7500 Martensitic Hard Facing MIG Welding Wire, Flux Cored, 55 to 60 HRC Hardness, 75Ar/25C02 Shielding Gas, DCRP Polarity, 0.045"

(Pack of

10)

The 7500 Martensitic MIG Welding Wire is engineered for superior metal repair in applications demanding moderate abrasion resistance and impact durability. Perfect for metal-to-metal wear, this heat-treatable and torch-cuttable wire excels in tasks like refurbishing dredger teeth, conveyor screws, shredders, and shear blades. With unlimited pass-over-pass capability, it ensures lasting performance even in the toughest conditions. Whether you’re maintaining mining equipment or heavy construction machinery, this wire delivers reliable impact resistance and wear protection where it’s needed most.

• Good for metal-to-metal wear

• Torch cuttable

• Heat-treatable

• Unlimited pass-over-pass applications

• Provides good impact resistance

High alloy martensitic flux-cored hardfacing wire for moderate abrasion and impact

Hardness: Rc 55-60Polarity: DC ReverseGas: 75% Ar, 25% CO2 or 100% CO2

Typical Applications

• Dredger and shovel teeth

• Hammers

• Conveyor screws

• Shredders

• Shear blades

• Torch cuttable alloy for buildup • Exceptional impact and abrasive wear resistance

Technical TipNot recommended for austenitic manganese steel without a buffer layer of 7770M-FC.

Frequently Bought Together

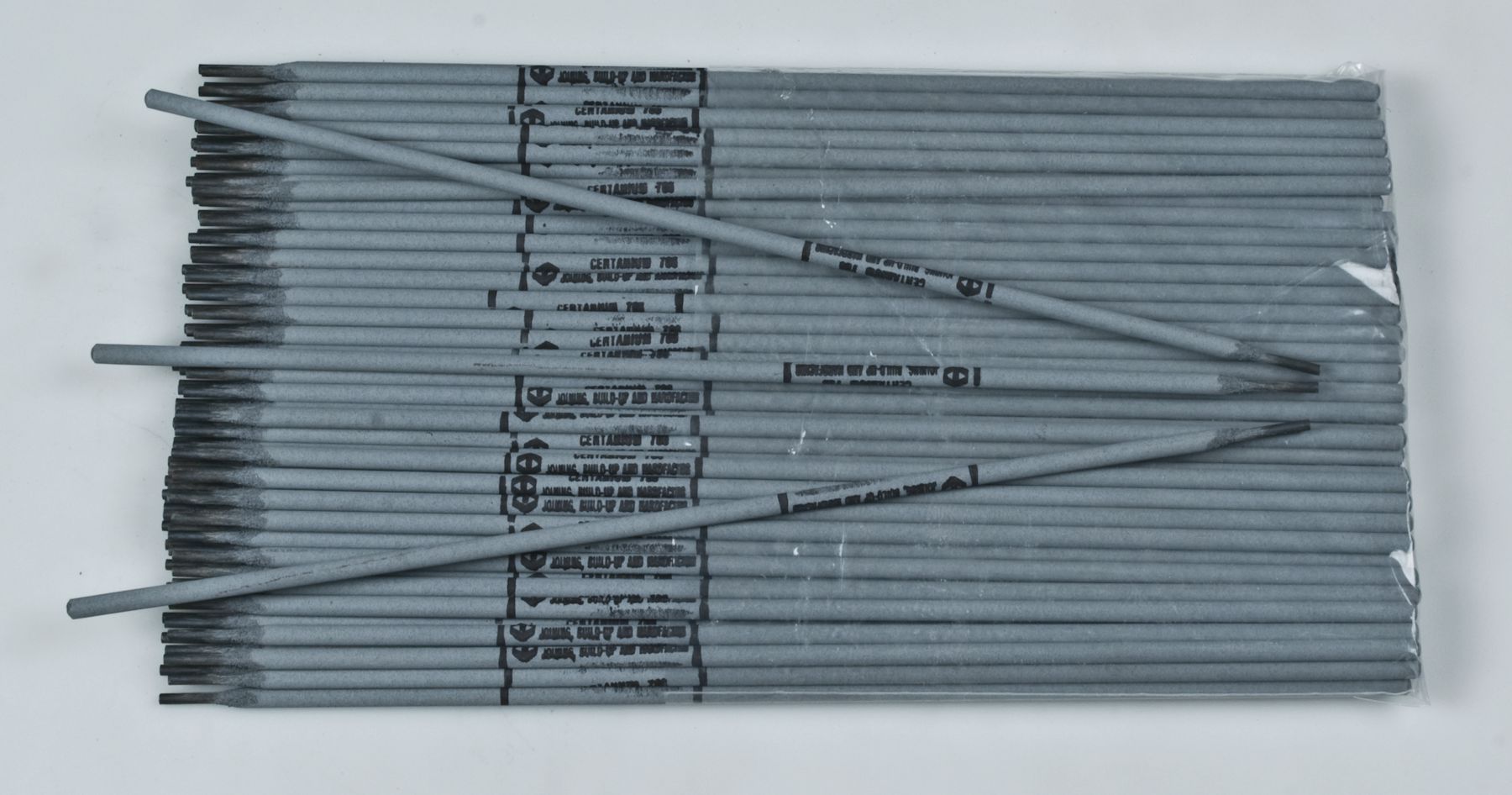

706 Hard Facing Buildup Stick Rod Electrode 3/32"

Couldn't load pickup availability

706 Hard Facing Buildup Stick Rod Electrode 1/8"

Couldn't load pickup availability

246 Carbide Hard Facing Stick Rod Electrode 1/2"

Couldn't load pickup availability

172 Intermediate Abrasion And Impact Alloy 5/32X18

Couldn't load pickup availability

281 Martensitic Stick Rod Electrode 1/8"

Couldn't load pickup availability

172 Latch Bar And Dutchman Hardfacing Alloy 1/8X18

Couldn't load pickup availability

Acrysol Auto Body Degreaser 16oz

Couldn't load pickup availability

Fender Bumper Shield Retainer 11/16"

Couldn't load pickup availability

Woven Polyester Electrical Tape 19mm x 25m

Couldn't load pickup availability

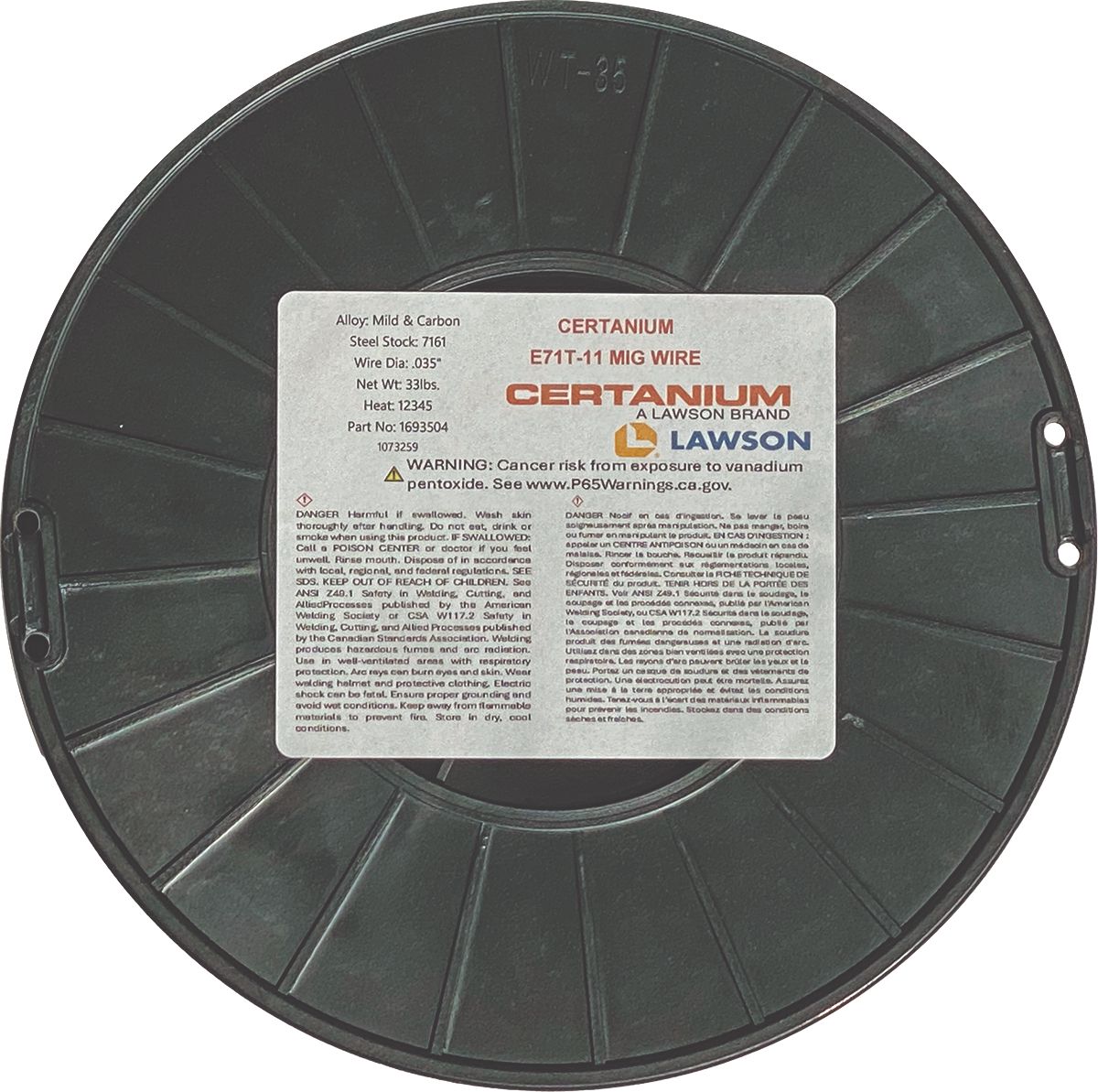

AWS E71T-11 Carbon Steel MIG Flux Core Welding Wire .035" 33lb

Couldn't load pickup availability

AWS E71T-11 Carbon Steel MIG Flux Core Welding Wire .062" 33lb

Couldn't load pickup availability

AWS E71T-11 Carbon Steel MIG Flux Core Welding Wire .035" 2lb

Couldn't load pickup availability

Product Description

The 7500 Martensitic MIG Welding Wire is engineered for superior metal repair in applications demanding moderate abrasion resistance and impact durability. Perfect for metal-to-metal wear, this heat-treatable and torch-cuttable wire excels in tasks like refurbishing dredger teeth, conveyor screws, shredders, and shear blades. With unlimited pass-over-pass capability, it ensures lasting performance even in the toughest conditions. Whether you’re maintaining mining equipment or heavy construction machinery, this wire delivers reliable impact resistance and wear protection where it’s needed most.• Good for metal-to-metal wear

• Torch cuttable

• Heat-treatable

• Unlimited pass-over-pass applications

• Provides good impact resistance

High alloy martensitic flux-cored hardfacing wire for moderate abrasion and impact

Hardness: Rc 55-60Polarity: DC ReverseGas: 75% Ar, 25% CO2 or 100% CO2

Typical Applications

• Dredger and shovel teeth

• Hammers

• Conveyor screws

• Shredders

• Shear blades

• Torch cuttable alloy for buildup • Exceptional impact and abrasive wear resistance

Technical TipNot recommended for austenitic manganese steel without a buffer layer of 7770M-FC.

Technical Specifications

| Item#: | CW5169 |

|---|---|

| Welding Process | MIG |

| Type | Flux Cored |

| Diameter | .045 " |

| Base Metal | Martensitic |

| Hardness | 55-60 HRC |

| Shielding Gas | 75Ar/25C02 |

| Polarity | DCRP |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 11.4 lb |

Product Restrictions