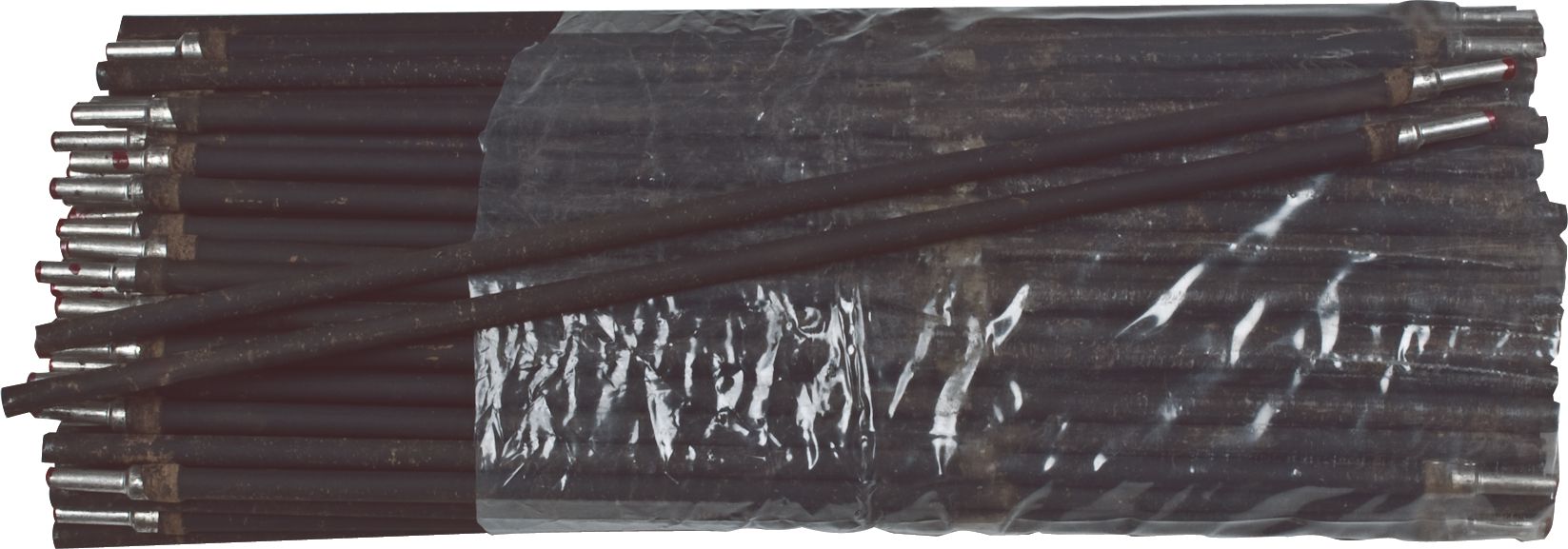

176 Hard Facing Alloy Complex Carbides Excellent Wear And Moderate Impact Polarity Dc Or Ac Hardness 62-64Rc Number Of Passes 2

(Pack of

5)

A hardfacing alloy using elements traditionally found in superalloys. These alloys form complex carbides that exhibit excellent wear and moderate impact resistance. This combination coupled with special stabilizers make it ideal for hardfacing.

• Improved Alloy, 64 Rc – Lasts longer than other hardfacing by up to ten times

• 96% Deposition Efficiency – Almost twice as much metal deposited as a regular electrode

• All Position – 1/4" diameter provides all-position welding, even vertical up

• Operates at Lower Amperages – Reduces base metal dilution to produce longer wearing deposits

• 1/4" can be used on bucket lips as thin as 3/16'' thick

• Designed to withstand abrasion up to 1000˚F/538˚C with good shock and impact resistance

• For use on carbon and abrasion resistant alloy steels including overlaying manganese steels

• Cross-checks readily

• Hardness: 62-64 Rc

• Max Number of Passes: 2

• Current: DC or AC

• Abrasion Resistance: Excellent, 25 times greater than mild steel

• ASTM G65 Abrasion Test: 019.7mm³ vol. loss

Frequently Bought Together

172 Latch Bar And Dutchman Hardfacing Alloy 3/16X18

Couldn't load pickup availability

706 Hard Facing Buildup MIG Welding Wire 1/16"

Couldn't load pickup availability

7500 Martensitic MIG Welding Wire 0.045"

Couldn't load pickup availability

7350 Carbide Hard Facing Stick Rod Electrode 1/2"

Couldn't load pickup availability

7230 Carbide Hard Facing Stick Rod Electrode 3/8"

Couldn't load pickup availability

7370 Carbide Hard Facing Stick Rod Electrode 3/8"

Couldn't load pickup availability

Fender Apron Drive Rivet 8mm Hole

Couldn't load pickup availability

Front Fender Push-Type Retainer Nylon 20mm

Couldn't load pickup availability

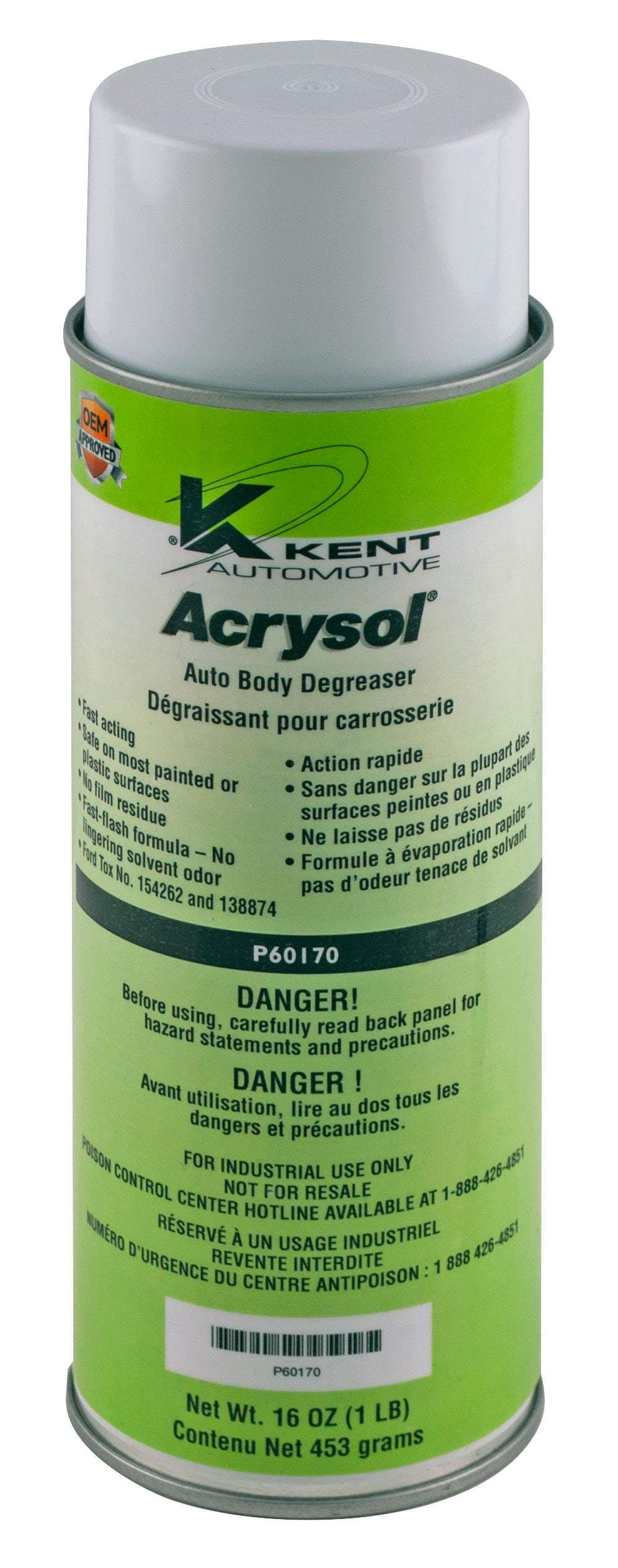

Acrysol Auto Body Degreaser 16oz

Couldn't load pickup availability

Solid Solder 1/32"

Couldn't load pickup availability

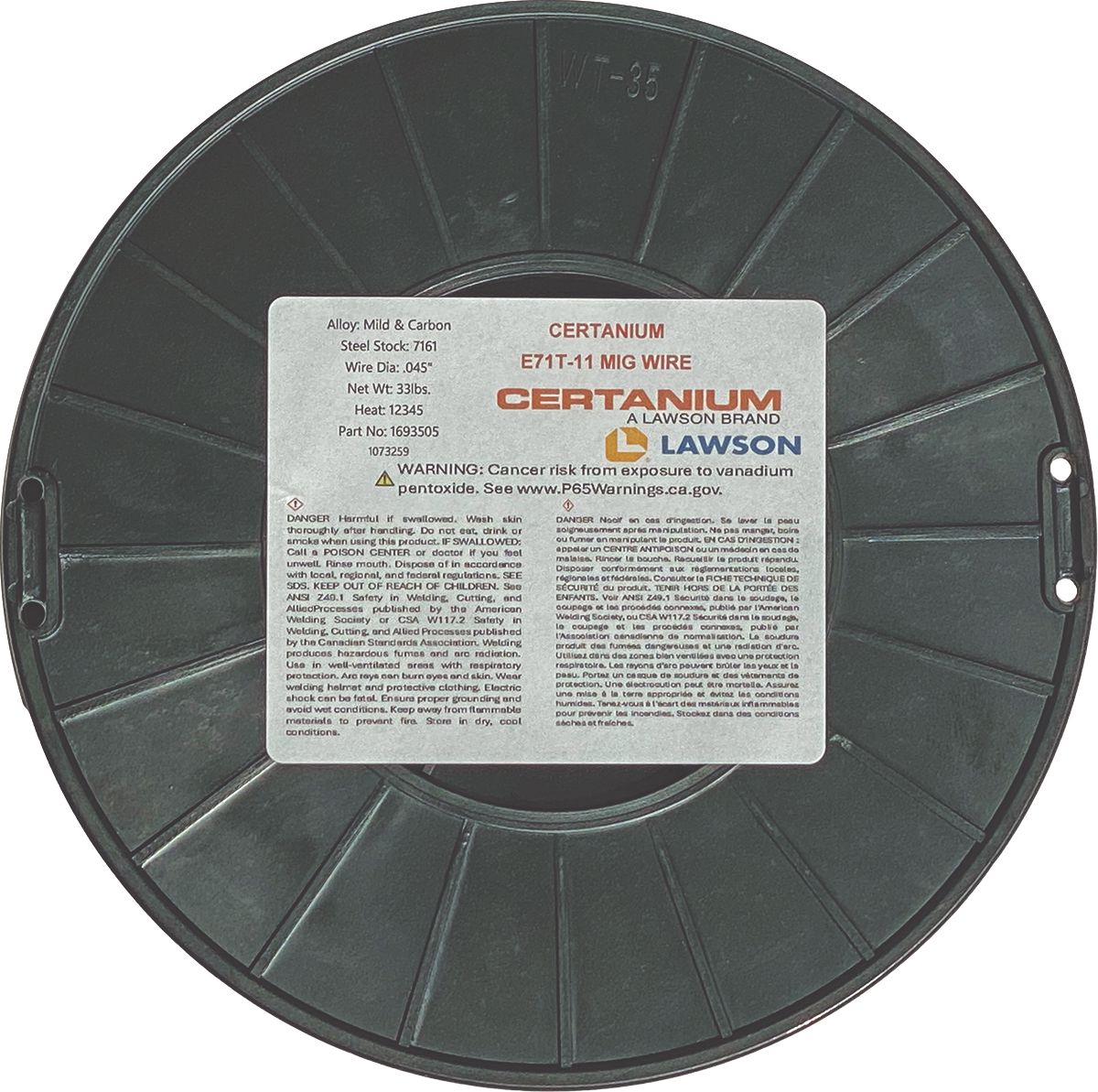

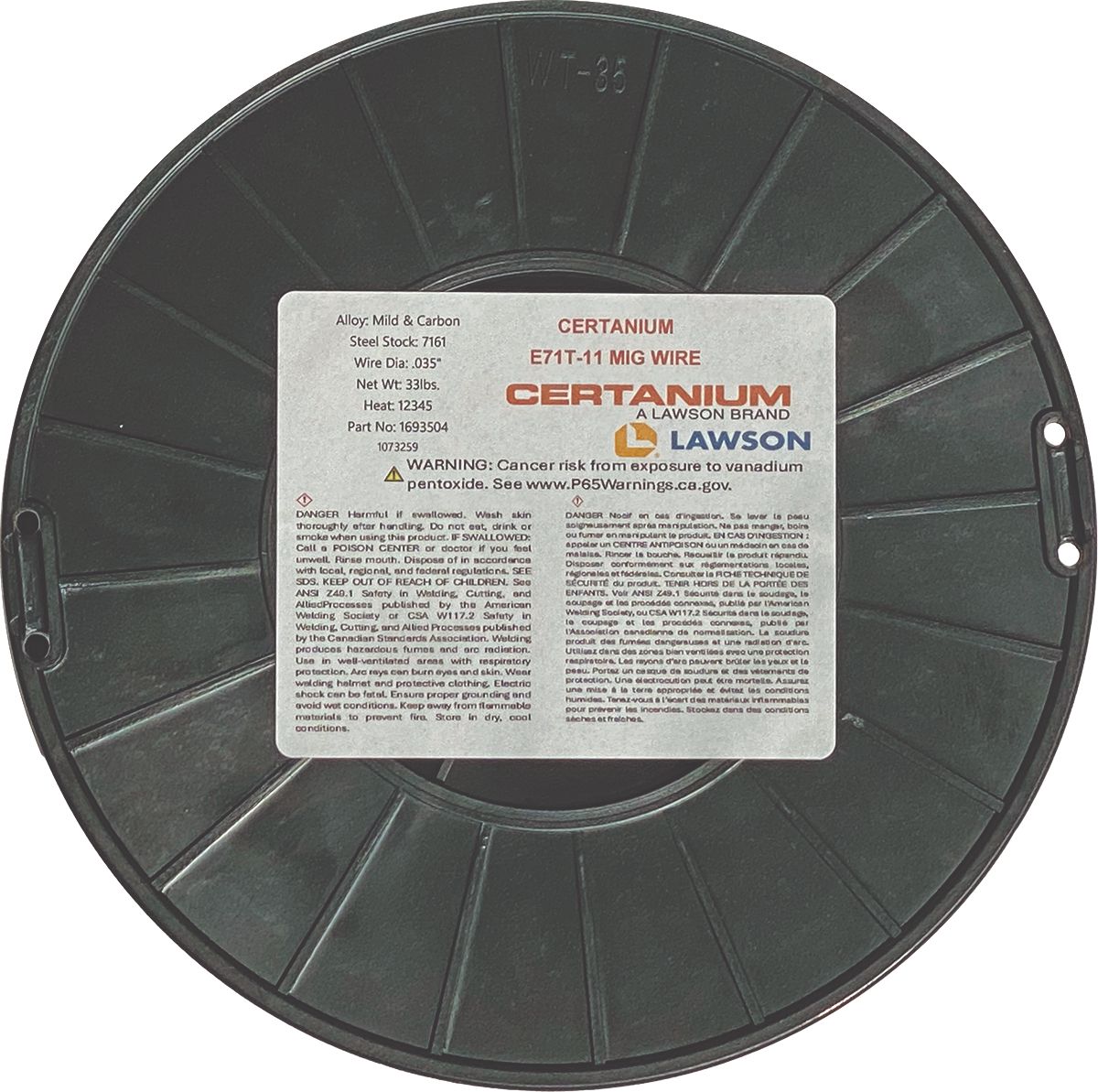

AWS E71T-11 Carbon Steel MIG Flux Core Welding Wire .045" 33lb

Couldn't load pickup availability

AWS E71T-11 Carbon Steel MIG Flux Core Welding Wire .035" 33lb

Couldn't load pickup availability

Product Description

A hardfacing alloy using elements traditionally found in superalloys. These alloys form complex carbides that exhibit excellent wear and moderate impact resistance. This combination coupled with special stabilizers make it ideal for hardfacing.• Improved Alloy, 64 Rc – Lasts longer than other hardfacing by up to ten times

• 96% Deposition Efficiency – Almost twice as much metal deposited as a regular electrode

• All Position – 1/4" diameter provides all-position welding, even vertical up

• Operates at Lower Amperages – Reduces base metal dilution to produce longer wearing deposits

• 1/4" can be used on bucket lips as thin as 3/16'' thick

• Designed to withstand abrasion up to 1000˚F/538˚C with good shock and impact resistance

• For use on carbon and abrasion resistant alloy steels including overlaying manganese steels

• Cross-checks readily

• Hardness: 62-64 Rc

• Max Number of Passes: 2

• Current: DC or AC

• Abrasion Resistance: Excellent, 25 times greater than mild steel

• ASTM G65 Abrasion Test: 019.7mm³ vol. loss

Technical Specifications

| Item#: | EG17610500 |

|---|---|

| Welding Process | Stick |

| Type | Electrode |

| Diameter | 1/2 " |

| Base Metal | Steel To Steel |

| Hardness | 62-64 HRC |

| Polarity | DCEP |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 6.11 lb |