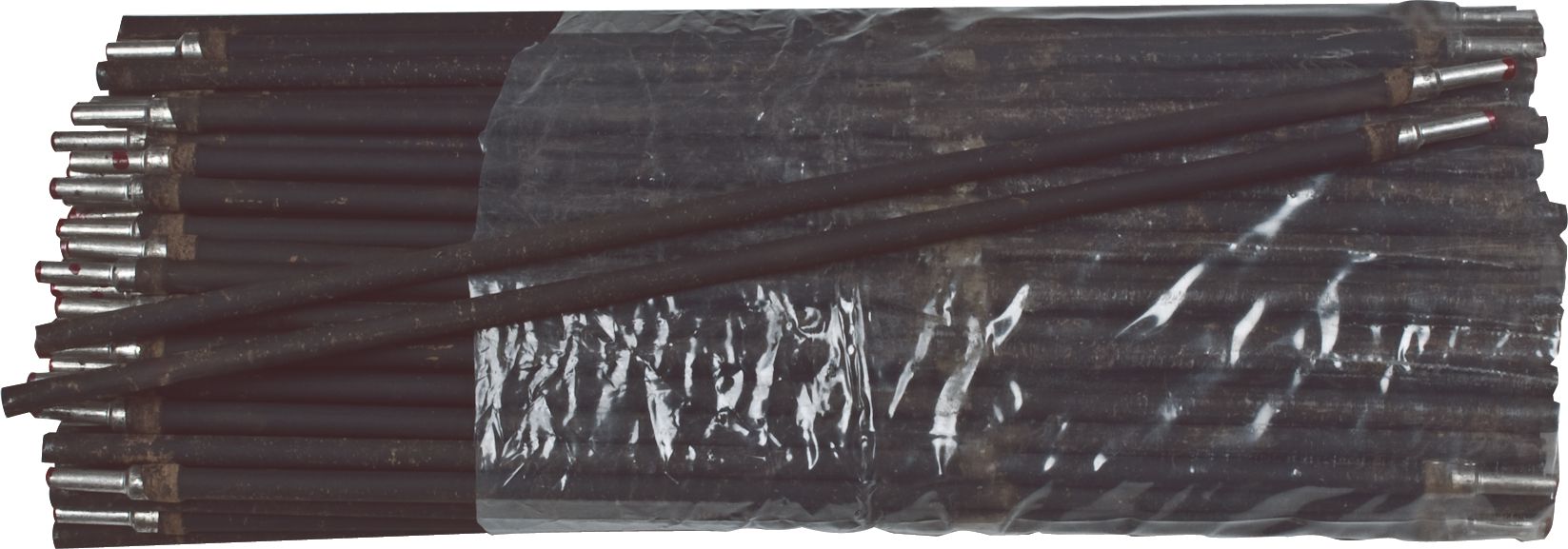

676 Flux Corred Wire Optional Sheilding Gas 100% Co2 Up 64Rc In Hardness For Carbon And Low Alloy And Manganese Steels

(Pack of

33)

A specially formulated flux cored wire designed to produce extremely wear-resistant deposits. The high concentration of small primary carbides greatly improves toughness and abrasion resistance over conventional chromium carbide alloys. Can be applied to carbon, low alloy, and manganese steels and can be used in hot wear applications up to 900°F/482°C.

• Smooth arc for superior control

• No gas required

• Deposit cross-checks readily

• Resists hot wear up to 900°F/482°C

• Hardness: Up to 64Rc

• Max Number of Passes: 2

• Impact Resistance: Moderate

• Machinability: Grind only

• Magnetic: – On Carbon Steel: Slightly – On Manganese Steel: No

• Hot Wear Applications: Up to 900°F/482°C

• Current: DCEP (DC+)

• Shielding Gas: Optional, 100% CO2

Frequently Bought Together

750 Martensitic Stick Rod Electrode 5/32"

Couldn't load pickup availability

172 Intermediate Abrasion And Impact Alloy 5/32X18

Couldn't load pickup availability

711 Carbide Hard Facing Stick Rod Electrode 5/32"

Couldn't load pickup availability

7350 Carbide Hard Facing Stick Rod Electrode 1/2"

Couldn't load pickup availability

7230 Carbide Hard Facing Stick Rod Electrode 3/8"

Couldn't load pickup availability

7370 Carbide Hard Facing Stick Rod Electrode 3/8"

Couldn't load pickup availability

Push-Type Retainer Nylon 16 x 19mm

Couldn't load pickup availability

Bumper Push-Type Retainer Nylon 18mm

Couldn't load pickup availability

Front Fender Liner Push-Type Retainer Nylon 20mm

Couldn't load pickup availability

Cap Whip-Lead Connector #4 to #1

Couldn't load pickup availability

Oxygen Safety Cap Heavy Duty

Couldn't load pickup availability

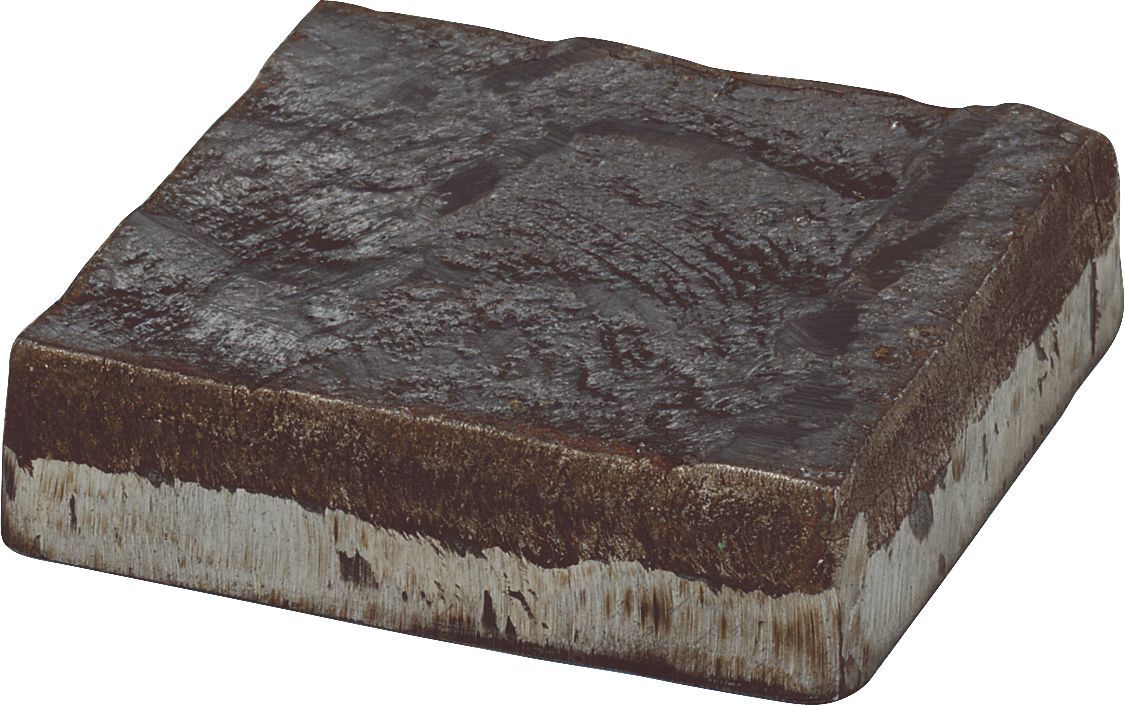

1/2 on 1/2 Dimension I Double Pass Overlay

Couldn't load pickup availability

Product Description

A specially formulated flux cored wire designed to produce extremely wear-resistant deposits. The high concentration of small primary carbides greatly improves toughness and abrasion resistance over conventional chromium carbide alloys. Can be applied to carbon, low alloy, and manganese steels and can be used in hot wear applications up to 900°F/482°C.• Smooth arc for superior control

• No gas required

• Deposit cross-checks readily

• Resists hot wear up to 900°F/482°C

• Hardness: Up to 64Rc

• Max Number of Passes: 2

• Impact Resistance: Moderate

• Machinability: Grind only

• Magnetic: – On Carbon Steel: Slightly – On Manganese Steel: No

• Hot Wear Applications: Up to 900°F/482°C

• Current: DCEP (DC+)

• Shielding Gas: Optional, 100% CO2

Technical Specifications

| Item#: | EG67680045 |

|---|---|

| Welding Process | Flux-Core Arc Welding |

| Type | Flux-Cored Wire |

| Diameter | .045 " |

| Base Metal | Carbon And Alloy Steels |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 37.49 lb |

Product Restrictions