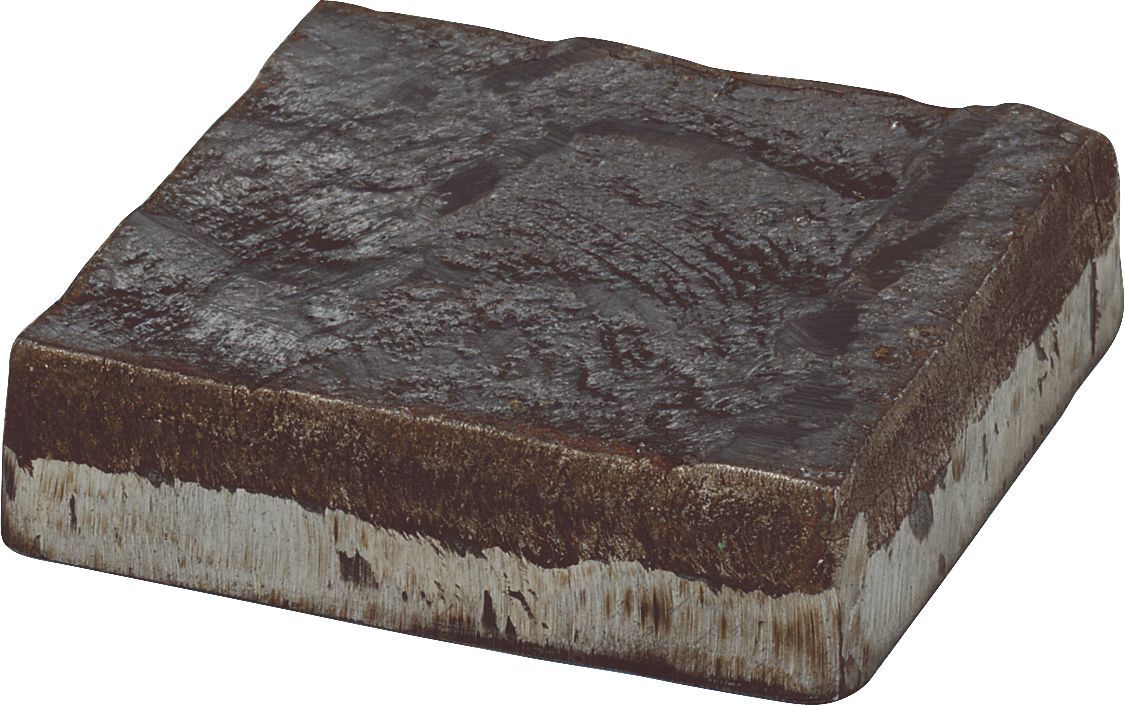

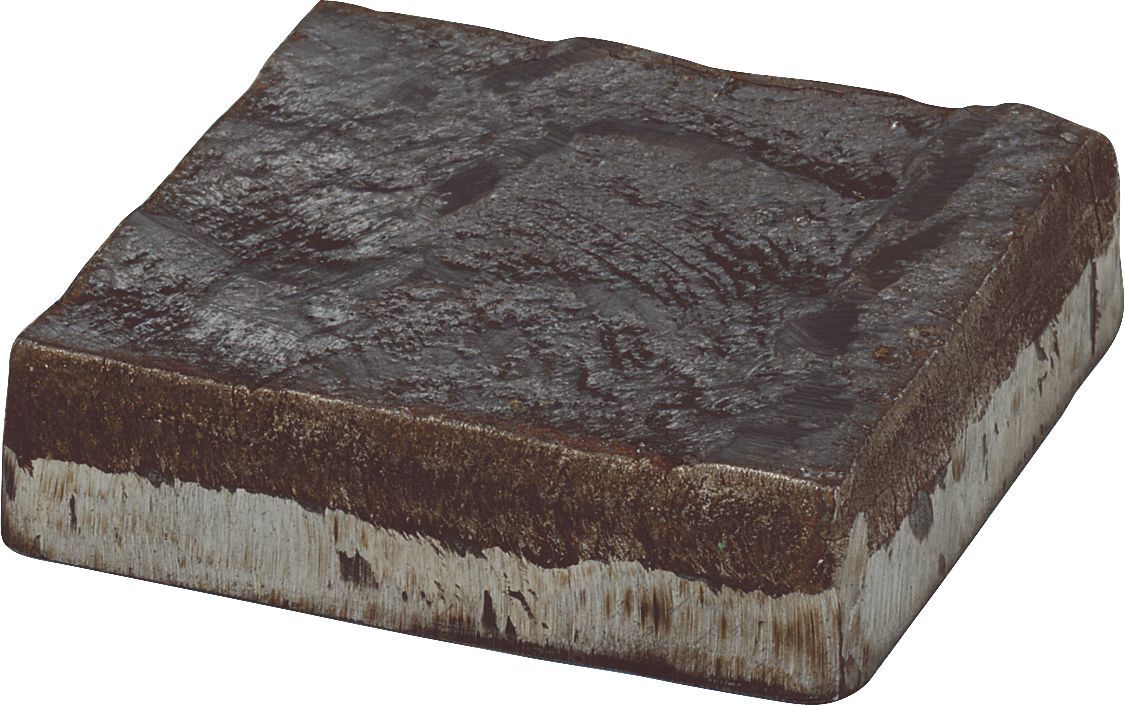

178 Outstanding Abrasion Resitance At High Temparature At 1400F Complex Carbides Polarity Dcep Harness 63-66Rc Number Of Passes 2

(Pack of

5)

• Ultra-Brade SD utilizes a complex carbide alloy system that provides outstanding abrasion resistance even at high temperatures.

• Tubular electrode design provides 90% deposition efficiency

• Reduces smoke by half compared to conventional hardfacing electrodes

• Runs at lower amperage — reduces distortion, weld dilution andmetal fatigue

• Hardness of up to 66 Rc, one layer can outlast two layers of competitive product

• Designed to withstand extreme temperature abrasion up to 1400˚F (760˚C)

• Not designed for impact resistance

• Hardness: 63-66 Rc (deposits will relief check crack readily) • Max deposit thickness: 2 layersCurrent: DCEP (DC+) or AC • Abrasion resistance: Excellent • ASTM G65 Procedure A (Dry sand rubber wheel abrasion test):- 10.51 mm3 volume loss- 0.072 gm mass loss • For comparison sintered tungsten carbide: 0.039 to 0.080 gm mass loss

Frequently Bought Together

281 Martensitic Stick Rod Electrode 1/8"

Couldn't load pickup availability

670 Fc Build Up Flux Core For Carbon And Low Alloy Steels 1/16X33LB

Couldn't load pickup availability

7350 Carbide Hard Facing Stick Rod Electrode 1/4"

Couldn't load pickup availability

176 Extreme Abrasion With Impact 3/8X18IN

Couldn't load pickup availability

676 Flux Core Wire Extreme Abrasion Moderate Impact 1/16X33LBS

Couldn't load pickup availability

174 Gray High Abrasion Moderate Impact 3/16

Couldn't load pickup availability

Front Fender Push-Type Retainer Nylon 20mm

Couldn't load pickup availability

Rocker Panel Molding Clip Nylon White 12 x 20mm

Couldn't load pickup availability

Rocker Molding Clip with Sealer Nylon Blue 17mm

Couldn't load pickup availability

3/8 on 3/8 Dimension I Double Pass Overlay

Couldn't load pickup availability

Industrial Graphite Rod 1 x 12"

Couldn't load pickup availability

1/4 on 1/4 Dimension I Double Pass Overlay

Couldn't load pickup availability

Product Description

• Ultra-Brade SD utilizes a complex carbide alloy system that provides outstanding abrasion resistance even at high temperatures.• Tubular electrode design provides 90% deposition efficiency

• Reduces smoke by half compared to conventional hardfacing electrodes

• Runs at lower amperage — reduces distortion, weld dilution andmetal fatigue

• Hardness of up to 66 Rc, one layer can outlast two layers of competitive product

• Designed to withstand extreme temperature abrasion up to 1400˚F (760˚C)

• Not designed for impact resistance

• Hardness: 63-66 Rc (deposits will relief check crack readily) • Max deposit thickness: 2 layersCurrent: DCEP (DC+) or AC • Abrasion resistance: Excellent • ASTM G65 Procedure A (Dry sand rubber wheel abrasion test):- 10.51 mm3 volume loss- 0.072 gm mass loss • For comparison sintered tungsten carbide: 0.039 to 0.080 gm mass loss

Technical Specifications

| Item#: | EG17800375 |

|---|---|

| Welding Process | Stick |

| Type | Electrode |

| Diameter | 3/8 " |

| Length | 18 " |

| Base Metal | Steel To Steel |

| Hardness | 63-66 HRC |

| Polarity | DCEP |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 6.17 lb |