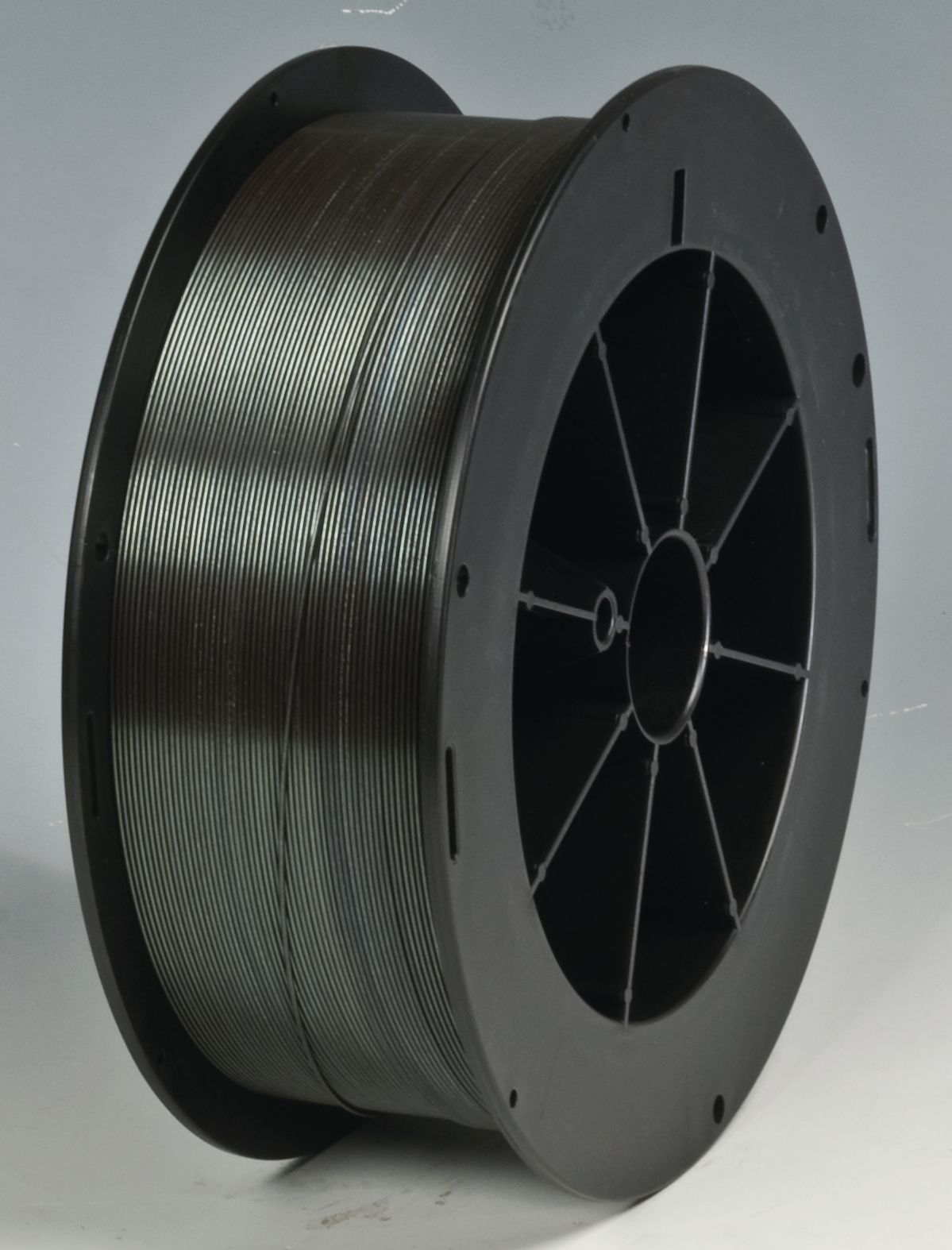

H7 Carbide Hard Facing MIG Welding Wire, Flux Cored, 53 to 60 HRC Hardness, DCRP Polarity, Crushers and Hammers, 1/16"

(Pack of

25)

Maximize the durability of your industrial equipment with the H7 Carbide Hardfacing MIG Welding Wire. Designed to create a tough, wear-resistant layer, this welding wire is perfect for protecting metal surfaces exposed to extreme abrasion, impact, or friction. Commonly used in mining, construction, and agriculture, it extends the lifespan of components like power plant fan blades, rotary tiller blades, and screw shafts. With excellent crack resistance, it ensures reinforced parts stay strong even in flexing or fatigue-heavy applications.

• All VX wires are self-shielding, saving money on gas

• Our technical team will work closely with you to determine the best product for your specific application

Significant abrasion resistance with low impact characteristics

Specifications: Moderate chrome carbide CrCHardness: Rc 60No. of Passes: Up to three

Typical Applications

• Buckets and dozer blades

• Dump beds and truck liners

• Chutes and augers

• Crushers and hammers

Frequently Bought Together

7222 Carbide Hard Facing Stick Rod Electrode 1/4"

Couldn't load pickup availability

7220 Carbide Hard Facing Stick Rod Electrode 1/2"

Couldn't load pickup availability

711 Carbide Hard Facing Stick Rod Electrode 3/16"

Couldn't load pickup availability

246 Carbide Hard Facing Stick Rod Electrode 1/4"

Couldn't load pickup availability

7355 Carbide Hard Facing Stick Rod Electrode Kit

Couldn't load pickup availability

711 Carbide Hard Facing Stick Rod Electrode 3/32"

Couldn't load pickup availability

Fender Splash Shield Push Rivet Nylon 7mm Hole

Couldn't load pickup availability

Front Bumper Push-Type Retainer Nylon 20mm

Couldn't load pickup availability

Front Bumper Drive Rivet Plastic 10mm Hole

Couldn't load pickup availability

Round Soapstone 1/4 x 5"

Couldn't load pickup availability

Wear Plates Used By Maintenance Welder 1/4X5X7

Couldn't load pickup availability

Flat Soapstone Holder Heavy Duty

Couldn't load pickup availability

Product Description

Maximize the durability of your industrial equipment with the H7 Carbide Hardfacing MIG Welding Wire. Designed to create a tough, wear-resistant layer, this welding wire is perfect for protecting metal surfaces exposed to extreme abrasion, impact, or friction. Commonly used in mining, construction, and agriculture, it extends the lifespan of components like power plant fan blades, rotary tiller blades, and screw shafts. With excellent crack resistance, it ensures reinforced parts stay strong even in flexing or fatigue-heavy applications.• All VX wires are self-shielding, saving money on gas

• Our technical team will work closely with you to determine the best product for your specific application

Significant abrasion resistance with low impact characteristics

Specifications: Moderate chrome carbide CrCHardness: Rc 60No. of Passes: Up to three

Typical Applications

• Buckets and dozer blades

• Dump beds and truck liners

• Chutes and augers

• Crushers and hammers

Technical Specifications

| Item#: | CW6086 |

|---|---|

| Welding Process | MIG |

| Type | Flux Cored |

| Diameter | 1/16 " |

| Base Metal | Carbide |

| Carbide Type | Chromium |

| Hardness | 53-60 HRC |

| Shielding Gas | No Gas |

| Polarity | DCRP |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 28.0 lb |

Product Restrictions