52 Aluminum/Zinc Bare Brazing Rod 1/8"

(Pack of

2)

A selection of alloys for joining all types of aluminum.

Superior Advantages

• Products for joining and buildup

• Easy to apply

High-strength, self-fluxing

Tensile Strength: 40,000 PSIBond Strength: 28,000 PSIApplication Temperature: 720°F (382°C)

Typical Applications

• Aluminum frames

• Tubing and piping

• Ornamental aluminum

• Cast aluminum

Usage ProcedureHeat base metal with 1-X acetylene feather flame. Melt off small amount of Cronabraze Eagle™ 52 and scrub (tin) area of repair using a clean stainless steel wire brush. Use circular motion of torch when applying buildup or repair alloy. Copper or carbon block is suggested as a chill bar when soldering thin sections. No flux is required.

Technical TipMaximum bonding requires getting to the base metal under the oxide layer present on all aluminum. To bond to virgin metal, scrub the bonding area with molten ‘52’ alloy or scratch the area with the ‘52’ alloy with the base metal at application temperature. Heavy oxide layers can be easily removed with ‘Flex’ grinding wheels.After tinning, bring filler to surface at 90° angle and manipulate torch in a circular motion at 45°. Avoid overheating base metal. Use clean torch tip to p

Frequently Bought Together

53 Pot Metal Bare Brazing Rod 1/16"

Couldn't load pickup availability

53 Pot Metal Bare Brazing Rod 1/8"

Couldn't load pickup availability

40 High Silver Flux Coated Brazing Rod 1/16"

Couldn't load pickup availability

44 Silver Bare Brazing Rod 3/32"

Couldn't load pickup availability

51 High Silver Flux Coated Brazing Rod 1/16"

Couldn't load pickup availability

9" Hi-Level Heavy-Duty Power Jaw Plier-Cutter

Couldn't load pickup availability

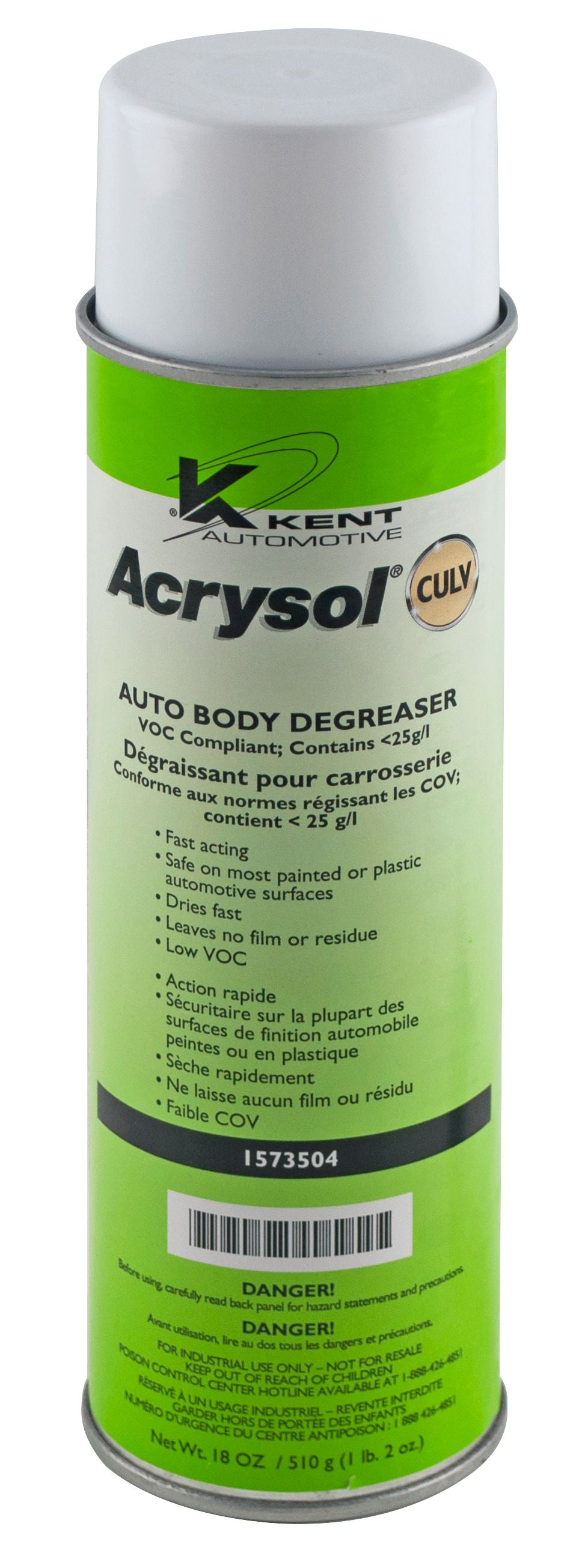

Acrysol-CULV Auto Body Degreaser 18oz

Couldn't load pickup availability

Round Mini Turbo Mixer with Integrated Nut

Couldn't load pickup availability

High-Tech Seam Sealer Clear 5fl.oz

Couldn't load pickup availability

Front Fender Push-Type Retainer Nylon 20mm

Couldn't load pickup availability

Fender Apron Drive Rivet 8mm Hole

Couldn't load pickup availability

AWS E71T-11 Carbon Steel MIG Flux Core Welding Wire .035" 2lb

Couldn't load pickup availability

Flint For Spring Loaded Trigger Torch Lighter

Couldn't load pickup availability

Cronatron Welding Guide

Couldn't load pickup availability

Product Description

A selection of alloys for joining all types of aluminum.Superior Advantages

• Products for joining and buildup

• Easy to apply

High-strength, self-fluxing

Tensile Strength: 40,000 PSIBond Strength: 28,000 PSIApplication Temperature: 720°F (382°C)

Typical Applications

• Aluminum frames

• Tubing and piping

• Ornamental aluminum

• Cast aluminum

Usage ProcedureHeat base metal with 1-X acetylene feather flame. Melt off small amount of Cronabraze Eagle™ 52 and scrub (tin) area of repair using a clean stainless steel wire brush. Use circular motion of torch when applying buildup or repair alloy. Copper or carbon block is suggested as a chill bar when soldering thin sections. No flux is required.

Technical TipMaximum bonding requires getting to the base metal under the oxide layer present on all aluminum. To bond to virgin metal, scrub the bonding area with molten ‘52’ alloy or scratch the area with the ‘52’ alloy with the base metal at application temperature. Heavy oxide layers can be easily removed with ‘Flex’ grinding wheels.After tinning, bring filler to surface at 90° angle and manipulate torch in a circular motion at 45°. Avoid overheating base metal. Use clean torch tip to p

Technical Specifications

| Item#: | CW1735 |

|---|---|

| Welding Process | Brazing |

| Type | Bare Brazing Rod |

| Diameter | 1/8 " |

| Length | 18 " |

| Tensile Strength | 28,000 PSI |

| Melting Temperature | 720 °F |

| Base Metal | Aluminum/Zinc |

| UNSPSC #: | 23271804 |

| TAA Compliant: | Yes |

| Weight: | 2.5 lb |

Product Restrictions