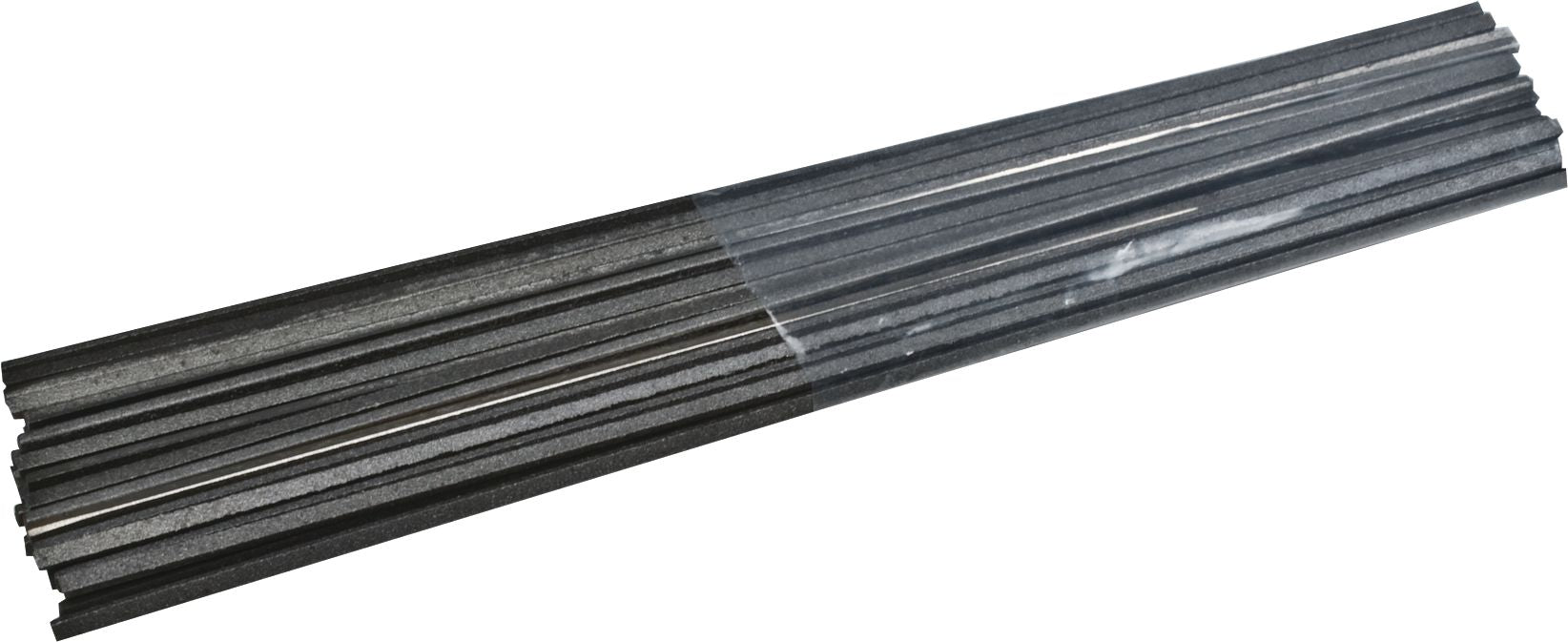

261 Blue Flux Coated General Purpose Silver Brazing Alloy 1/16X18

(Pack of

6)

A low working temperature silver brazing alloy with superb wetting action on difficult-to-join metals such as tool steels, stainless steel, beryllium copper and nickel alloys.

• Fast Flowing – Works well on tight joints

• High Silver Content – Lower melting point and reduces need for high heat for joining

• High-detergent conductivity

• High strength

• Corrosion resistant

• Cadmium-free

• Joint Strength: Up to 60,000 PSI/414 Mpa

• Elongation: 32%

• Working Temperature: 1370°F/743°C

• Electrical Conductivity: 19% IACS

• Corrosion Resistance: Good

• Coating: Blue

PROCEDURES Clean the weld area. Remove all rust, paint, grease, oil and other foreign matter. Maintain joint clearance of 0.003” to 0.005”. Prefluxing is not required; however, additional flux will help in tight joints and may be needed. Heat the weld area to a dull red color using a slightly carburizing flame. Melt off a small amount of alloy and flux. Keep the torch in motion and flow the deposit through the joint. Allow to cool slowly. Remove flux residue with warm water.

Couldn't load pickup availability

California Proposition 65: WARNING: Cancer and Reproductive Harm -

www.P65Warnings.ca.gov

Frequently Bought Together

201 The Elite Blue Flux Coated Brazing Alloy 1/16

Couldn't load pickup availability

54 Aluminum Flux Cored Brazing Rod 1/8"

Couldn't load pickup availability

22 Cast Iron Bare Brazing Rod 3/16"

Couldn't load pickup availability

Torrent Frame Front

Couldn't load pickup availability

One-Handed Reciprocating Saw

Couldn't load pickup availability

345 Tool Steel TIG Wire 5/32"

Couldn't load pickup availability

Front Bumper Drive Rivet Plastic 10mm Hole

Couldn't load pickup availability

Radiator Grille Nut M4.2-1.41

Couldn't load pickup availability

Bumper Drive Rivet Plastic 10mm Hole

Couldn't load pickup availability

40 Silver Flux Coated Brazing Rod 1/16"

Couldn't load pickup availability

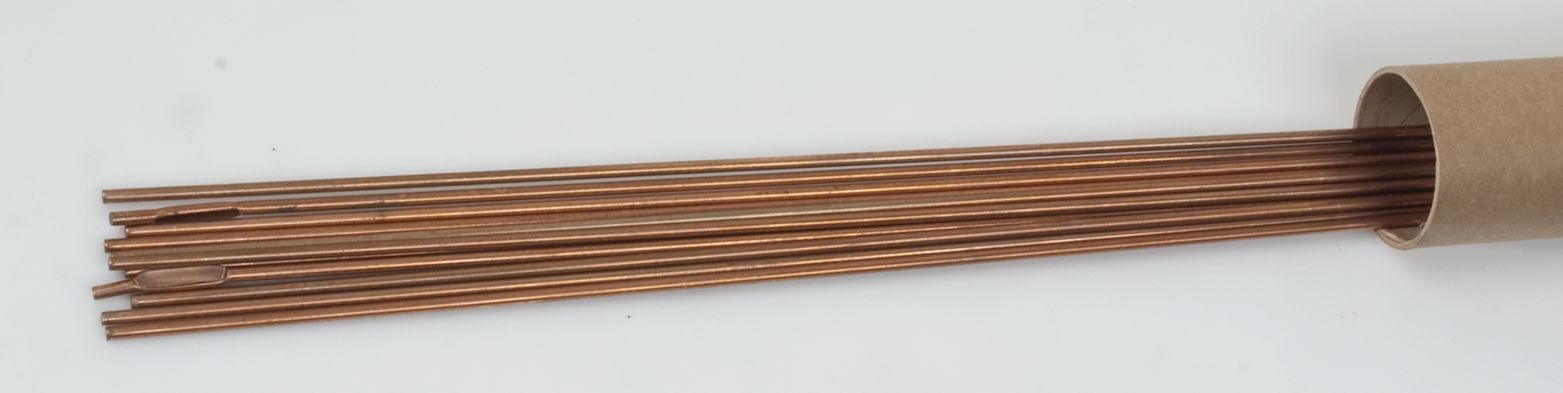

47 Sil-Phos Bare Brazing Rod 1/8"

Couldn't load pickup availability

266 Pink Flux Coated Super Fast Flowing Silver Brasing Alloy 3/64X18

Couldn't load pickup availability

Heat Stick 1050F Degrees

Couldn't load pickup availability

Wear Plates Used By Maintenance Welder 1/4X4X5

Couldn't load pickup availability

Wear Plates Used By Maintenance Welder 3/16X3X4

Couldn't load pickup availability

Product Description

A low working temperature silver brazing alloy with superb wetting action on difficult-to-join metals such as tool steels, stainless steel, beryllium copper and nickel alloys.• Fast Flowing – Works well on tight joints

• High Silver Content – Lower melting point and reduces need for high heat for joining

• High-detergent conductivity

• High strength

• Corrosion resistant

• Cadmium-free

• Joint Strength: Up to 60,000 PSI/414 Mpa

• Elongation: 32%

• Working Temperature: 1370°F/743°C

• Electrical Conductivity: 19% IACS

• Corrosion Resistance: Good

• Coating: Blue

PROCEDURES Clean the weld area. Remove all rust, paint, grease, oil and other foreign matter. Maintain joint clearance of 0.003” to 0.005”. Prefluxing is not required; however, additional flux will help in tight joints and may be needed. Heat the weld area to a dull red color using a slightly carburizing flame. Melt off a small amount of alloy and flux. Keep the torch in motion and flow the deposit through the joint. Allow to cool slowly. Remove flux residue with warm water.

Technical Specifications

| Item#: | EG26170000 |

|---|---|

| Welding Process | Brazing |

| Type | Flux-Coated Brazing Rod |

| Diameter | 1/16 " |

| Length | 18 " |

| Tensile Strength | 70,000 PSI |

| Melting Temperature | 1,295 °F |

| Color | Blue |

| Base Metal | All Metals Except White Metals |

| Recommended Flux | 361 |

| UNSPSC #: | 23271804 |

| TAA Compliant: | Yes |

| Weight: | 0.395 lb |

Product Restrictions

California Proposition 65: WARNING: Cancer and Reproductive Harm -

www.P65Warnings.ca.gov