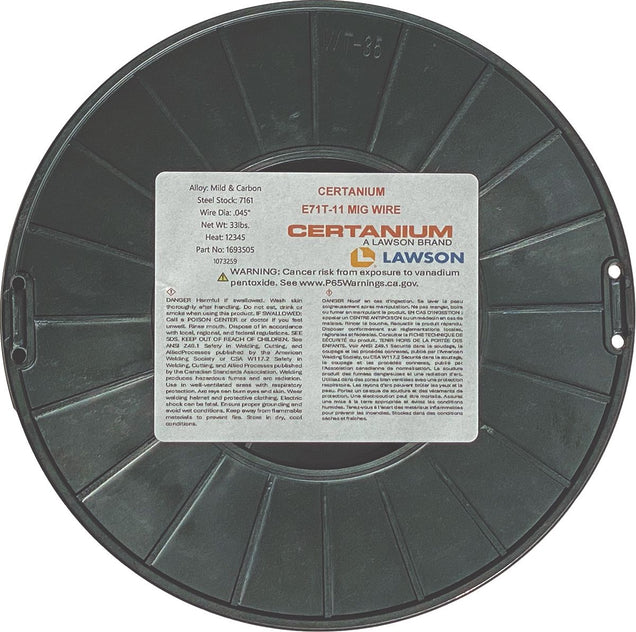

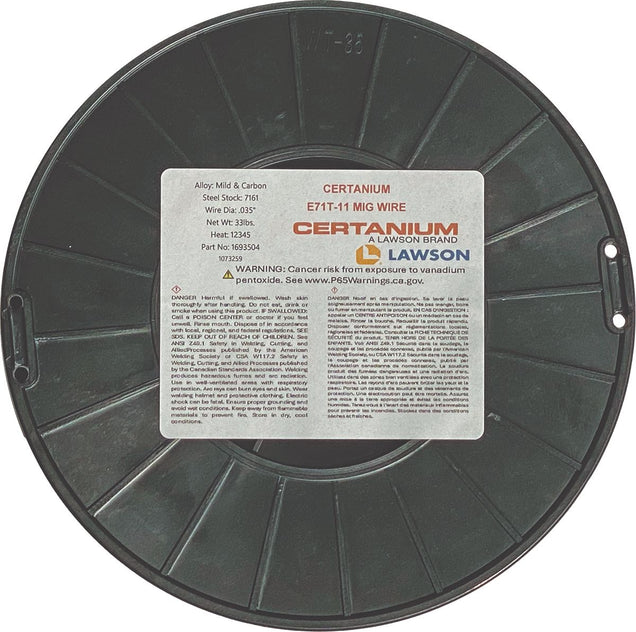

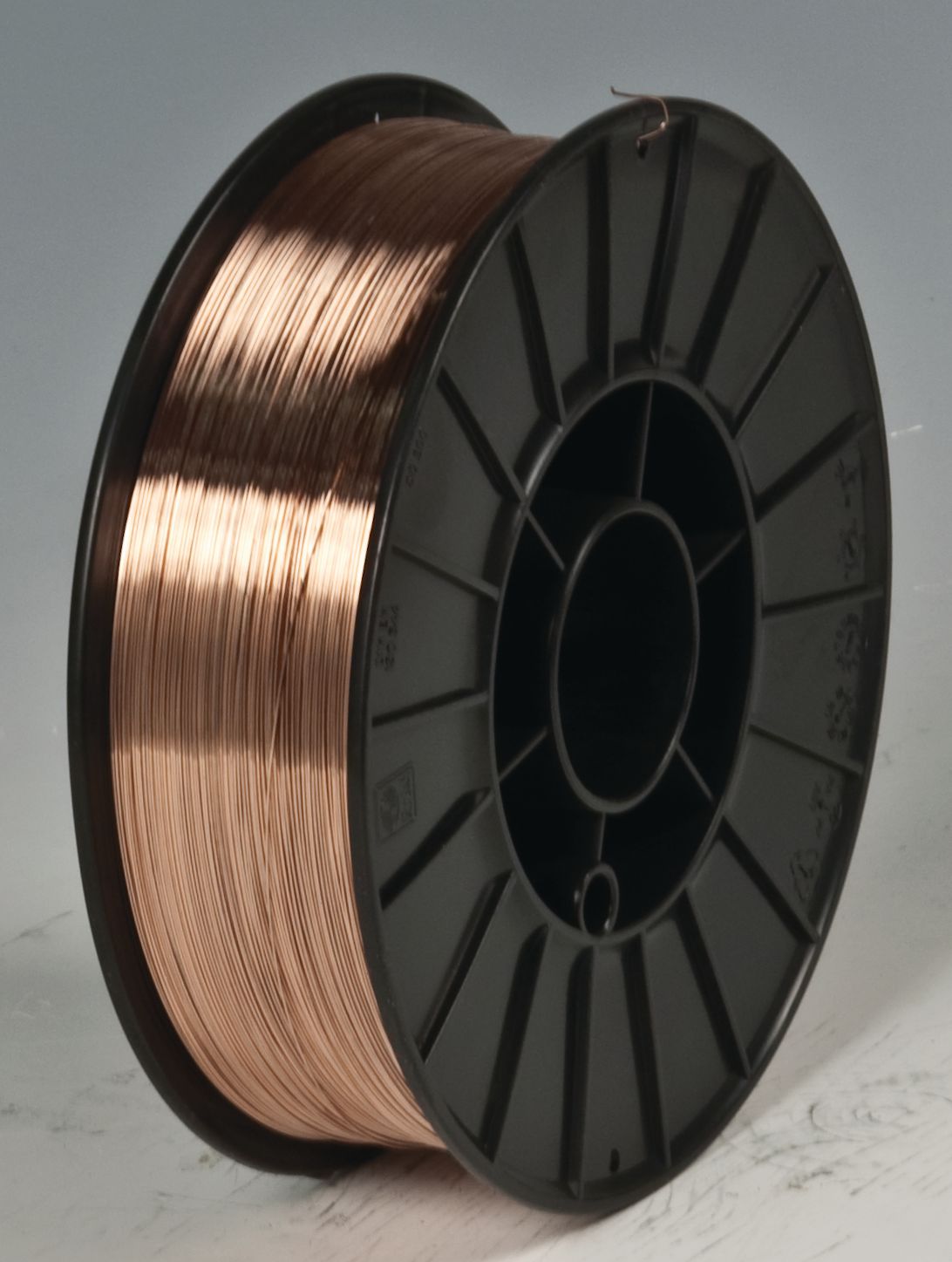

311 Mild and Carbon Steel MIG Welding Wire, Flux Cored, 75Ar/25CO2 Shielding Gas, 29% Elongation, DCRP Polarity, 0.035"

(Pack of

33)

SKU:CW1763 Item#: CW1763

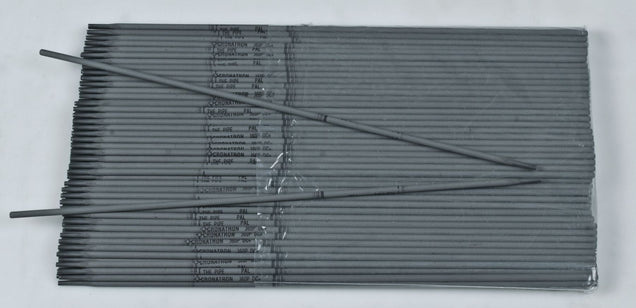

Easy-to-use, all-position electrodes are fully machinable and designed to resist underbead cracking. For use in a variety of applications for everyday maintenance of mild and low-alloy steels.

Superior Advantages

• Fully machinable

• Resists cracking due to high elongation

• Easy slag removal saves time

• Moisture-resistant coating

• Meets or exceeds low-hydrogen requirements

Tensile Strength: 81,000 PSIYield Strength: 72,000 PSIElongation: 29%Gas: 75% Ar, 25% CO2

Typical Applications • Use on free-machining or high sulfur steels• Agriculture equipment• Structural members• Truck bodies and frames• Pipes, flanges, channels, tubes and shafts• Holding tanks, steel vessels

Frequently Bought Together

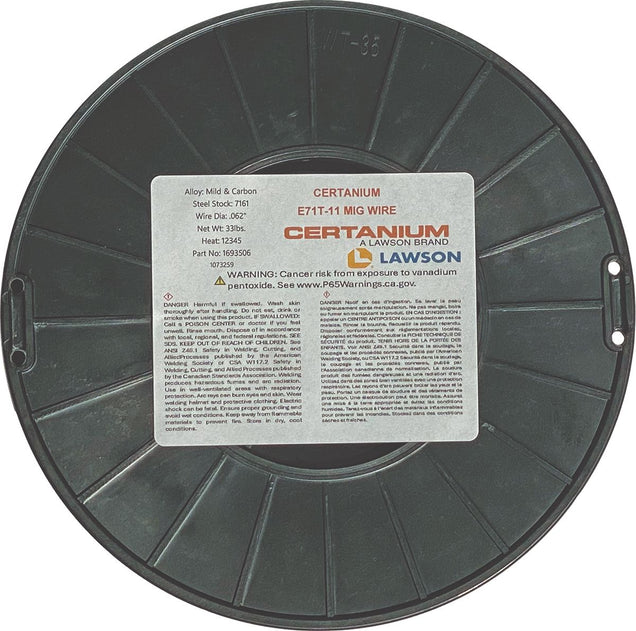

AWS E71T-11 Carbon Steel MIG Flux Core Welding Wire .062" 33lb

Couldn't load pickup availability

AWS E71T-11 Carbon Steel MIG Flux Core Welding Wire .035" 2lb

Couldn't load pickup availability

321 Mild and Carbon Steel MIG Welding Wire 0.024"

Couldn't load pickup availability

Cowl Bumper Fender Liner/Engine Under Cover Rivet

Couldn't load pickup availability

Drive Rivet Nylon M8

Couldn't load pickup availability

Bumper Fascia General Purpose Split Rivet 3/16"

Couldn't load pickup availability

Large MIG Plier

Couldn't load pickup availability

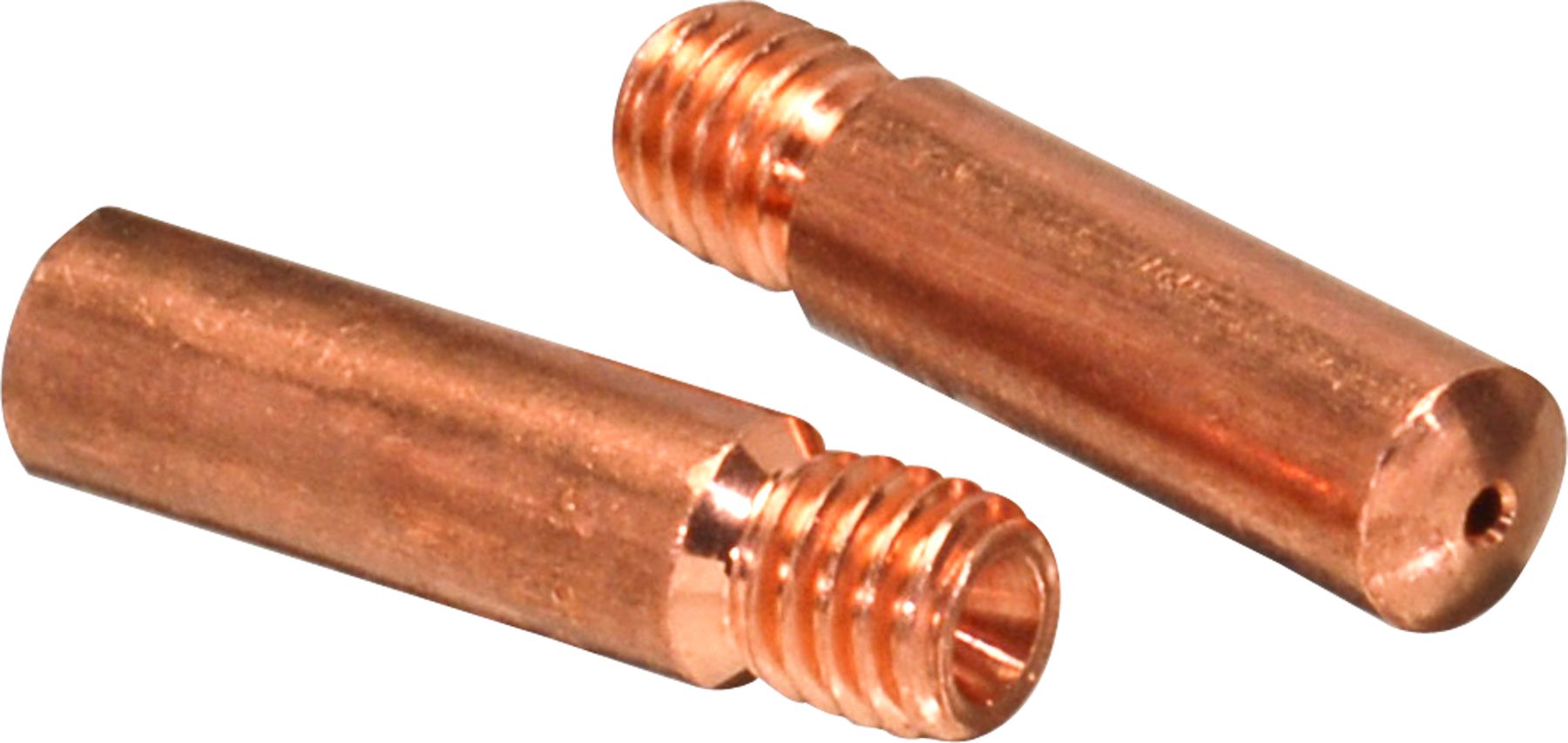

11-35 MIG Welding Contact Tip 0.035"

Couldn't load pickup availability

Rosin Core Solder 0.032"

Couldn't load pickup availability

AWS E71T-11 Carbon Steel MIG Flux Core Welding Wire .062" 33lb

Couldn't load pickup availability

AWS E71T-11 Carbon Steel MIG Flux Core Welding Wire .035" 2lb

Couldn't load pickup availability

9-6003 Plasma Cutting Shield Cup

Couldn't load pickup availability

Product Description

Easy-to-use, all-position electrodes are fully machinable and designed to resist underbead cracking. For use in a variety of applications for everyday maintenance of mild and low-alloy steels.Superior Advantages

• Fully machinable

• Resists cracking due to high elongation

• Easy slag removal saves time

• Moisture-resistant coating

• Meets or exceeds low-hydrogen requirements

Tensile Strength: 81,000 PSIYield Strength: 72,000 PSIElongation: 29%Gas: 75% Ar, 25% CO2

Typical Applications • Use on free-machining or high sulfur steels• Agriculture equipment• Structural members• Truck bodies and frames• Pipes, flanges, channels, tubes and shafts• Holding tanks, steel vessels

Technical Specifications

| Item#: | CW1763 |

|---|---|

| Welding Process | MIG |

| Type | Flux Cored |

| Diameter | .035 " |

| Tensile Strength | 81,000 PSI |

| Yield Strength | 72,000 PSI |

| Elongation | 29 % |

| Base Metal | Mild & Carbon Steel |

| Shielding Gas | 75Ar/25CO2 |

| Polarity | DCRP |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 33.0 lb |

Product Restrictions