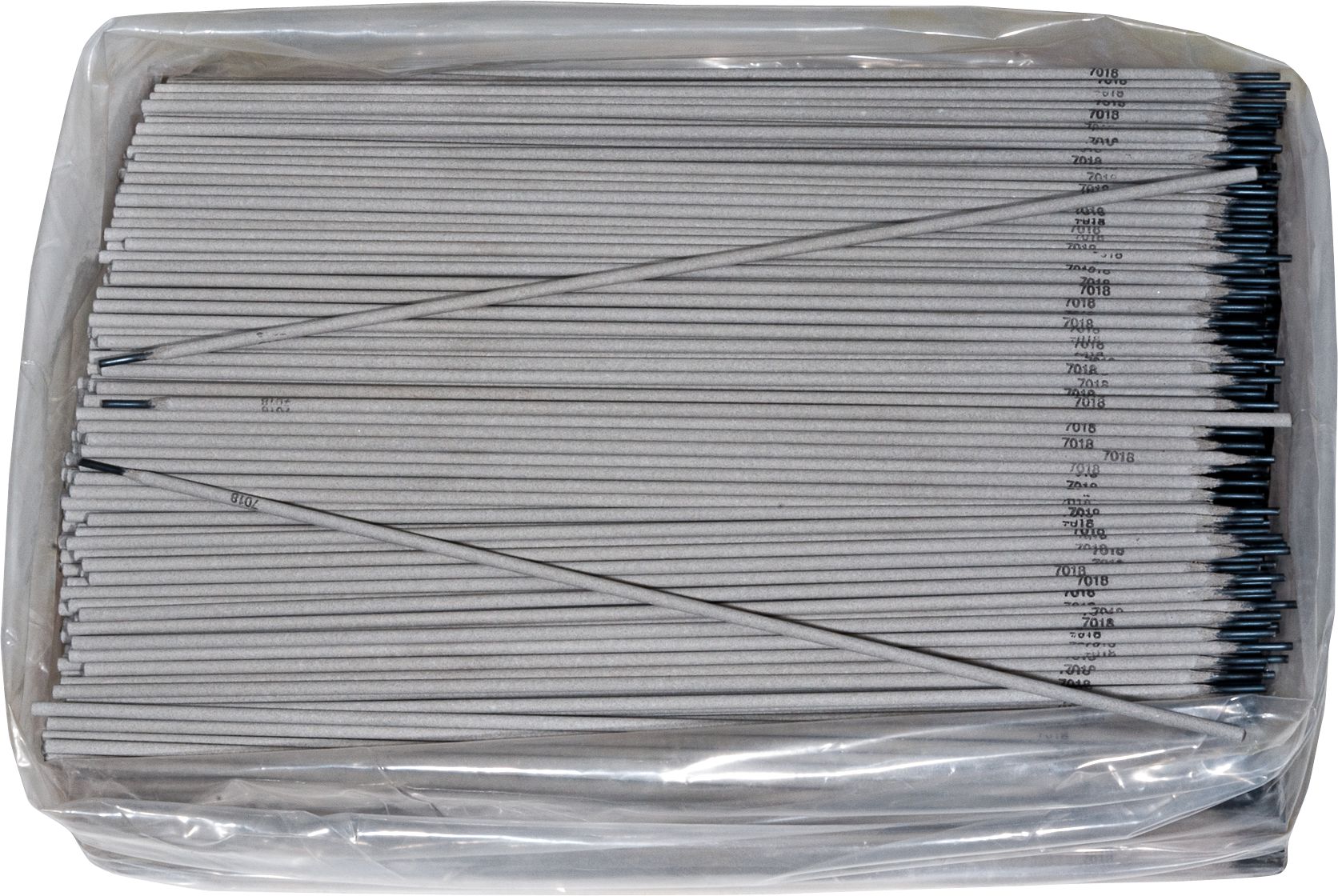

E7018 Mild/Carbon Steel Stick Electrode 3/32"

Couldn't load pickup availability

Mild/Carbon Steel Stick Rod Electrode Assortment

Couldn't load pickup availability

349 Tool Steel TIG Wire 1/16"

Couldn't load pickup availability

Product Description

Specially formulated for welding P-mold steels and most chrome-moly alloy steels.Superior Advantages

• Crack-resistant

• Premium operability

• High wear resistance

Tensile Strength: 89,700 PSIYield Strength: 73,400 PSIElongation: 26%Hardness: Rc 33-36Polarity: DC StraightGas: 100% Ar

Typical Applications

• Die-casting dies

• Injection molds

• Compression molding of plastics and chrome-moly steels like AISI 4130, 4140, 8620 and 8640

Usage ProcedureMaintain a short arc with minimal weave. Preheat as prescribed by base metal.

Technical Specifications

| Item#: | CW4841 |

|---|---|

| Welding Process | TIG |

| Type | Solid |

| Diameter | .020 " |

| Length | 18 " |

| Tensile Strength | 89,700 PSI |

| Yield Strength | 73,400 PSI |

| Elongation | 26 % |

| Base Metal | Tool Steel |

| Hardness | 33-36 HRC |

| Shielding Gas | 100% Ar |

| Polarity | DCSP |

| Quantity Per Package | 25.0000 |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 0.5 lb |

Product Restrictions