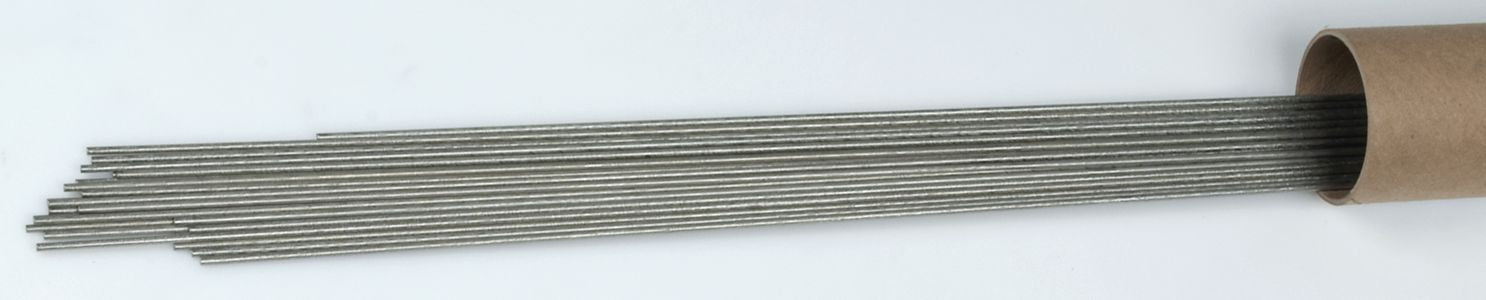

340 Chro-moly MIG Welding Wire 0.035"

(Pack of

25.0)

Specially formulated for welding the 400 Series martensitic stainless steels such as 410, 416 and 420. Primary alloying elements are chromium, nickel and molybdenum so it can also be used on chrome-moly tool steels.

Superior Advantages

• Produces smooth, dense, porosity- and crack-free weld deposits

• Resistant to moderate corrosion and heat scaling (up to 1,200°F)

• Hard with excellent machinability

• Ideally suited for high temperature applications (up to 800°F)

Tensile Strength: 140,000 PSIElongation: 25%Hardness: Rc 40Gas: 98% Ar, 2% O2

Typical Applications

• Tubular frames and roll bars

• Forging dies

• Fractured tools and blades

• Shaft buildup

• Bearing surfaces

• Metal-to-metal wear

Couldn't load pickup availability

California Proposition 65: WARNING: Cancer -

www.P65Warnings.ca.gov

Frequently Bought Together

102 High Strength Steel Electrode 3/16

Couldn't load pickup availability

Metric Indented Hex Head Bolt with 17mm Washer

Couldn't load pickup availability

Molding Clip with Sealer Nylon White 11.5 x 21

Couldn't load pickup availability

Rocker Molding Clip with Sealer Nylon Gray 12mm

Couldn't load pickup availability

Heavy Duty Plastic Welding Rod Protecting Tube

Couldn't load pickup availability

Welding Container Drawer 19 - Welding PPE

Couldn't load pickup availability

Welding Container Drawer 22 - Cryotaps

Couldn't load pickup availability

704 Mild/Carbon Steel Stick Rod Electrode 1/8"

Couldn't load pickup availability

E7018 Mild/Carbon Steel Stick Electrode 1/8"

Couldn't load pickup availability

211 Cast Iron TIG Wire 3/32"

Couldn't load pickup availability

Product Description

Specially formulated for welding the 400 Series martensitic stainless steels such as 410, 416 and 420. Primary alloying elements are chromium, nickel and molybdenum so it can also be used on chrome-moly tool steels.Superior Advantages

• Produces smooth, dense, porosity- and crack-free weld deposits

• Resistant to moderate corrosion and heat scaling (up to 1,200°F)

• Hard with excellent machinability

• Ideally suited for high temperature applications (up to 800°F)

Tensile Strength: 140,000 PSIElongation: 25%Hardness: Rc 40Gas: 98% Ar, 2% O2

Typical Applications

• Tubular frames and roll bars

• Forging dies

• Fractured tools and blades

• Shaft buildup

• Bearing surfaces

• Metal-to-metal wear

Technical Specifications

| Item#: | CW3430 |

|---|---|

| Welding Process | MIG |

| Type | Solid |

| Diameter | .035 " |

| Tensile Strength | 140,000 PSI |

| Elongation | 25 % |

| Base Metal | Chro-moly |

| Hardness | 40 HRC |

| Shielding Gas | 98Ar/2Ox |

| Polarity | DCRP |

| UNSPSC #: | 23271810 |

| TAA Compliant: | No |

| Weight: | 27.0 lb |

Product Restrictions

California Proposition 65: WARNING: Cancer -

www.P65Warnings.ca.gov