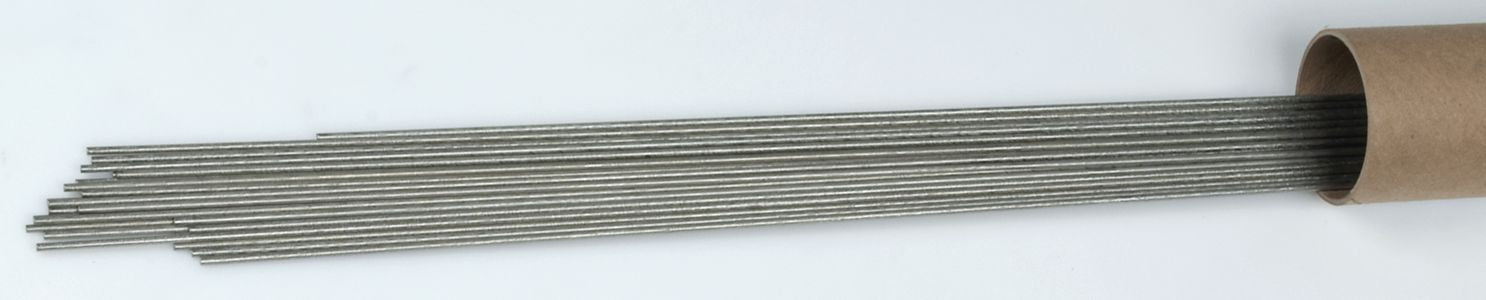

235 Cast Iron Stick Rod Electrode, Flux Coated, 80 to 120 Amps, DCSP Polarity, High Strength Welds, 1/8"

(Pack of

5)

SKU:CW1037 Item#: CW1037

All-position welding for any type of weldable cast iron repair and cast iron to steel.

Superior Advantages

• High strength welds

• Pass-over-pass welding to save time

• All-position welding may eliminate the need to dismantle equipment to perform repairs

Iron-adding

Tensile Strength: 60,000 PSIPolarity: AC or DC Reverse

235 is specifically formulated for welding on burned, rusty, corroded or otherwise contaminated cast iron parts not requiring machining.

Typical Applications

• Pump and bearing housings

• Cylinder blocks and heads

• Machine bases

• Manifolds and exhaust systems

Usage Procedure:Remove grease, scale and other impurities from weld area. Bevel cracks or breaks (70° to 90° “V”). CRONACUT™ 1100 is the fastest and easiest method to prepare section for weld repairing. Use a short to medium arc at the lowest possible amperage for best results. Employ weaving technique or stringer beads. Peen to relieve stress. Remove slag between passes. Slow cooling to room temperature recommended.

Frequently Bought Together

130 Hpm Cast Iron Machinable Electrode 1/8

Couldn't load pickup availability

211 Cast Iron Stick Rod Electrode 5/32"

Couldn't load pickup availability

889 Cast Iron Stick Rod Electrode 1/8"

Couldn't load pickup availability

Fender Liner Screw Grommet Nylon M5.5

Couldn't load pickup availability

Front Bumper Push-Type Retainer Nylon 10mm

Couldn't load pickup availability

Front Rear Bumper Specialty Rivet 3.2mm

Couldn't load pickup availability

Heat Stick 1050F Degrees

Couldn't load pickup availability

Wear Plates Used By Maintenance Welder 1/4X4X5

Couldn't load pickup availability

Wear Plates Used By Maintenance Welder 3/16X3X4

Couldn't load pickup availability

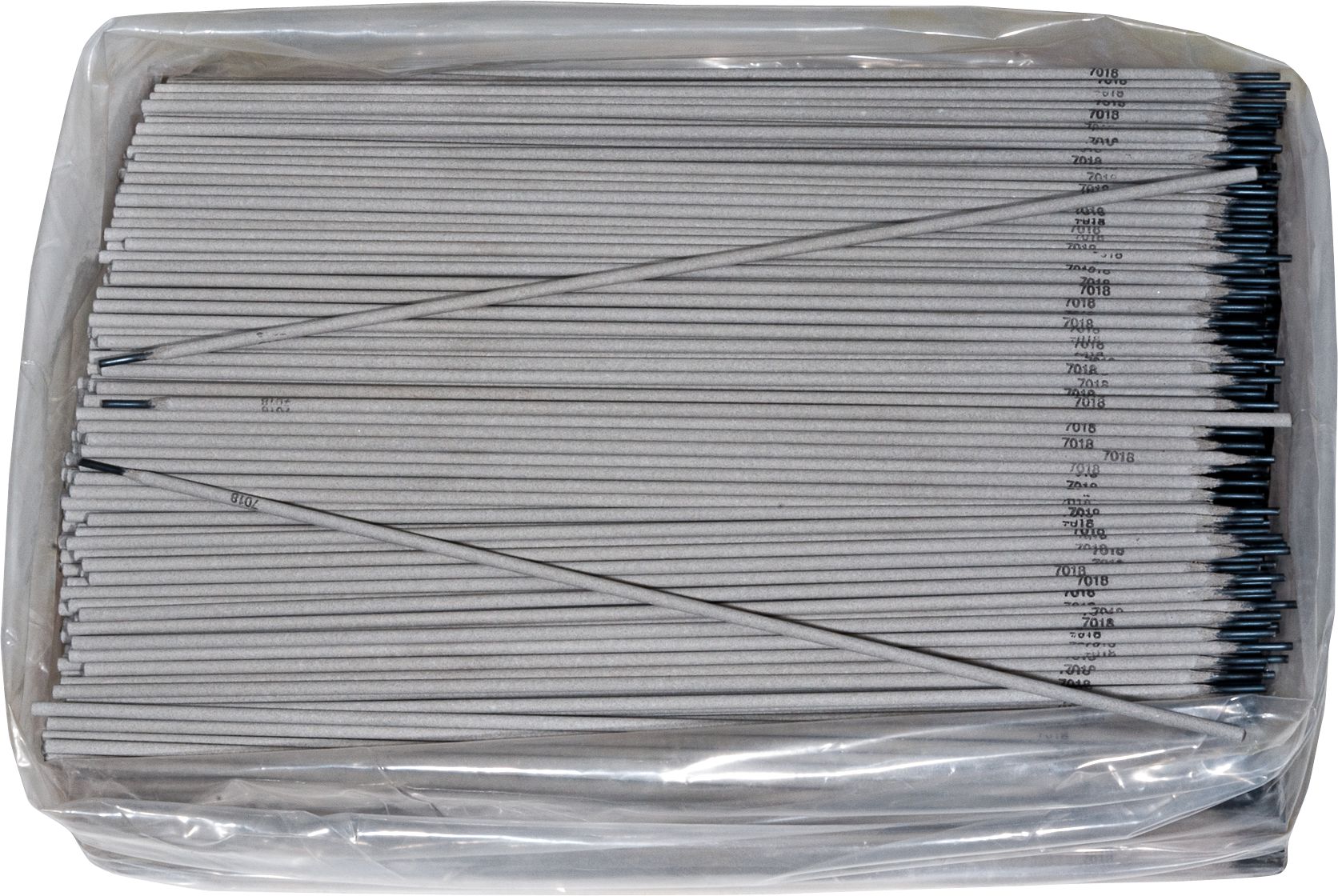

E7018 Mild/Carbon Steel Stick Electrode 1/8"

Couldn't load pickup availability

211 Cast Iron TIG Wire 3/32"

Couldn't load pickup availability

E7018 Mild/Carbon Steel Stick Electrode 3/32"

Couldn't load pickup availability

Product Description

All-position welding for any type of weldable cast iron repair and cast iron to steel.Superior Advantages

• High strength welds

• Pass-over-pass welding to save time

• All-position welding may eliminate the need to dismantle equipment to perform repairs

Iron-adding

Tensile Strength: 60,000 PSIPolarity: AC or DC Reverse

235 is specifically formulated for welding on burned, rusty, corroded or otherwise contaminated cast iron parts not requiring machining.

Typical Applications

• Pump and bearing housings

• Cylinder blocks and heads

• Machine bases

• Manifolds and exhaust systems

Usage Procedure:Remove grease, scale and other impurities from weld area. Bevel cracks or breaks (70° to 90° “V”). CRONACUT™ 1100 is the fastest and easiest method to prepare section for weld repairing. Use a short to medium arc at the lowest possible amperage for best results. Employ weaving technique or stringer beads. Peen to relieve stress. Remove slag between passes. Slow cooling to room temperature recommended.

Technical Specifications

| Item#: | CW1037 |

|---|---|

| Welding Process | Stick |

| Type | Flux Coated |

| Diameter | 1/8 " |

| Tensile Strength | 60,000 PSI |

| Base Metal | Cast Iron |

| Polarity | DCSP |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 5.24 lb |

Product Restrictions