46 Sil-Phos Bare Brazing Rod 1/8"

(Pack of

1)

These “sil-phos” alloys provide cost-effective solutions to joining copper and brass alloys.

Superior Advantages

• Thin flow provides excellent capillary action

• No flux required for copper-to-copper applications

• Fills gaps on poor fit-up joints

Fill gaps without affecting joint strength

Brazing Range: 1,325°F to 1,500°F (718°C to 815°C)Recommended Flux: F40 (for dissimilar)

Typical Applications

• Electrical components

• Plumbing and HVAC

• Copper coils and tubing

• Rotors and armatures

Usage ProcedureHeat broad area using large torch tip; a neutral flame is suggested, and a distance of 2" to 3" from the base metal produces the best results. No flux is required on copper-to-copper welds. The joint area should be clean. When the copper turns dull red, the alloy should be applied and the flame should be kept in constant motion ahead of the rod. These alloys are especially effective on long lap joints, fillets and butts.

Couldn't load pickup availability

California Proposition 65: Not Applicable

www.P65Warnings.ca.gov

Frequently Bought Together

241 Premium Aluminum Brazing Alloy 1/8x36

Couldn't load pickup availability

41 Silver Flux Coated Brazing Rod 3/32"

Couldn't load pickup availability

263 Bare Silver Alloy 1/16X6FT

Couldn't load pickup availability

Rear Bumper Cover Retainer Plastic 18mm

Couldn't load pickup availability

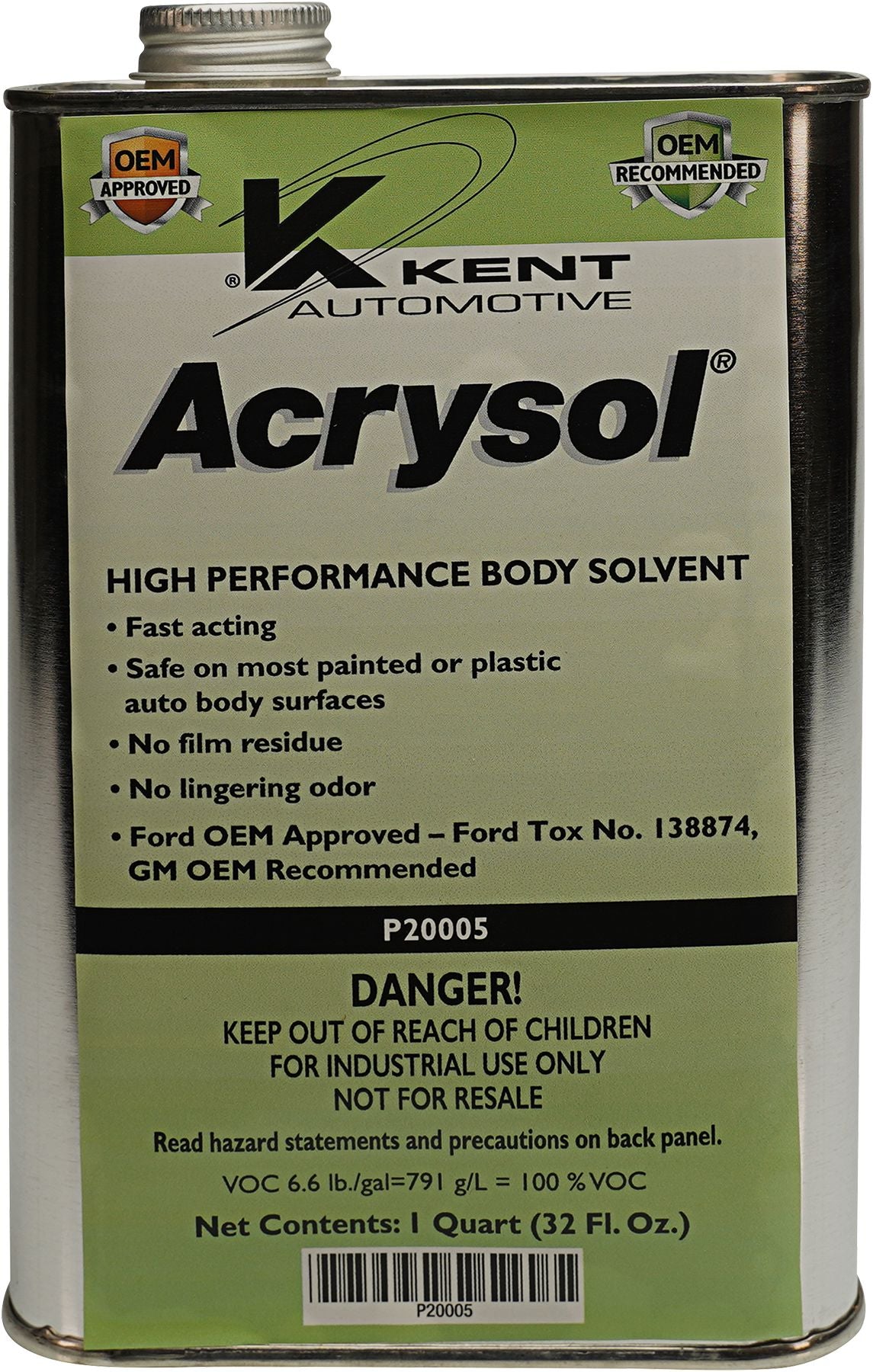

Acrysol Paint Preparation and Auto Body Solvent

Couldn't load pickup availability

Bumper and Wheel Well Liner Push-Type Retainer

Couldn't load pickup availability

41 Silver Flux Coated Brazing Rod 3/32"

Couldn't load pickup availability

263 Bare Silver Alloy 1/16X6FT

Couldn't load pickup availability

40 Silver Flux Coated Brazing Rod 1/16"

Couldn't load pickup availability

Solid Solder 1/32"

Couldn't load pickup availability

ER70S-6 Mild/Carbon Steel MIG Welding Wire 0.03"

Couldn't load pickup availability

ER70S-6 Mild/Carbon Steel MIG Welding Wire 0.023"

Couldn't load pickup availability

Product Description

These “sil-phos” alloys provide cost-effective solutions to joining copper and brass alloys.Superior Advantages

• Thin flow provides excellent capillary action

• No flux required for copper-to-copper applications

• Fills gaps on poor fit-up joints

Fill gaps without affecting joint strength

Brazing Range: 1,325°F to 1,500°F (718°C to 815°C)Recommended Flux: F40 (for dissimilar)

Typical Applications

• Electrical components

• Plumbing and HVAC

• Copper coils and tubing

• Rotors and armatures

Usage ProcedureHeat broad area using large torch tip; a neutral flame is suggested, and a distance of 2" to 3" from the base metal produces the best results. No flux is required on copper-to-copper welds. The joint area should be clean. When the copper turns dull red, the alloy should be applied and the flame should be kept in constant motion ahead of the rod. These alloys are especially effective on long lap joints, fillets and butts.

Technical Specifications

| Item#: | CW5763 |

|---|---|

| Welding Process | Brazing |

| Type | Bare |

| Diameter | 1/8 " |

| Length | 20 " |

| Width | .050 " |

| Melting Temperature | 1325-1500 °F |

| Color | Copper/Silver |

| Base Metal | Sil-Phos |

| Silver Content | Low |

| Recommended Flux | F40 |

| Description | Low Silver |

| UNSPSC #: | 23271804 |

| TAA Compliant: | Yes |

| Weight: | 1.0 lb |

Product Restrictions

California Proposition 65: Not Applicable

www.P65Warnings.ca.gov