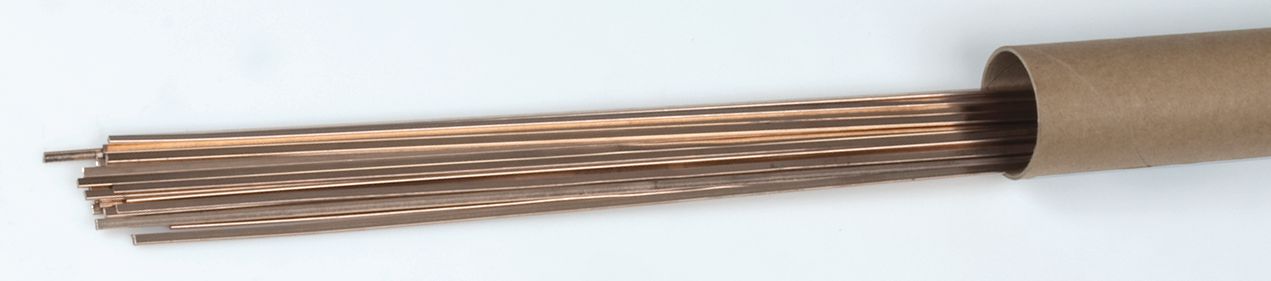

41 Silver Flux Coated Brazing Rod 3/32"

(Pack of

6)

The 41 Silver Flux Coated Brazing Rod delivers exceptional welding performance with its medium silver content that flows smoothly into tight joints while effectively bridging larger gaps. This versatile rod excels at joining copper, stainless steel, bronze alloys, and nickel alloys with its lower melting temperature range of 1,120°F to 1,150°F, making your welding projects more efficient and precise. The pre-applied red flux coating eliminates extra preparation steps, while the rod's superior electrical conductivity and 80,000 PSI tensile strength ensure reliable, long-lasting connections. Whether you're working on electrical components, plumbing systems, or stainless steel fabrication, this brazing rod provides the strength and ductility professional welders demand.

• Thin-flowing for tight joints, yet fills and bridges gaps

• Strong and ductile

• Very good electrical conductivity

Low-temperature application

Flux Coating Color: RedTensile Strength: 80,000 PSIBrazing Range: 1,120°F to 1,150°F (604°C to 621°C)Recommended Flux: F40 (if needed)

Typical Applications

• Electrical rotors, contacts and lugs

• Instrumentation and controls

• Plumbing

• Arts and crafts

• Stainless steel

Usage ProcedureMaterials should be smooth and free of burrs or uneven edges. A carburizing oxyacetylene flame should be used, heating a broad surface along the joint line. Keep the flame cone one inch ahead of the alloy rod and a continuous fillet will form. Clean flux residue off with water.

Couldn't load pickup availability

California Proposition 65: WARNING: Cancer and Reproductive Harm -

www.P65Warnings.ca.gov

Frequently Bought Together

265 Bare Silver Free Flowing Copper Alloy .050X20

Couldn't load pickup availability

45 Silver Bare Brazing Rod 1/16"

Couldn't load pickup availability

266 Pink Flux Coated Super Fast Flowing Silver Brasing Alloy 1/16X18

Couldn't load pickup availability

Bumper and Wheel Well Liner Push-Type Retainer

Couldn't load pickup availability

Woven Polyester Electrical Tape 19mm x 25m

Couldn't load pickup availability

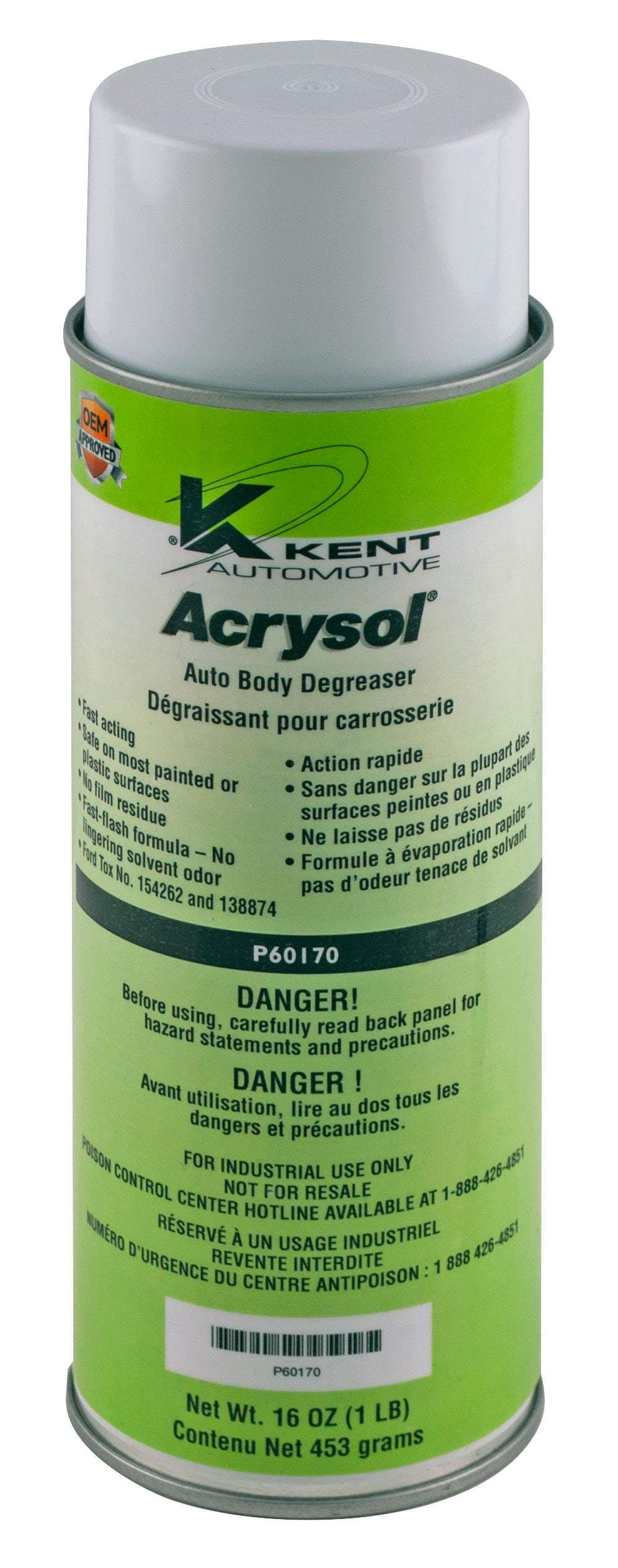

Acrysol Auto Body Degreaser 16oz

Couldn't load pickup availability

41 Silver Flux Coated Brazing Rod 1/16"

Couldn't load pickup availability

46 Sil-Phos Bare Brazing Rod 1/8"

Couldn't load pickup availability

45 Silver Bare Brazing Rod 1/8"

Couldn't load pickup availability

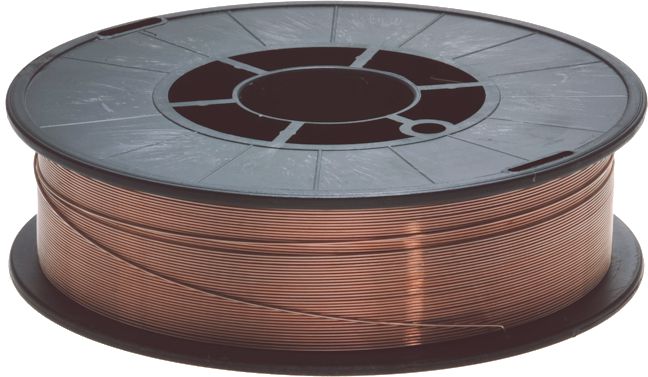

ER70S-6 Mild/Carbon Steel MIG Welding Wire 0.023"

Couldn't load pickup availability

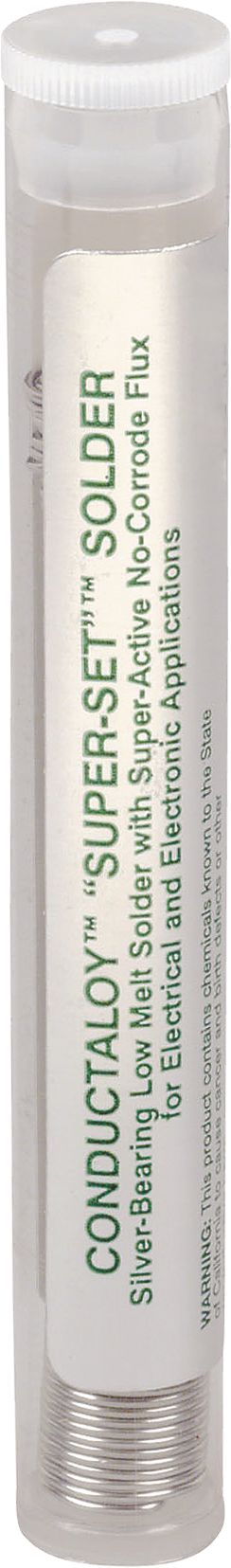

Solid Solder 1/32"

Couldn't load pickup availability

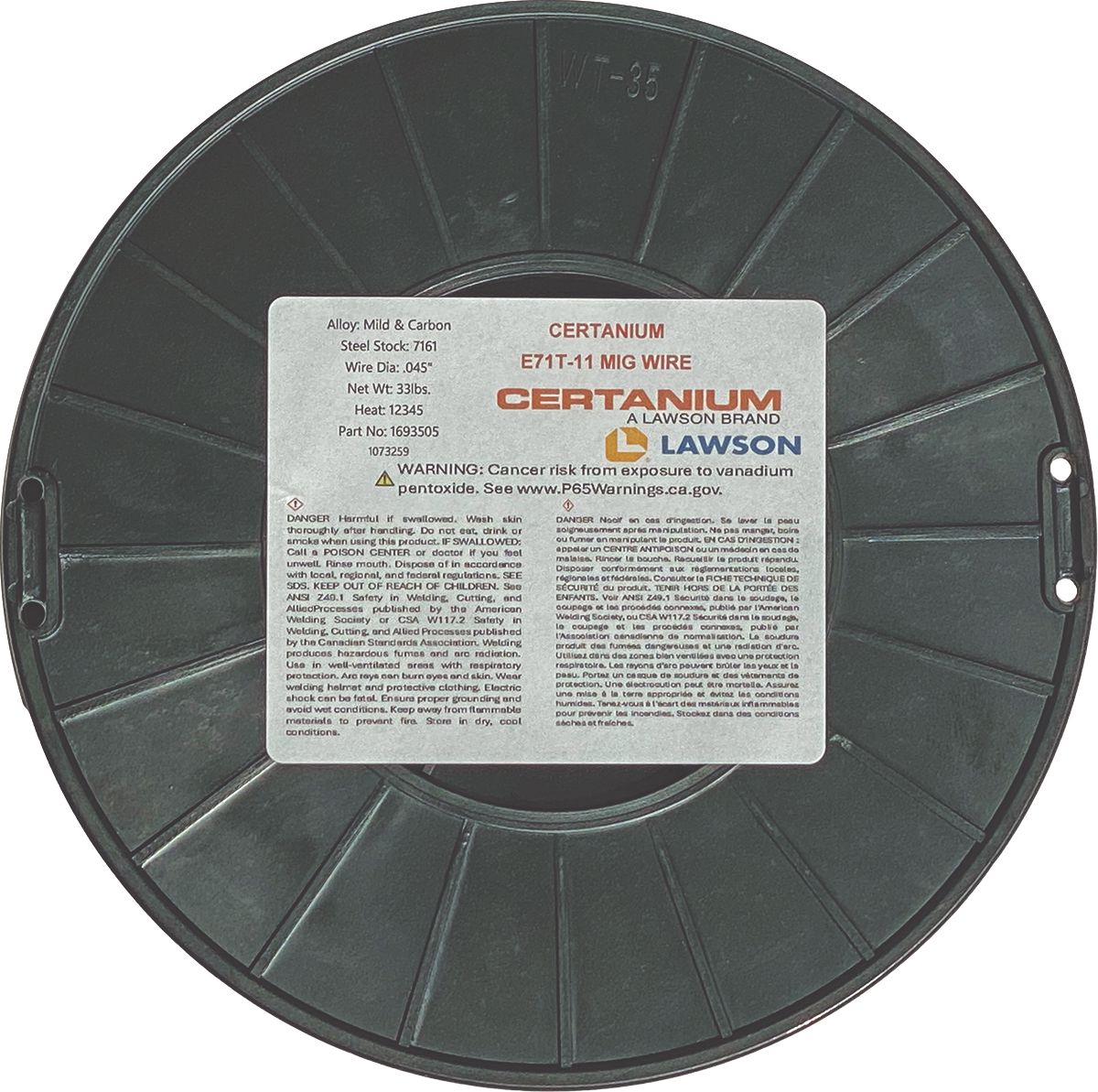

AWS E71T-11 Carbon Steel MIG Flux Core Welding Wire .045" 33lb

Couldn't load pickup availability

Product Description

The 41 Silver Flux Coated Brazing Rod delivers exceptional welding performance with its medium silver content that flows smoothly into tight joints while effectively bridging larger gaps. This versatile rod excels at joining copper, stainless steel, bronze alloys, and nickel alloys with its lower melting temperature range of 1,120°F to 1,150°F, making your welding projects more efficient and precise. The pre-applied red flux coating eliminates extra preparation steps, while the rod's superior electrical conductivity and 80,000 PSI tensile strength ensure reliable, long-lasting connections. Whether you're working on electrical components, plumbing systems, or stainless steel fabrication, this brazing rod provides the strength and ductility professional welders demand.• Thin-flowing for tight joints, yet fills and bridges gaps

• Strong and ductile

• Very good electrical conductivity

Low-temperature application

Flux Coating Color: RedTensile Strength: 80,000 PSIBrazing Range: 1,120°F to 1,150°F (604°C to 621°C)Recommended Flux: F40 (if needed)

Typical Applications

• Electrical rotors, contacts and lugs

• Instrumentation and controls

• Plumbing

• Arts and crafts

• Stainless steel

Usage ProcedureMaterials should be smooth and free of burrs or uneven edges. A carburizing oxyacetylene flame should be used, heating a broad surface along the joint line. Keep the flame cone one inch ahead of the alloy rod and a continuous fillet will form. Clean flux residue off with water.

Technical Specifications

| Item#: | CW1824 |

|---|---|

| Welding Process | Brazing |

| Type | Flux Coating |

| Diameter | 3/32 " |

| Length | 18 " |

| Tensile Strength | 80,000 PSI |

| Melting Temperature | 1120-1150 °F |

| Color | Red |

| Base Metal | Silver |

| Silver Content | Medium |

| Recommended Flux | F40 |

| Description | Medium Silver |

| UNSPSC #: | 23271804 |

| TAA Compliant: | Yes |

| Weight: | 2.0 lb |

Product Restrictions

California Proposition 65: WARNING: Cancer and Reproductive Harm -

www.P65Warnings.ca.gov