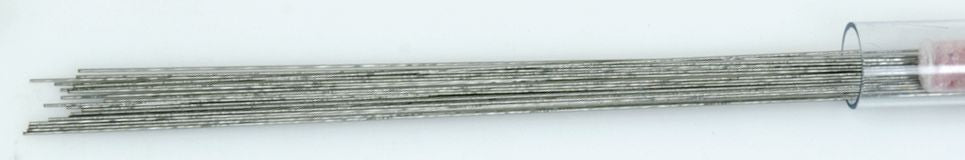

346 Tool Steel TIG Wire, Solid, 56 to 62 HRC Hardness, 100% Ar Shielding Gas, DCSP Polarity, 36" Length, 1/16"

(Pack of

2)

A broad selection of premium alloys to use for nearly any tool steel application and repair.

Superior Advantages

• Crack-resistant

• Premium operability

• High wear resistance

Hardness: Rc 56-62Polarity: DC StraightGas: 100% Ar

“A” Series, Medium Alloy Cold Work SteelAn air-hardening tool steel containing manganese, chromium, molybdenum and vanadium. These alloying elements provide deep air-hardening characteristics with minimal distortion. This alloy also has a high carbon content providing weld deposits with high wear resistance. Types: A2, 4, 6.

Typical Applications

• Various tool steel repairs – specific alloy selection is dependent upon the type (or Series) of tool steel being repaired

• Forming dies, cutting tools and high impact tools

Frequently Bought Together

Shroud Insulating Button Nylon 11/16"

Couldn't load pickup availability

Phillips Truss Head Sheet Metal Screw Steel 15mm

Couldn't load pickup availability

Front Bumper and Radiator Support Drive Rivet

Couldn't load pickup availability

345 Tool Steel Stick Rod Electrode 3/32"

Couldn't load pickup availability

344 Tool Steel Stick Rod Electrode 3/32"

Couldn't load pickup availability

349 Tool Steel TIG Wire 0.02"

Couldn't load pickup availability

Heat Stick 1050F Degrees

Couldn't load pickup availability

Wear Plates Used By Maintenance Welder 1/4X4X5

Couldn't load pickup availability

Wear Plates Used By Maintenance Welder 3/16X3X4

Couldn't load pickup availability

161 Arc Prep Metal Working Electrode 1/8

Couldn't load pickup availability

704 Mild/Carbon Steel Stick Rod Electrode 1/8"

Couldn't load pickup availability

E7018 Mild/Carbon Steel Stick Electrode 1/8"

Couldn't load pickup availability

Product Description

A broad selection of premium alloys to use for nearly any tool steel application and repair.Superior Advantages

• Crack-resistant

• Premium operability

• High wear resistance

Hardness: Rc 56-62Polarity: DC StraightGas: 100% Ar

“A” Series, Medium Alloy Cold Work SteelAn air-hardening tool steel containing manganese, chromium, molybdenum and vanadium. These alloying elements provide deep air-hardening characteristics with minimal distortion. This alloy also has a high carbon content providing weld deposits with high wear resistance. Types: A2, 4, 6.

Typical Applications

• Various tool steel repairs – specific alloy selection is dependent upon the type (or Series) of tool steel being repaired

• Forming dies, cutting tools and high impact tools

Technical Specifications

| Item#: | CW1892 |

|---|---|

| Welding Process | TIG |

| Type | Solid |

| Diameter | 1/16 " |

| Length | 36 " |

| Base Metal | Tool Steel |

| Hardness | 56-62 HRC |

| Shielding Gas | 100% Ar |

| Polarity | DCSP |

| Quantity Per Package | 2.0000 |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 2.0 lb |

Product Restrictions