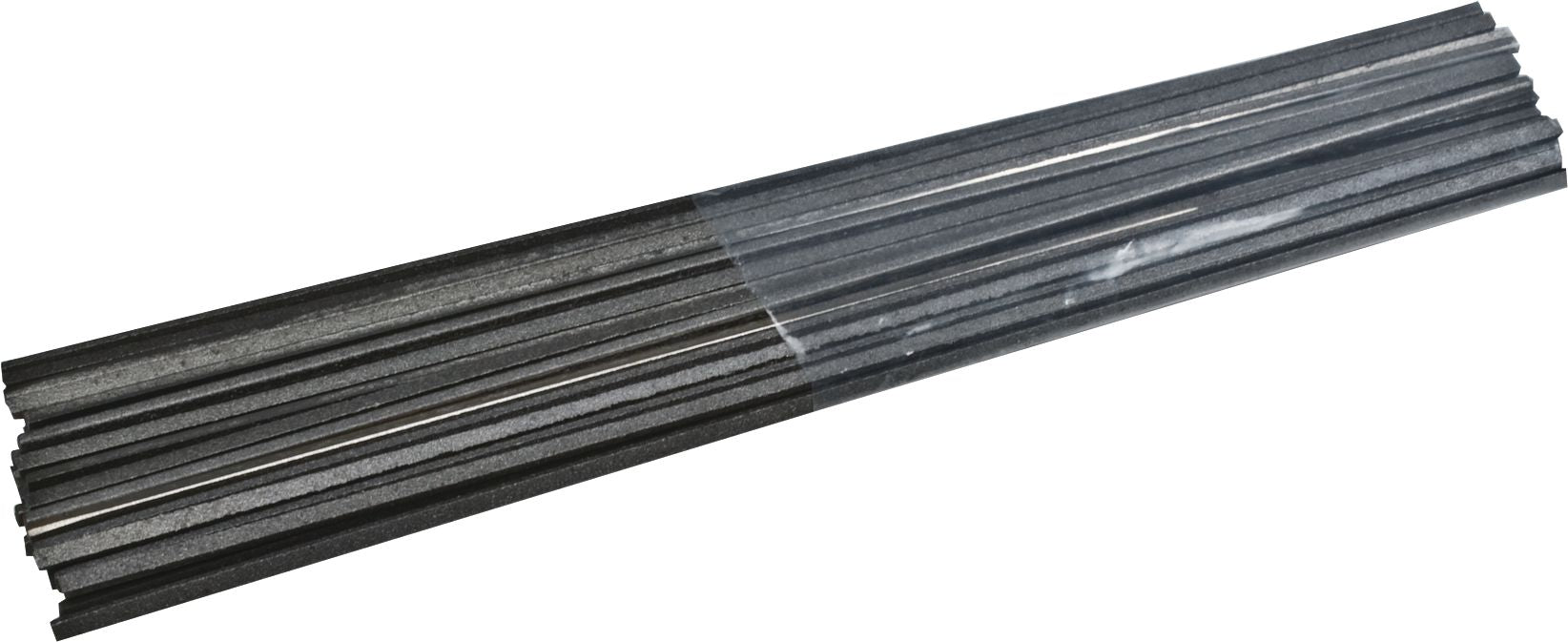

23 Copper and Steel Flux Coated Brazing Rod 1/8"

(Pack of

5)

Get strong, machinable joints on cast iron and sheet metal with the 23 Copper and Steel Flux Coated Brazing Rod. This versatile, thin-flowing alloy creates solid, dense deposits perfect for everything from auto body repairs to engine blocks, ensuring a tough repair without diluting the base metal. With a tensile strength of up to 68,000 PSI, this blue flux-coated rod provides superior welding performance for piping, gears, and more. Make your next project a success with reliable, high-strength bonds.

• Solid, dense deposits that can be machined

• Free-flowing for thin lapping and butted metal joining

• No base metal dilution making tough cast iron repairs possible

Flux Coating Color: BlueTensile Strength: Up to 68,000 PSIBonding Temperature: 1,400°F to 1,600°F (760°C to 871°C)Recommended Flux: F21 (if needed)

Typical Applications

• Sheet metal and auto body repairs

• Engine heads and blocks

• Piping, plumbing and pumps

• Gears, sprockets and pulleys

Usage ProcedureClean joint areas thoroughly. Heat metal with neutral flame until flux liquifies. Base metals should be dull red as Cronabraze™ 30F commences to penetrate the joint. Use rapid weaving motion with torch to deposit alloy drop-by-drop. Do not concentrate heat enough to melt base metal. Remove flux residue with water.

Frequently Bought Together

30 Copper and Steel Flux Coated Brazing Rod 1/16"

Couldn't load pickup availability

44 Silver Bare Brazing Rod 1/16"

Couldn't load pickup availability

41 Silver Flux Coated Brazing Rod 1/16"

Couldn't load pickup availability

Shield Push-Type Retainer with Metal Insert

Couldn't load pickup availability

Wheel House Molding Split Rivet Aluminum 3/16"

Couldn't load pickup availability

Metric Indented Hex Head Bolt with 17mm Washer

Couldn't load pickup availability

22 Cast Iron Bare Brazing Rod 3/16"

Couldn't load pickup availability

30 Copper and Steel Flux Coated Brazing Rod 3/32"

Couldn't load pickup availability

30 Copper and Steel Flux Coated Brazing Rod 1/8"

Couldn't load pickup availability

Industrial Graphite Block 2 x 10 x 12"

Couldn't load pickup availability

Wear Plates Used By Maintenance Welder

Couldn't load pickup availability

Light Weight Composite Wear Plates 24X4X13/64

Couldn't load pickup availability

Product Description

Get strong, machinable joints on cast iron and sheet metal with the 23 Copper and Steel Flux Coated Brazing Rod. This versatile, thin-flowing alloy creates solid, dense deposits perfect for everything from auto body repairs to engine blocks, ensuring a tough repair without diluting the base metal. With a tensile strength of up to 68,000 PSI, this blue flux-coated rod provides superior welding performance for piping, gears, and more. Make your next project a success with reliable, high-strength bonds.• Solid, dense deposits that can be machined

• Free-flowing for thin lapping and butted metal joining

• No base metal dilution making tough cast iron repairs possible

Flux Coating Color: BlueTensile Strength: Up to 68,000 PSIBonding Temperature: 1,400°F to 1,600°F (760°C to 871°C)Recommended Flux: F21 (if needed)

Typical Applications

• Sheet metal and auto body repairs

• Engine heads and blocks

• Piping, plumbing and pumps

• Gears, sprockets and pulleys

Usage ProcedureClean joint areas thoroughly. Heat metal with neutral flame until flux liquifies. Base metals should be dull red as Cronabraze™ 30F commences to penetrate the joint. Use rapid weaving motion with torch to deposit alloy drop-by-drop. Do not concentrate heat enough to melt base metal. Remove flux residue with water.

Technical Specifications

| Item#: | CW1002 |

|---|---|

| Welding Process | Brazing |

| Type | Flux Coating |

| Diameter | 1/8 " |

| Length | 18 " |

| Tensile Strength | 68,000 PSI |

| Melting Temperature | 1560-2000 °F |

| Color | Blue |

| Base Metal | Copper/Steel |

| Recommended Flux | F21 |

| Description | All Purpose |

| UNSPSC #: | 23271804 |

| TAA Compliant: | No |

| Weight: | 5.5 lb |

Product Restrictions