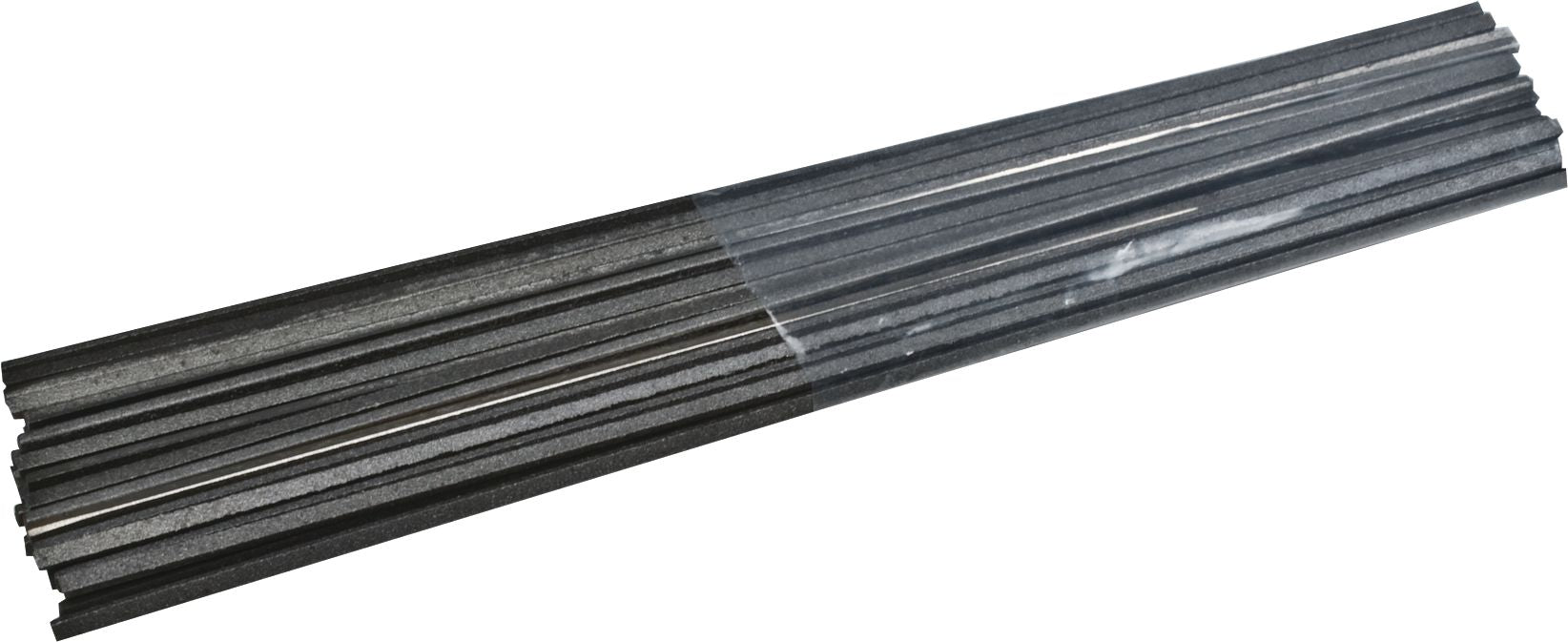

44 Silver Bare Brazing Rod 3/32"

(Pack of

2)

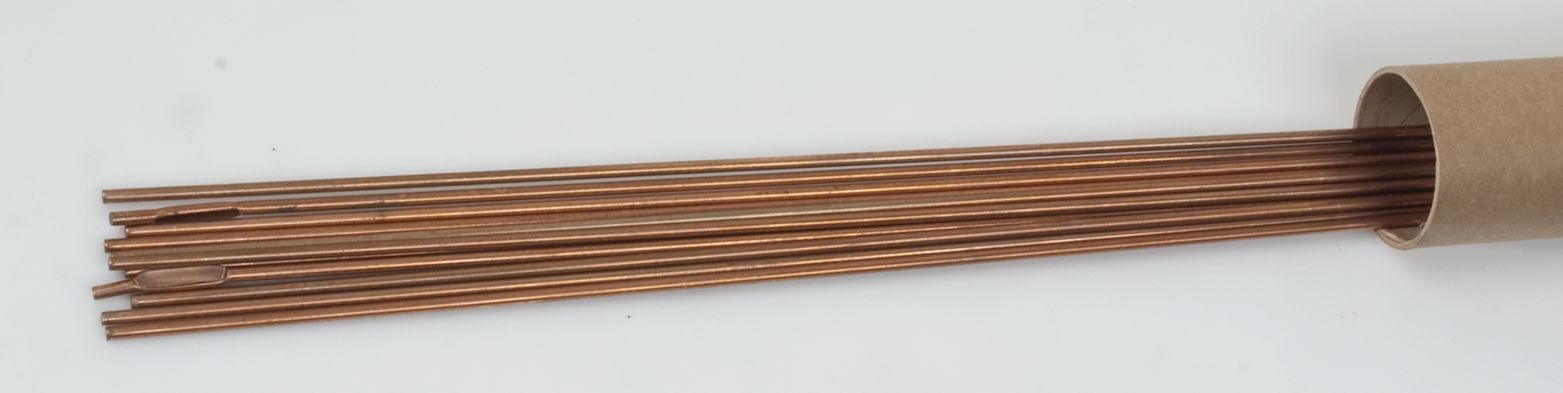

Tackle your welding projects with the 54 Al44 Silver Bare Brazing Rod, engineered specifically for copper and brass applications that demand both strength and precision. This high-performance rod delivers superior joint integrity while offering significant cost savings compared to traditional silver alloys, making it the smart choice for professional welders who refuse to compromise on quality. Operating within a brazing range of 1,350°F to 1,550°F, it excels in electrical contacts, copper wire splicing, and brass fittings with a color match that ensures seamless, professional-looking results. Whether you're joining copper pipes or bonding copper to steel, this reliable brazing rod provides the durability and performance your welding projects deserve.

• High strength

• Lower cost compared to silver alloys

• Good color match

Brazing Range: 1,350°F to 1,550°F (732°C to 843°C)Recommended Flux: F40 (if needed)

Typical Applications

• Electrical contacts

• Copper wire splicing

• Brass and bronze fittings

• Copper pipes

• Copper to steel

Usage ProcedureUse a slightly carburizing flame to obtain a free-flowing bead. Cronabraze™ 44 does not require fusion of the base metal. For joining copper to copper, no flux is required, but with brass or bronze, F40 flux is needed for a strong, sure bond. It is recommended that 2" to 3" of distance be maintained between the flame cone and the base metal for best results.

Frequently Bought Together

201 The Elite Blue Flux Coated Brazing Alloy 1/16

Couldn't load pickup availability

54 Aluminum Flux Cored Brazing Rod 1/8"

Couldn't load pickup availability

22 Cast Iron Bare Brazing Rod 3/16"

Couldn't load pickup availability

201 The Elite Bare Brazing Alloy 1/16X18

Couldn't load pickup availability

44 Silver Bare Brazing Rod 1/16"

Couldn't load pickup availability

Torrent Frame Front

Couldn't load pickup availability

One-Handed Reciprocating Saw

Couldn't load pickup availability

345 Tool Steel TIG Wire 5/32"

Couldn't load pickup availability

Radiator Grille Nut M4.2-1.41

Couldn't load pickup availability

Bumper Drive Rivet Plastic 10mm Hole

Couldn't load pickup availability

Rocker Molding Clip with Sealer Nylon Gray 12mm

Couldn't load pickup availability

Heat Stick 1050F Degrees

Couldn't load pickup availability

Wear Plates Used By Maintenance Welder 1/4X4X5

Couldn't load pickup availability

Wear Plates Used By Maintenance Welder 3/16X3X4

Couldn't load pickup availability

Product Description

Tackle your welding projects with the 54 Al44 Silver Bare Brazing Rod, engineered specifically for copper and brass applications that demand both strength and precision. This high-performance rod delivers superior joint integrity while offering significant cost savings compared to traditional silver alloys, making it the smart choice for professional welders who refuse to compromise on quality. Operating within a brazing range of 1,350°F to 1,550°F, it excels in electrical contacts, copper wire splicing, and brass fittings with a color match that ensures seamless, professional-looking results. Whether you're joining copper pipes or bonding copper to steel, this reliable brazing rod provides the durability and performance your welding projects deserve.• High strength

• Lower cost compared to silver alloys

• Good color match

Brazing Range: 1,350°F to 1,550°F (732°C to 843°C)Recommended Flux: F40 (if needed)

Typical Applications

• Electrical contacts

• Copper wire splicing

• Brass and bronze fittings

• Copper pipes

• Copper to steel

Usage ProcedureUse a slightly carburizing flame to obtain a free-flowing bead. Cronabraze™ 44 does not require fusion of the base metal. For joining copper to copper, no flux is required, but with brass or bronze, F40 flux is needed for a strong, sure bond. It is recommended that 2" to 3" of distance be maintained between the flame cone and the base metal for best results.

Technical Specifications

| Item#: | CW1012 |

|---|---|

| Welding Process | Brazing |

| Type | Bare |

| Diameter | 3/32 " |

| Length | 36 " |

| Melting Temperature | 1350-1550 °F |

| Color | Copper |

| Base Metal | Silver |

| Recommended Flux | F40 |

| Description | Copper/Brass |

| UNSPSC #: | 23271804 |

| TAA Compliant: | Yes |

| Weight: | 2.0 lb |

Product Restrictions